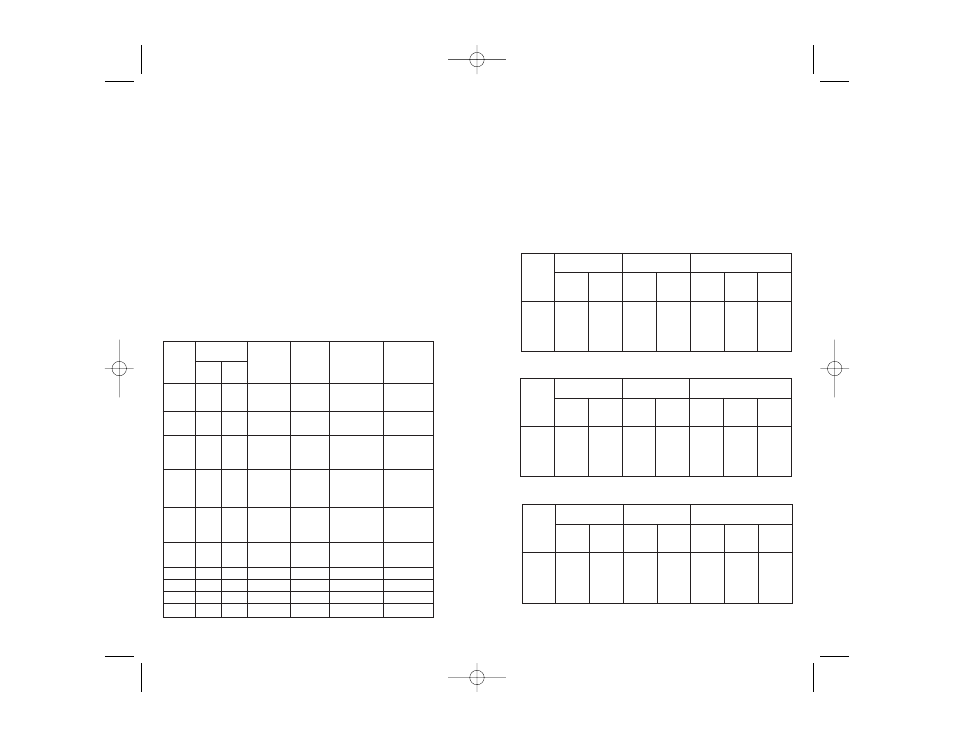

Mini-eegor, Radii tables, For imc conduit (dimensions in inches) – Gardner Bender Guide to Profitable Bending User Manual

Page 13: Rigid steel and aluminum

IMC Size

IMC Bend

IMC Bend

Outside Dia.

Centerline

Inside

Bending

Nominal Actual

Frac.

Radius

Radius

Shoe

Size

O.D.

O.D

A

B

Type Shoe

Model No.

4

3

⁄

8

3

31

⁄

32

Cyclone

®

B2000

3

1

⁄

4

2

13

⁄

16

Mechanical

BR57510

5

5

⁄

16

4

25

⁄

32

Cyclone

®

B2000

5

4

1

⁄

2

Mechanical

BR57510

6

7

⁄

32

5

9

⁄

16

Cyclone

®

B2000

1

1.290

1

19

⁄

64

5

3

⁄

4

5

1

⁄

16

Mini-Eegor™

BZ259

6

7

⁄

16

5

3

⁄

4

Mechanical

BR57510

7

23

⁄

32

6

7

⁄

8

Cyclone

®

B2000

1

1

⁄

4

1.638

1

41

⁄

64

7

5

⁄

16

6

1

⁄

2

Mini-Eegor™

BZ260

8

1

⁄

16

7

1

⁄

4

Mechanical

BR12515

8

7

⁄

32

7

9

⁄

32

Cyclone

®

B2000

1

1

⁄

2

1.883

1

57

⁄

64

8

7

⁄

32

7

9

⁄

32

Mini-Eegor™

BZ261

9

1

⁄

16

8

5

⁄

8

Mechanical

BR12515

2

2.360

2

23

⁄

64

9

15

⁄

32

8

9

⁄

32

Cyclone

®

B2000

9

3

⁄

16

8

Mini-Eegor™

BZ262

2

1

⁄

2

2.857

2

55

⁄

64

10

1

⁄

2

9

1

⁄

16

Eegor™

BZ25

3

3.476

3

15

⁄

32

13

11

1

⁄

4

Eegor™

BZ30

3

1

⁄

2

3.971

3

15

⁄

32

17

1

⁄

2

15

1

⁄

2

Eegor™

BZ35

4

4.466

4

15

⁄

32

20

17

3

⁄

4

Eegor™

BZ40

1

⁄

2

.815

13

⁄

16

3

⁄

4

1.029 1

1

⁄

16

Bending Shoe Radii Table for

Benders on pages 14 - 41

These radii tables are provided for your general information. The

Centerline and Inside radius are shown for each shoe.

