Derating factors – Heatcraft Refrigeration Products H-ENGM0408 User Manual

Page 22

22

Holding freezer

40

80

Packaged Holding center

40

80

Cutting Room

20

30

Meat Chill Room

80

120

Boxed Banana Ripening

120

200

Vegetables and Fruit Storage

30

60

Blast Freezer

150

300

Work Areas

20

30

Unpackaged Meat Storage

30

60

Recommended Number

of Air Changes

Type of Application

Minimum

Maximum

-1,000

31.02

15.27

.0778

1.04

1.03

1.005

-500

30.47

14.97

.0763

1.02

1.02

1.002

0

29.92

14.70

.0749

1.00

1.00

1.00

500

29.38

14.43

.0735

0.98

0.98

0.995

1,000

28.86

14.28

.0719

0.96

0.96

0.998

2,000

27.82

13.67

.0697

0.93

0.93

0.985

3,000

26.81

13.27

.0671

0.90

0.90

0.98

4,000

25.84

12.70

.0647

0.86

0.875

0.975

5,000

24.89

12.23

.0623

0.83

0.85

0.969

6,000

23.98

11.78

.0600

0.80

0.82

0.960

7,000

23.09

11.34

.0578

0.77

0.79

0.955

8,000

22.22

10.92

.0556

0.74

0.76

0.946

9,000

21.38

10.50

.0535

0.71

0.73

0.939

10,000

20.58

10.11

.0515

0.69

0.71

0.93

12,000

19.03

9.35

.0477

0.64

0.66

0.91

14,000

17.57

8.63

.0439

0.59

0.61

0.88

Altitude

Absolute

Pressure

Standard

Capacity

Feet

Air

Multipliers

Above

Density

Air Direct Drive Fans

Sea

At 70ºF.

Dens.

Refrig.

Air Cooled

Level

In. Hg.

PSIA

lbs./Cu.Ft.

Ratio

Evap.

