Heatcraft Refrigeration Products H-ENGM0408 User Manual

Page 19

19

Banana Ripening Room

Banana hands or cluster shipped greens in fiberboard cartons,

10” x 16” x 22”, holding 42 lb. net (47 lbs. gross weight) with

864 boxes (3,288) lbs, net in a carload lot. Temperature held 56 to

58ºF.

Ripening facility consists of 5 or more air tight rooms to permit a

completely weekly turn-over (1/2 carload room, measuring 30’ x

6’ x 22’H outside, holds 432 boxes packed, 24 boxes each on 18

pallets stacked 3 high by 6 long). Ripening process started with

ethylene gas and ripening schedules maintained by control of

room temperatures.

Heating is provided to bring the load up to temperature before

ripening process is initiated. 12 to 20 Kw per carload. (Electric

heater sheath temperature not over 600ºF. in dead still air).

Evaporators are selected at a T.D. of 15ºF., or less, with evaporator

temperature controlled at no less than 40ºF. Approximately 12.5

cfm at 2/3” to 3/4” static per 41 lb. box of bananas.

Pull down load for 1ºF./hr. pull down rate based on maximum heat

of respiration of 2.5 BTU/lb. and 0.8 sp. ht. for bananas and 0.4 for

fiberboard boxing, plus minimal wall losses etc., 80 to 85 BTU/hr./

box of bananas. Holding load approximately 44 BTU/hr./box.

Extracted from ASHRAE 1974 APPLICATION HANDBOOK.