In selecting a bender set, compare the shoe model numbers shown in

the bender selection charts to these tables for complete shoe

radii information.

Three bending shoe tables are shown:

1. For thinwall (EMT) conduit. See chart on page 45.

2. For IMC conduit and pipe. See chart below.

3. For steel and aluminum rigid conduit and pipe. See chart on

page 46.

(Bending shoe tables for Eegor™ hydraulic benders are on page 11,

for Mini-Eegor™ hydraulic benders see page 13.)

44

For IMC Conduit (Dimensions in inches)

13

Mini-Eegor

™

Radii Tables

These radii tables for EMT, IMC and rigid conduit are provided for

general information. The centerline and inside radius are shown for

each shoe.

In selecting a bender set, compare the shoe model numbers shown in

the bender selection charts to these tables for complete shoe

radii information.

Lubricate rollers, when needed, with molybdenum disulfide paste only

(such as Dow Corning’s Molykote #G-n paste, or equivalent.)

For heavy use, lubricate rollers weekly.

Note:

Graphite formulations are not equivalent lubrications.

* Actual bend radii are slightly larger because of pipe springback.

Pipe Outside

Pipe Bend

Diameters

Radii*

Model Numbers

Nominal

A

B

Conduit

Frac-

Center-

Inside

Bending Follower

Size

Actual

tional

line

Bend

Shoe

Bar

U-strap

1"

1.315

1

5

⁄

16

5

3

⁄

4

5

1

⁄

16

BZ259

—

BZ253

1

1

⁄

4

"

1.660

2

5

⁄

16

7

1

⁄

4

6

5

⁄

8

BZ260

—

BZ254

1

1

⁄

2

"

1.900

1

29

⁄

32

8

1

⁄

8

7

3

⁄

16

BZ261

—

BZ255

2"

2.375

2

3

⁄

8

9

1

⁄

16

7

7

⁄

8

BZ262

BZ258

BZ256

Rigid Steel and Aluminum

Pipe Outside

Pipe Bend

Diameters

Radii*

Model Numbers

Nominal

A

B

Conduit

Frac-

Center-

Inside

Bending Follower

Size

Actual

tional

line

Bend

Shoe

Bar

U-strap

1"

1.290

1

19

⁄

64

5

3

⁄

4

5

1

⁄

16

BZ259

—

BZ253

1

1

⁄

4

"

1.638

1

41

⁄

64

7

1

⁄

4

6

5

⁄

8

BZ260

—

BZ254

1

1

⁄

2

"

1.883

1

57

⁄

64

8

1

⁄

8

7

3

⁄

16

BZ261

— BZ255

2"

2.360

2

23

⁄

64

9

1

⁄

16

7

7

⁄

8

BZ262

BZ258

BZ256

IMC

Pipe Outside

Pipe Bend

Diameters

Radii*

Model Numbers

Nominal

A

B

Conduit

Frac-

Center-

Inside

Bending Follower

Size Actual

tional

line

Bend

Shoe

Bar

U-strap

1"

1.163

1

5

⁄

32

5

3

⁄

4

5

3

⁄

16

BZ259

—

BZ253

1

1

⁄

4

"

1.510

1

33

⁄

64

7

1

⁄

4

6

5

⁄

8

BZ260

BZ1343

BZ254

1

1

⁄

2

"

1.740

1

47

⁄

64

8

1

⁄

8

7

1

⁄

4

BZ261

BZ1344

BZ255

2"

2.197

2

13

⁄

64

9

1

⁄

6

8

BZ262

BZ1345

BZ256

EMT

E-507 Guide to Profitable Bending rA.qxd 10/19/09 3:17 PM Page 25