3 inspecting and cleaning barrier diaphragms – Honeywell SMV 3000 User Manual

Page 114

102

SMV 3000 Transmitter User’s Manual

1/99

9.3

Inspecting and Cleaning Barrier Diaphragms,

Continued

Procedure, continued

Table 27

Inspecting and Cleaning Barrier Diaphragms, Continued

Step

Action

3

Remove O-ring and clean interior of process head using soft bristle

brush and suitable solvent.

4

Inspect barrier diaphragm for any signs of deterioration or corrosion.

Look for possible residue and clean if necessary.

NOTE: If diaphragm is dented, has distorted convolutions or radial

wrinkles, performance may be affected. Contact the

Solutions Support Center for assistance.

5

Replace O-ring or teflon gasket ring.

6

Coat threads on process head bolts with anti-seize compound such

as “Neverseize” or equivalent.

7

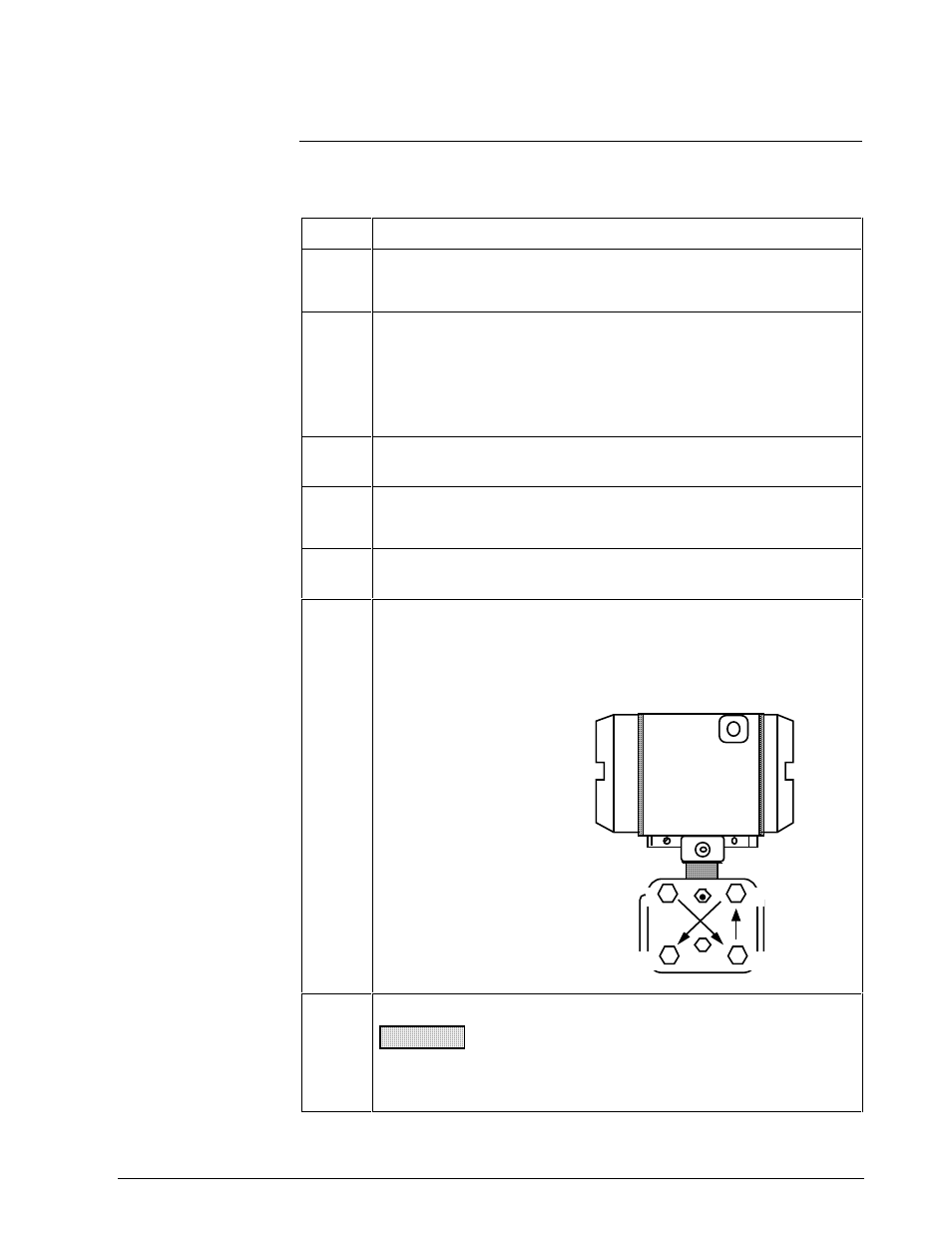

Replace process heads and bolts. Finger tighten nuts.

8

Use a torque wrench to gradually tighten nuts to torque of 40 ft-lb (54

N•m) for carbon steel process heads bolts or 35 ft-lb (47.5 N•m) for

stainless steel process head bolts in sequence shown in following

illustration. Tighten head bolts in stages of 1/3 full torque, 2/3 full

torque, and then full torque.

22519

1

2

3

4

Always tighten head bolts in

sequence shown and in these

stages:

1. 1/3 full torque

2. 2/3 full torque

3. Full torque

9

Return transmitter to service.

CAUTION Do not exceed the overload rating when placing the

transmitter back into service or during cleaning operations. See

Overpressure ratings in Section 3 of this manual.