Appendix - tables, Table 3 allowance for sun effect – Heatcraft Refrigeration Products H-ENGM0408 User Manual

Page 13

13

Insulation

Insul. K Factor

6”

8”

10”

12”

Air

4.65

6.94

6.65

6.50

6.40

Vermiculite

.47

2.73

2.67

2.64

2.62

Sawdust

.45

2.70

2.65

2.62

2.60

Cork

.38

2.62

2.57

2.55

2.53

Rock Wool

.30

2.52

2.49

2.47

2.45

Mac. Paper

.28

2.50

2.46

2.45

2.43

Styrofoam

.24

2.45

2.42

2.40

2.40

Polyurethane

.16

2.36

2.33

2.33

2.32

Type of

East

South

West

Flat

Surface

Wall

Wall

Wall

Roof

Dark Colored Surfaces,

Such as:

Slate Roofing

8

5

8

20

Tar Roofing

Black Paints

Light Colored Surface,

Such as:

White Stone

4

2

4

9

Light Colored Cement

White Paint

Medium Colored Surface,

Such as:

Unpainted Wood

Brick

6

4

6

15

Red Tile

Dark Cement

Red, Gray or Green Paint

1

4

5.10 204 230 255 281 306 332 357 383 408 434 459 485 510 536 561 587

612

2

8

3.40 136 153 170 187 204 221 238 255 272 289 306 323 340 357 374 391

408

4

3

2

12.6 1.80

72

81

90

99

108 117 126 135 144 153 162 171 180 189 198 207

216

5

4

2

16.4 1.44

58

65

72

79

87

94 101 108 115 122 130 137 144 151 159 166

173

6

5

3

19.6 1.20

48

54

60

66

72

78

84

90

96

102 108 114 120 126 132 138

144

8

6

4

3

25

0.90

36

41

45

50

54

59

63

68

72

77

81

86

90

95

99 104

108

10

8

4

33

0.72

29

32

36

40

43

47

50

54

58

61

65

68

72

76

79

83

86

10

6

38.7 0.60

24

27

30

33

36

39

42

45

48

51

54

57

60

63

66

69

72

6

50

0.48

19

22

24

26

29

31

34

36

38

41

43

46

48

51

53

55

58

Single window glass

. 9

27 1080 1215 1350 1490 1620 1760 1890 2030 2160 2290 2440 2560 2700 2840 2970 3100 3240

Double Window Glass

2.2

11

440 495 550 610 660 715 770 825 880 936 990 1050 1100 1160 1210 1270 1320

Triple Window Glass

3.4

7

280 315 350 390 420 454 490 525 560 595 630 665 700 740 770 810

840

6” Concrete Floor

4.8

5

200 225 250 275 300 325 350 375 400 425 450 475 500 525 550 575

600

Insulation (Inches)

Heat Load (BTU Per 24 Hours Per One Square Foot of Outside Surface)

Cork

Glass

Urethane

or

Fiber or

Urethane

(Foamed Temperature Reduction in ºF.

Mineral

Poly-

(Sprayed)

in

R (Outside Air Temperature Minus Room Temperature)

Wool

Styrene

Place)

k = .30

k = .26

k = .16

k = .12

1

40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120

Appendix - Tables

Note: Above insulation “K” Factors [Thermal Conductivity, BTU

per (hour) (square foot) (ºF. per inch of thickness)] and heat

gain factors for Cork and Window Glasses are extracted and

Insulation Values

“K” Factor - Insulating Value of any material is rated by its thermal conductivity

“U” Factor

- Overall coefficient of heat transfer, BTU per hour/per square foot/per degree F.

