Example: -20ºf ice cream hardening freezer – Heatcraft Refrigeration Products H-ENGM0408 User Manual

Page 10

10

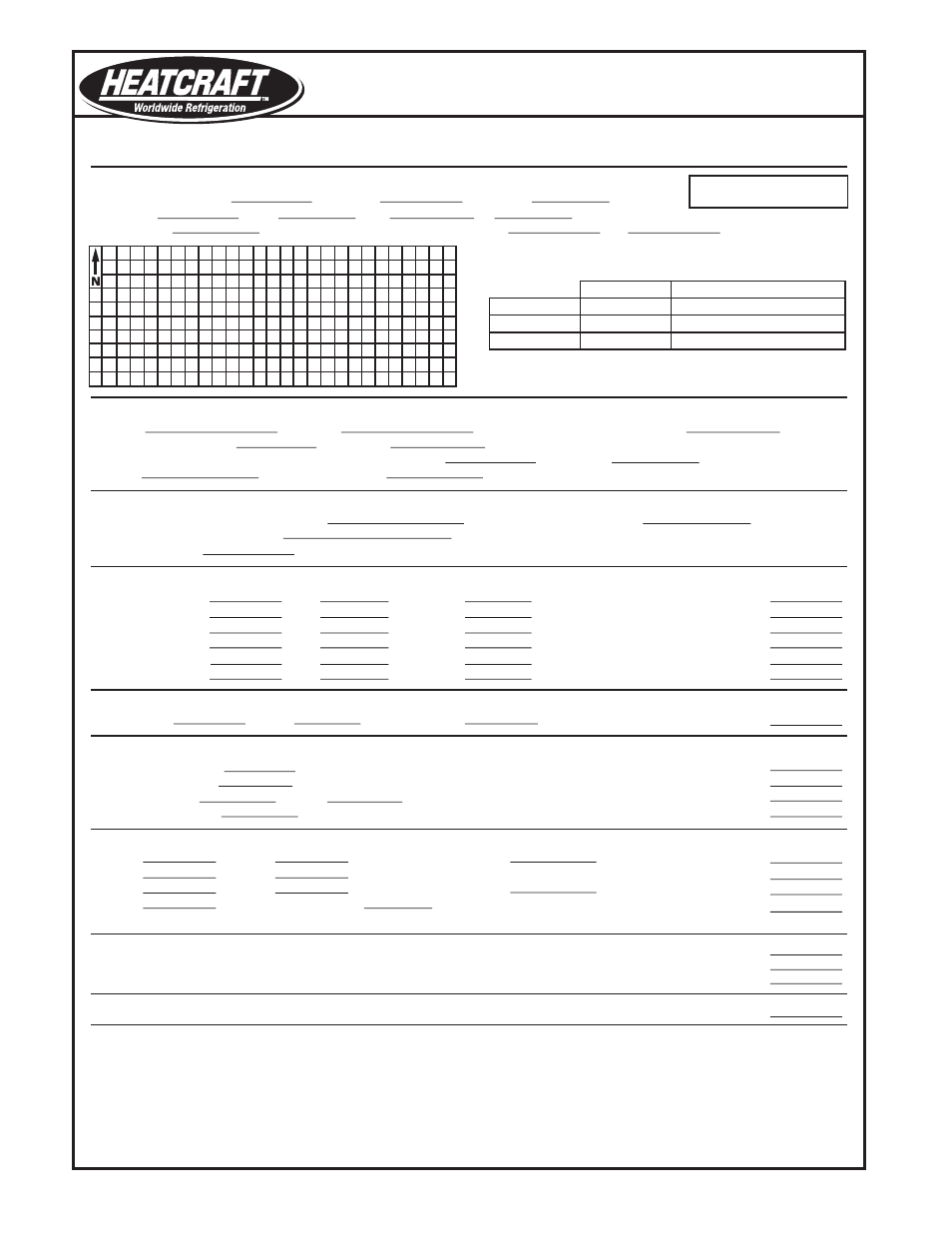

Refrigeration Load Estimate Form

(for rooms below 32ºF) Bulletin Below32-05

Estimate for:

Basis for Estimate

Room Dimensions: Width

ft. x Length

ft. x Height

ft.

Volume: (L)

x (W)

x (H) = cu. ft.

Ambient Temp ºF. (Corrected for sun load) — Room Temp. ºF. = ºF. T.D.

Product Load

(a) lbs./day of to be reduced from entering temp. of ºF.

to freezing point of ºF. (Table 7) = ºF. Initial temp. drop

and then reduced from freezing point to storage Temp. of ºF. = (Table 7) ºF. Final temp. drop.

(b) gallons of ice cream @ overrun

Miscellaneous

Motors (including all blower motors) HP Ground Temp. (Table 21)

Lights (assume 1 watt/sq.ft.) Watts

No. of People

2. Air Change Load

Volume: cu. ft. x Factor (Table 5) x Factor (Table 6)

=

3. Additional Loads

Electrical Motors: HP x 75000 BTU/HP/24 hr.

=

Electrical Lights: Watts x 82

=

People Load: People x BTU/24 hrs. (Table 12)

=

Glass Door Load: Doors x 31200 BTU/Door/24 hr.

=

4. Product Load: (Table 7) (Product Load Figured @ 24 hr. Pulldown*)

(a) lbs./day x Spec. Heat above freezing x ºF. Intial Temp. Drop

=

lbs./day x Latent Heat Fusion

=

lbs./day x Spec. Heat below freezing x ºF. Intial Temp. Drop

=

(b) gallons of ice cream/day x BTU/gal (Table 19)

=

*For product pulldown time other than 24 hrs. figure 24 hr. load x (24/Pulldown Time)

Divide by No. of Operating Hrs. (18) to obtain BTUH Cooling Requirement

Equipment Selection

Condensing Unit

Unit Cooler

System Capacity

Qty. Model No.

Qty. Model No.

BTU/hr.

Total Refrigeration Load (1+2+3+4+5) BTU/24 hrs.

Add 10% Safety Factor

Total with Safety/Factor BTU/24 hrs.

1. Transmission Loads

Ceiling: (L)

x (W)

x Heat Load

(Table 1)

=

North Wall: (L)

x (W)

x Heat Load

(Table 1)

=

South Wall: (L)

x (W)

x Heat Load

(Table 1)

=

East Wall: (L)

x (W)

x Heat Load

(Table 1)

=

West Wall: (L)

x (W)

x Heat Load

(Table 1)

=

Floor: (L)

x (W)

x Heat Load

(Table 1)

=

Estimate by:

Date:

Insulation

Inches

Ceiling

Walls

Floor

Type

Note: Tables can be found in

Engineering Manual, H-ENG-2

2175 West Park Place Blvd. • Stone Mountain, GA 30087 • 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

(H)

(H)

(H)

Example: -20ºF Ice Cream Hardening Freezer

12 14 8

14 12 8 1344

85 -20 105

4 Foamed In place Ure

4 Foamed In place Ure

4 Foamed In place Ure

— —

—

— —

— —

100 100%

0.2 60

168

0

14 12 76 12768

14 8 76 8512

14 8 76 8512

12 8 76 7296

12 8 76 7296

14 12 58 9744

1344 12 3.49 56287

0.2 15000

168 13776

0 —

—

10 —

— — —

— — —

— — —

100 425

X 2.4 (10 hr. Pull down)* 102000

241191

24119

265310

14739

(W)

(W)

(H)