Cond. Unit

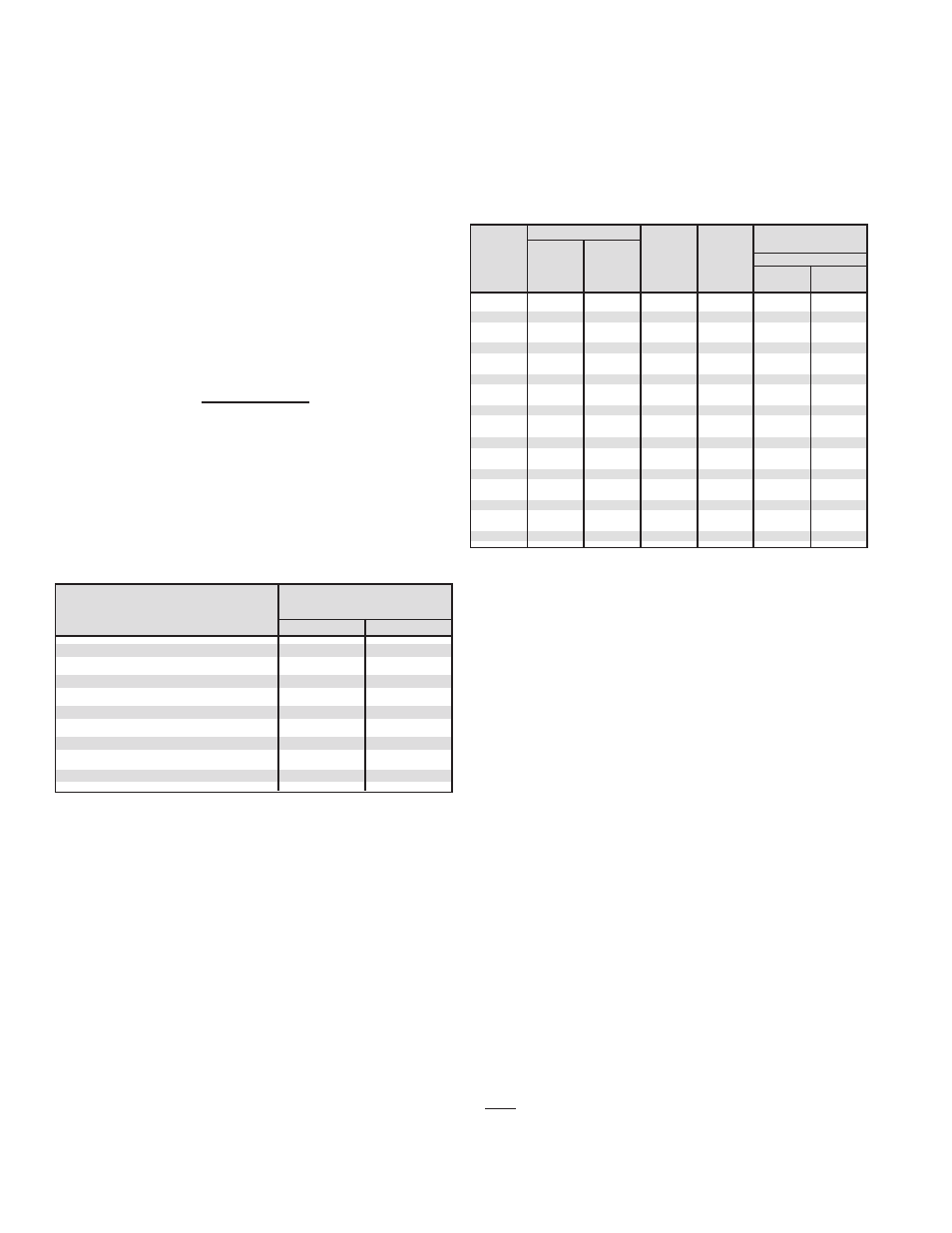

4. Type of Operation/Air Flow

Two important considerations in the selection and location of the

unit cooler are uniform air distribution and air velocities which are

compatible with the particular application.

The direction of the air and air throw should be such that there

is movement of air where there is a heat gain; this applies to the

room walls and ceiling as well as the product. The unit cooler(s)

should be arranged to direct its discharge air at any doors or

openings, if it all possible. Avoid placing the unit cooler in a

position close to a door where it may induce additional infiltration

in to the room; this can cause fan icing and a condition known as

hoar-frost. Also, avoid placing a unit in the air stream of another

unit, because defrosting difficulties can result.

For general storage coolers and holding freezers, there are not

criteria for air velocities within the room. The total supply of air

is such that approximately 40 to 80 air changes occur each hour.

This is an air conditioning term which is calculated as follows:

Air Changes = (total cfm*) x 60

internal room volume

* includes all unit coolers and auxiliary fans

This equation disregards the air motion which is induced by the

discharge air from the unit cooler. For simplicity, the gross volume

of the room is used unless the product and equipment occupy

more than 10% of the volume. Specific applications such as

cutting rooms and banana ripening rooms have desired limits. The

table below indicates the minimum and maximum quantities of air

for particular applications.

Derating Factors

A. Ambient

B. Altitude

C. Saturated Suction Temperature (S.S.T.)

D. 50 Cycle Power

In the selection of refrigeration equipment it should be noted

that the manufacturer’s equipment has ratings based on certain

criteria. Care should be taken to determine actual job conditions

and the proper derating factors should be applied. These factors

may vary by manufacturer but can be used here as rule of thumb

approximation.

A. Ambient

Condensing unit ambient is of concern as most equipment is

generally cataloged as 90º to 95ºF. ambient.

Decrease condensing unit capacity 6% for each 10ºF. increase

in operating ambient.

Increase condensing unit capacity 6% for each 10ºF. decrease

in operating ambient.

Recommended Air Changes/Hour

B. Altitude

Most manufacturers rate their equipment at sea level conditions.

An increase in altitude results in a decrease in air density. While

the fans on direct drive equipment will deliver a constant cubic

feet per minute of air regardless of density, the thinness of the

air will affect capacity performance. Belt drive equipment can be

speeded up to compensate for the decrease in air density.

C. Suction Temperature

Care should be taken in the selection of unit coolers, especially

freezer models. There is no set rating standard adopted by the

industry for the ratings criteria. The model number of a low

temperature unit cooler can be rated at -30º SST, -20º SST, -10º

SST, 0º SST, or even +10º SST. The capacity difference between

the -30º SST and the +10º SST can be as much as 15% higher for

the lower rated unit cooler. Most manufacturers provide a suction

temperature correction factor for their unit coolers and this

should be noted in equipment selections.

D. 50 Cycle Power

Since we live in a “global village,” the opportunity to quote

refrigeration equipment for export markets is one not to be

ignored. Motors that are sized for 60 cycle operation run at 83%

(50/60) speed on 50 cycles operation. Compressors produce only

5/6 of their capacity. However, while fans are only running 83%

speed, there is also a decrease in static pressure through the

condenser or unit cooler coil and performance does not suffer the

full 17% penalty. If it has been verified by the manufacturer that

their equipment can be run on 50 cycle power then the following

derating factors can be applied:

A.

Unit coolers and air-cooled condensers (Capacity x 0.92)

B.

Air-cooled condensing units (capacity x .85)

System capacity (unit cooler and air-cooled condensing unit) can

be derated by 0.88

To select refrigeration equipment after the load has been

determined, divide the BTUH required by (0.88):

BTUH = Conversion to select 60 cycle

0.88 equipment for 50 cycle load

This provides for larger equipment necessary to compensate for

50 cycle derating factor.

Effects of Altitude on Air Cooled Equipment