Gardner bender thinwall bender sets – Gardner Bender Guide to Profitable Bending User Manual

Page 22

Gardner Bender

Thinwall Bender Sets

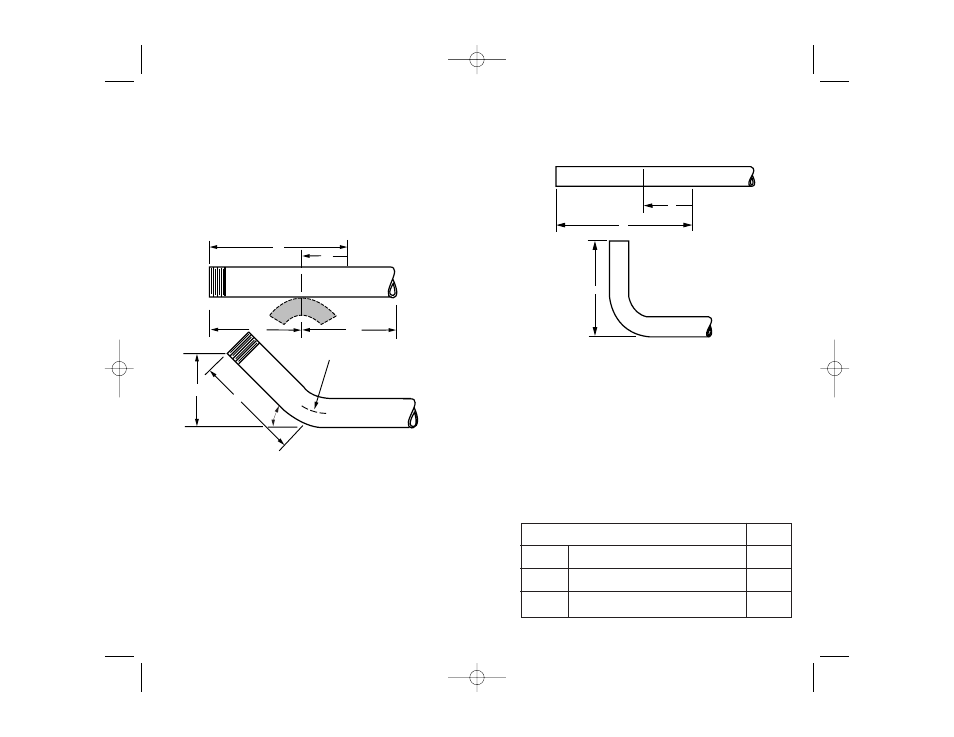

1. Mark desired turn-up dimension (H) on straight length of thinwall.

Note: (H) Must be at least 2" longer than Set-back (S) shown

on chart.

2. Locate the size of thinwall you are bending in chart and

obtain dimension (S).

3. Measure back dimension (S) and mark thinwall.

4. Place thinwall in bender so mark (S) aligns with arrow on bending

shoe. Proceed to bend, reading angle on shoe at rear edge of

bending frome. (Angle on shoe includes approximate springback.)

S

H

H

35

Thinwall Nominal

Set-back

Size (in.)

(S)

Actual O.D.- 1.510

Centerline Radius of Bend-7

1

⁄

4

"

Actual O.D.-1.740

Centerline Radius of Bend - 8

1

⁄

8

"

Actual O.D. - 2.197

Centerline Radius of Bend - 9

1

⁄

8

"

8

7

⁄

8

"

9

3

⁄

8

"

10

3

⁄

4

"

1

1

⁄

4

1

1

⁄

2

2

Kick Bend

Instructions for

One-shot PVC-coated

Conduit Benders

1. From the Diagonal Distance Chart (pg. 23), find diagonal distance

(D) which corresponds with the desired turn-up dimension (H). Mark

distance (D) from the end of a straight length of conduit.

2. Locate the size of conduit in chart to obtain Set-back measurement

(S) under the angle of bend desired.

3. Mark off measurement (S) on conduit as illustrated.

Mark (S) cannot be closer to ends of conduit than minimum distance

(L) shown in chart or ends will not be supported on the pivot shoes.

4. Place conduit in bender so mark aligns with arrow on bending shoe.

Proceed to bend, reading desired angle on optic angle gauge.

L

L

D

S

Angle

R

H

D

22

E-507 Guide to Profitable Bending rA.qxd 10/19/09 3:17 PM Page 43