Offset bend instructions for gb thinwall benders, Important – Gardner Bender Guide to Profitable Bending User Manual

Page 19

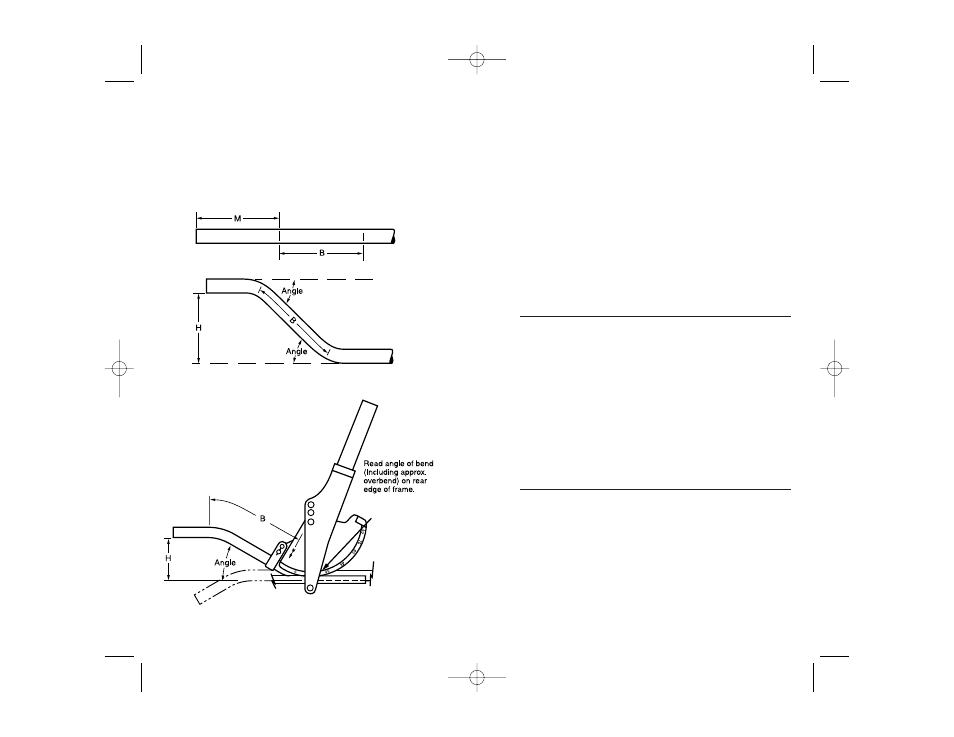

Offset Bend Instructions for

GB Thinwall Benders

38

19

IMPORTANT

Before starting a bend, be sure pivot pins are through the bottom

frame plate and locked in position to properly anchor.

When actuating pump, either hand or electric, operator should

position himself on the cylinder side. It is not recommended that

any bender be operated from the front position.

As bend is generated, watch optic angle gauge until desired angle

of bend is reached. Because of conduit springback, it will be

necessary to go a bit beyond the desired angle.

1. Thread hydraulic cylinder into cylinder support block on

bending frame.

2. Attach hoses to pump valve. Connect hose

① to cylinder port

① — hose ➁ to cylinder port ➁.

3. Select bending shoe for conduit to be bent. Each shoe is marked

for size and has an arrow, indicating the center point of bend to

be made.

4. Insert and lock selected bending shoe on cylinder plunger with

U-shaped lock pin.

1. Place conduit in bender frame.

2. Attach optic angle gauge to the top of pivot shoe as shown. Pin

locator on top of pivot shoes locate for correct setting of zero before

bending cycle.

3. Mount other pivot shoe. Both pivot shoes are marked for various

pipe sizes. The markings on pivot shoes must correspond to the pipe

size being bent and face the pipe.

4. Angle gauge should now read at zero when read along line scribed

on bender frame.

5. Lock both pivot shoes in position with push-button pivot pins. Pivot

pin is operated by pushing down on button with thumb while

grasping cross handle. Be sure pivot pins are inserted through

corresponding marked pipe size holes.

6. Turn pump valve as shown for manual valve and proceed to bend. If

electric push-button model, push "advance" button.

1. Retract cylinder plunger slightly by turning pump valve in opposite

direction of outward bending stroke. This will take pressure off pivot

shoes and pins. If electric push-button model, jog retract button.

2. Remove either one or both of the pivot shoes and reposition one

pivot pin in proper pipe-size “eject hole” where the pin will restrain

the conduit, not the shoe, as they retract. Four inch one-shot

frames and 5-inch frames have two eject holes. Use both holes.

3. Now fully retract the cylinder plunger. Bending shoe and conduit will

retract together until conduit meets pivot pin. On contact, conduit will

strip from shoe.

4. Remove other pivot pin and pivot shoe to remove conduit

from bender.

E-507 Guide to Profitable Bending rA.qxd 10/19/09 3:17 PM Page 37