Offset bend instructions for mechanical sidewinder, Benders, Important – Gardner Bender Guide to Profitable Bending User Manual

Page 15: Assembly, Bending

42

Offset Bend Instructions for

Mechanical Sidewinder

®

Benders

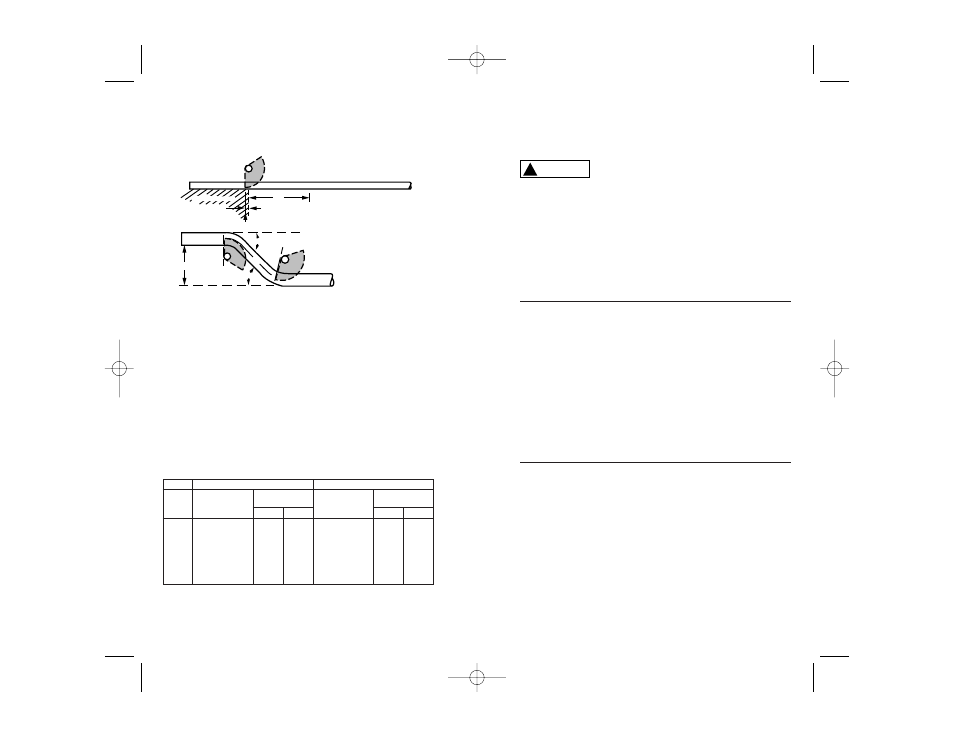

1. Locate first bend at the edge of the step over which conduit will be

formed. Place first mark 1

1

⁄

2

” short of where bend is to start (see

Figure 1 above).

2. Multiply known (H) dimension by multiplier shown in chart below

under size of conduit and desired angle.

3. To obtain measurement (B), add correction factor in chart to the

figure obtained in step 2 and mark (B) as illustrated.

4. Place conduit or thinwall in bender, aligning first bend mark with

forward edge of bending shoe. Prodeed to bend, reading angle on

indicator.

5. Rotate conduit or thinwall 180˚ and align second bend mark with

forward edge of bending shoe bend mark with the forward edge of

bending shoe. Proceed to bend, reading angle on indicator.

30°

45°

Correction

Correction

Size

Multiplier

Factor

Multiplier

Factor

Rigid

EMT

Rigid

EMT

1

⁄

2

2

0

0

1.4

0

0

3

⁄

4

2

0

0

1.4

0

0

1

2

0

0

1.4

0

0

1

1

⁄

4

2

0

1

⁄

2

1.4

0

1

⁄

2

1

1

⁄

2

2

0

7

⁄

16

1.4

0

7

⁄

16

2

2

0

0

1.4

0

0

+

Edge Of Step

(Obstacle)

1 /

1

2

˝

1st Mark

B

Figure 1

Figure 2

Angle

B

Angle

H

Edge

of Shoe

First Bend

Edge of Shoe

Second Bend

IMPORTANT

Before starting a bend, make sure pivot pins are through the pivot

assemblies, the bottom frame plate and locked firmly in the hole.

When activating the hydraulic pump, the operator must stand at

the cylinder side of the bender. Due to bending forces it is not

recommended to operate any bender from the front or frame side

of the bender.

During bending, watch the optic angle gauge until the gauge

indicating line for the desired angle is aligned with the mark on

the frame. Due to conduit spring back, it is usually

necessary to bend slightly more than the required angle.

Use Stub-up, Kick Bend and Offset Bend Charts on pages 20 thru 24.

ASSEMBLY

1. Thread the hydraulic cylinder into the cylinder support block on the

bending frame.

2. Attach hoses to pump valve; connect cylinder hose

① to valve port

①; connect cylinder hose ➁ to valve port ➁.

3. Select bending shoe for conduit size. Each shoe is marked for sizes.

An arrow indicates the center of bend to be made.

4. Insert and lock bending shoe onto cylinder plunger. Use “U” shaped

lock pin. Refer to Conduit Size Chart.

BENDING

1. Place conduit into bender frame and against the shoe groove.

2. Attach the optic angle gauge to the pivot assembly being installed in

the frame where the scribed line runs between each hole. Position

the pivot assembly with the follower bar (grooved side) toward the

conduit. Be sure follower bar is centered within the pivot assembly.

3. Secure the pivot assemblies with pivot pins. Press release knob on

the pin and insert it through the top frame, pivot assembly and

through the bottom frame. Pin retaining balls must be under the

bottom frame.

15

!

CAUTION

continued on next page

E-507 Guide to Profitable Bending rA.qxd 10/19/09 3:17 PM Page 29