Veris Technologies 3150 Soil EC Mapping System - Operating Instructions User Manual

Page 21

Pub. # OM17-EC

3-3

Installation:

1) Locate power unit in desired location in towing vehicle. If the unit is to be used on a dedicated

unit, we advise anchoring it securely to prevent tipping or damage in rough field conditions.

Mounting holes are located on each side of base.

2) Connect ground (black) power cable to negative post on towing vehicle battery.

3) Connect power (red) cable directly to the positive post on the battery. Quick connect to power

unit.

4) Remove the shipping plug from the reservoir and install breather cap. ( a plug will be installed if

shipped via UPS).

5) Lower implement to the surface and remove ratchet jack. (Note: Cylinder may have been

previously installed at factory).

6) Connect hoses to power unit. Note that the quick couplers are labeled for proper connection.

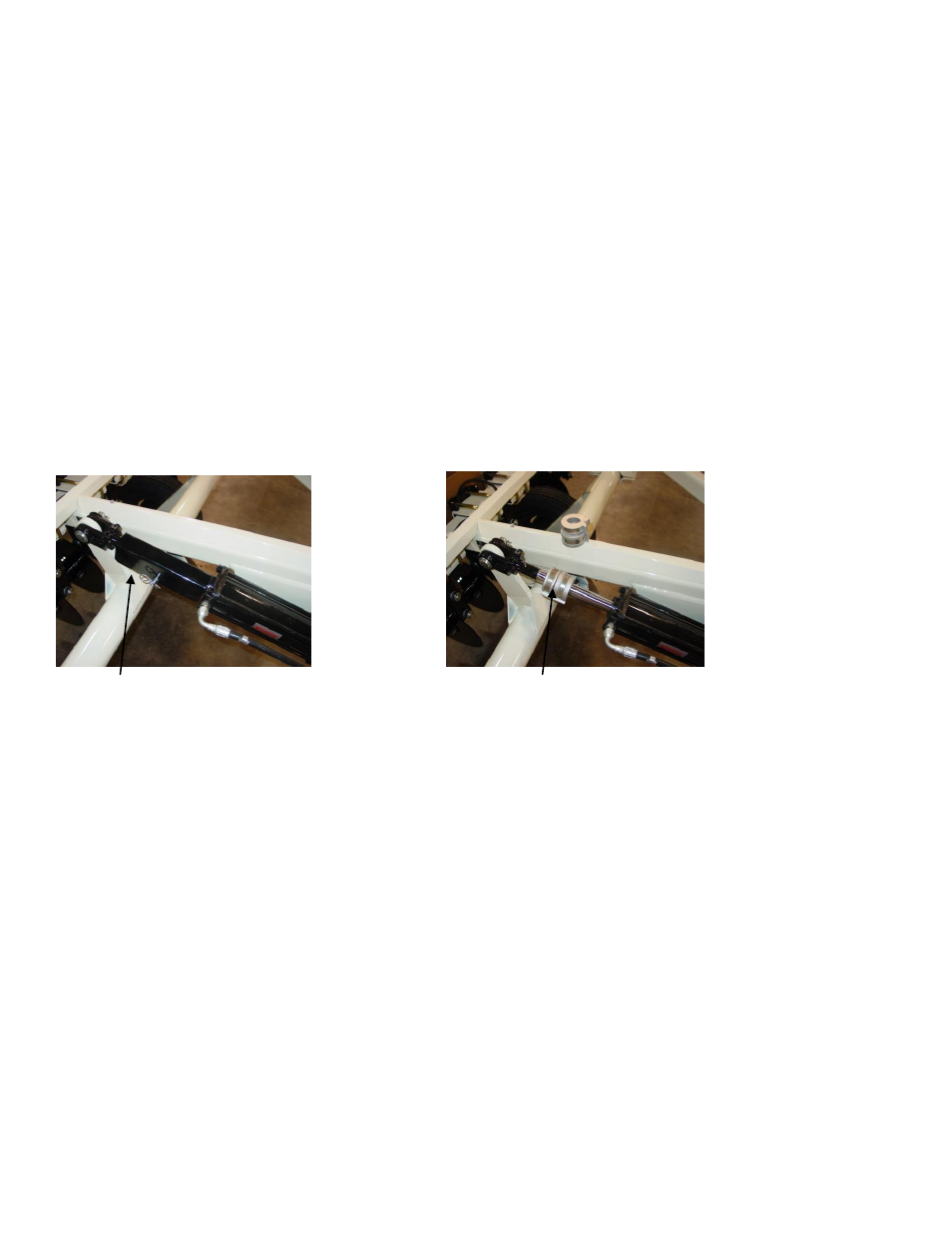

7) Install the cylinder to the implement as shown below, with the rod end to the rear and the

cylinder barrel in the lower position; with the hose fittings outward from the center.

Figure 6

Figure 7

Transport lock

Depth Collars

Operation:

1) The remote control offers simple operation of the power unit. Push button to raise and lower

Route to prevent damage of cable. Never engage power unit with hoses disconnected

– if

so, you may to need to bleed pressure as described below.

2) Be sure to lower the unit only as deep as needed to obtain proper penetration of all six coulters.

Use depth collars provided to set desired operational depth.

3) Due to the design of the implement, it is not necessary to raise the unit during field turns.

4) Prior to road transport, always install the transport lock channel on the cylinder rod.

5) To disconnect the implement from the power unit, install the transport lock and lower the

implement until it rests on the lock. Momentarily bump the control switch upward to relieve

system pressure and disconnect the hoses. Try not to disconnect under pressure, as it will be

difficult to re-connect.

6) Periodically check the fluid level of the reservoir with the implement in the lowered position. It

should be roughly 2” from top of reservoir, with the cylinder rod in the retracted position. Unit is

filled with Mobil 424 hydraulic fluid, and should be filled with compatible fluids of viscosity index

between 100 and 400 ssu.

7) Keep couplers as free of contaminates as possible, and install rubber plugs and caps when unit

is not in use.