Loading: 5.3 lbs./Cu. Ft. of box, 11.28 lbs. net per pallet

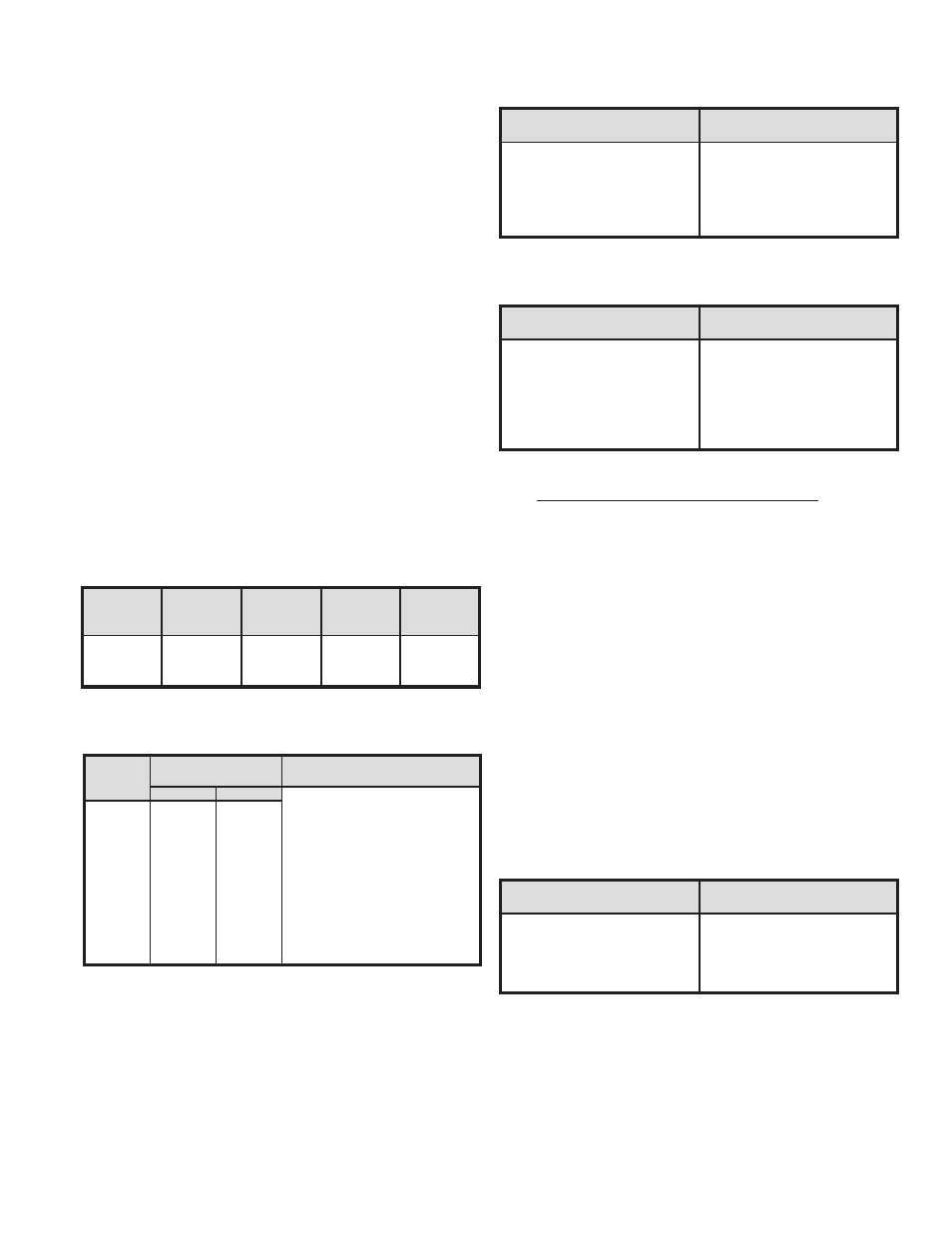

Number

Evaporator

Approx.

Elect.

Room

Boxes

BTU Per

CFM Air

Heat

Size

Prod.

10º TD

Volume

Input

1/2 Car

432

36000

6000

6Kw

1 Car

864

72000

12000

12Kw

2 Car

1728

144000

24000

24Kw

Table 16

Banana Rooms – Refrigeration Requirements

Floor

Approx. 65% R.H.

SQ FT

Room Temp.

55ºF.

50ºF.

100

93

105

200

88

99

300

85

95

400

81

90

500

78

87

600

75

85

700

72

81

800

69

78

900

67

75

1000

65

73

1200

62

69

Room Loads based on continuous

operation and includes allowance

for average number of personnel,

processing equipment, etc., with

glass panel in one wall and walls

and ceiling insulated with 3” of

styrene with box located in air

conditioned area. Evaporator

should be low outlet velocity type

to avoid drafts and should be

selected for continuous operation

and not less than 30ºF. evap. temp.

Table 17

Meat Cutting/Prep Room Load

(BTU/HR/SQ FT of floor area)

Table 18

Rapid load selection for back bars

(Based on 2” glass fiber or equivalent insulation and 50ºF., T.D.)

Back Bar

BTU/Hour Load Based on

Length in feet

16 Hour Compressor Operation

6 Feet

1,060

8 Feet

1,416

10 Feet

1,770

12 Feet

2,120

15 Feet

2,650

20 Feet

3,540

Table 19

Refrigeration requirements for hardening ice cream

Overrun

Hardening Load, BTU

Percent

per Gal. Ice Cream

60

532

70

500

80

470

90

447

100

425

110

405

120

386

Percentage overrun =

100 x Wt. per gal. of mix - Wt. per gal. of ice cream

Wt. per gal. of ice cream

Ice cream assumed at 25ºF., and 30% frozen, entering

hardening room.

To retain a smooth texture in hardened ice cream, it

is necessary to freeze the remaining water content

rapidly. With forced air circulation, time to harden

will be about 10 hours with room maintained at

-20. Hardening rooms are usually sized to allow for

minimum of 3 times the daily peak production and for

a stock of all flavors with the size based on 10 gallons

per sq. ft. stacked solid 6 ft. high, including space for

isles.

Reprinted by permission from

ASHRAE 1974 APPLICATION HANDBOOK

Table 20

Glass Door Loads

Box

BTU per

Temperature

Door

+35

1060

+30

960

0

1730

-10

1730

-20

1730

* Adjusted for 16-18 hour run time. Multiply number of doors

times door load above and add to box load.