“R” Factor

- Thermal resistances

“X” = Inches of Insulation

K = UX = X/R

U = K/X = 1/R

R = 1/U = X/K

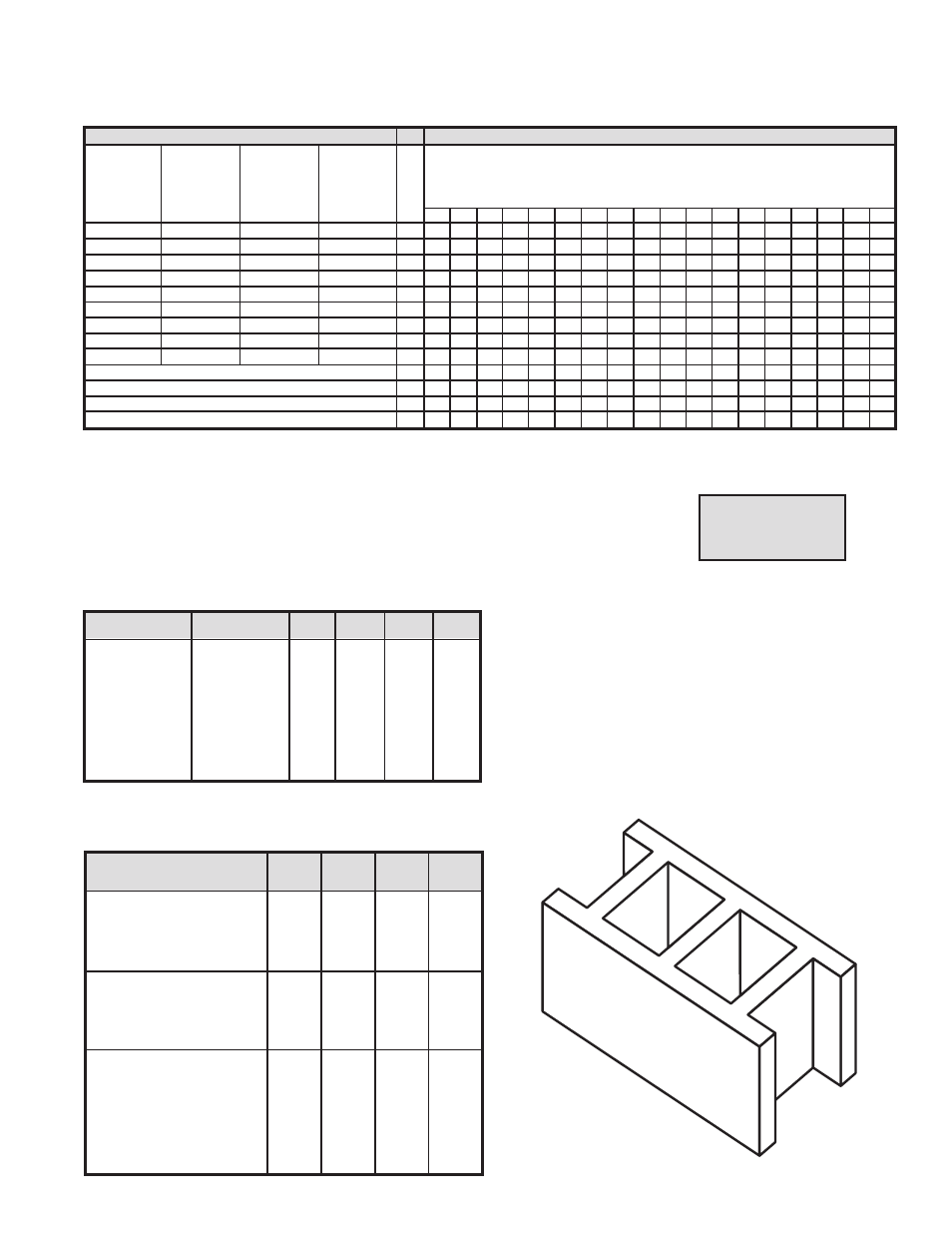

Table 2

Effective K Factor in Block Thickness of Insulation

Note: If blocks have 3 holes, add .75 to all of the values shown. The

above data is being shown for reference purpose only - this is a very

inefficient method of construction/insulation due to:

1. Concrete webs are dominant factor in calculating insulating effect.

2. Filling techniques may leave blocks improperly filled.

3. No vapor seal present - moisture infiltration decreases insulation

effect.

4. If used for freezers, moisture will freeze inside block and break

out the surface of the block.

5. Blocks are highly subject to setting cracks- more infiltration.

Table 3

Allowance for Sun Effect

(Fahrenheit degrees to be added to the normal temperature difference for heat leakage

calculations to compensate for sun effect- not to be used for air conditioning design.)

reprinted by permission from ASHRAE 1972 HANDBOOK OF

FUNDAMENTALS.

Table 1

Wall Heat Loads