17. common gmaw (mig) shielding gases – Hobart Welding Products HANDLER 125 User Manual

Page 42

OM-947 Page 38

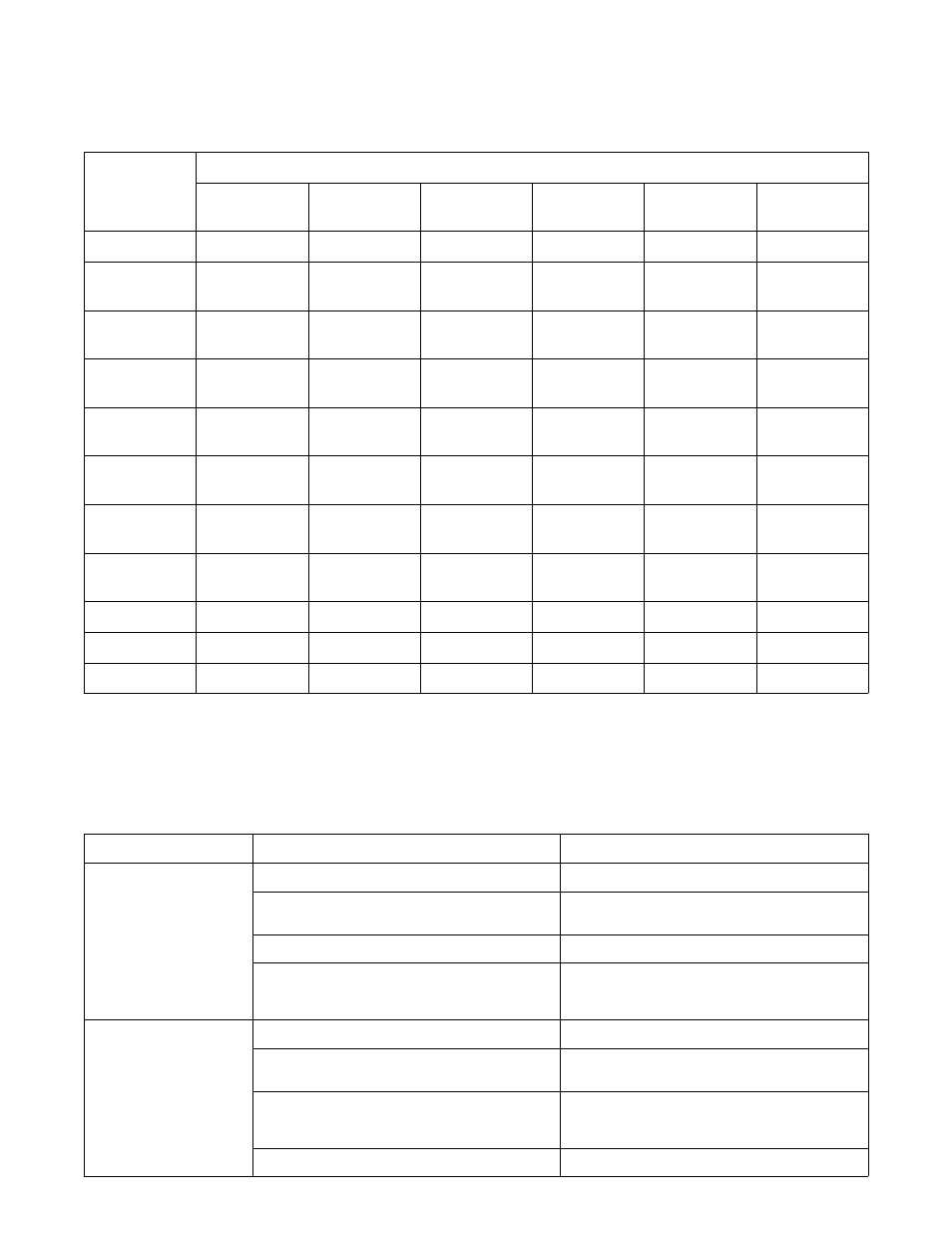

9-17. Common GMAW (MIG) Shielding Gases

This is a general chart for common gases and where they are used. Many different combinations (mixtures) of

shielding gases have been developed over the years. The most commonly used shielding gases are listed in the

following table.

Application

Gas

Spray Arc Steel

Short Circuiting

Steel

Spray Arc

Stainless Steel

Short Circuiting

Stainless Steel

Spray Arc

Aluminum

Short Circuiting

Aluminum

Argon

All Positions

5

All Positions

Argon + 1% O

2

Flat & Horizontal

5

Fillet

Flat & Horizontal

5

Fillet

Argon + 2% O

2

Flat & Horizontal

5

Fillet

Flat & Horizontal

5

Fillet

Argon + 5% O

2

Flat & Horizontal

5

Fillet

Argon + 8% CO

2

Flat & Horizontal

5

Fillet

All Positions

Argon + 25%

CO

2

Flat & Horizontal

1

Fillet

All Positions

All Positions

3

Argon + 50%

CO

2

All Positions

CO

2

Flat & Horizontal

1

Fillet

All Positions

Helium

All Positions

2

Argon + Helium

All Positions

2

Tri-Mix

4

All Positions

1

Globular Transfer

2

Heavy Thicknesses

3

Single Pass Welding Only

4

90% HE + 7-1/2% AR + 2-1/2% CO

2

5

Also for GMAW-P, All Positions

9-18. Troubleshooting Guide For Semiautomatic Welding Equipment

Problem

Probable Cause

Remedy

Wire feed motor operates, but

wire does not feed.

Too little pressure on wire feed rolls.

Increase pressure setting on wire feed rolls.

Incorrect wire feed rolls.

Check size stamped on wire feed rolls, replace to match

wire size and type if necessary.

Wire spool brake pressure too high.

Decrease brake pressure on wire spool.

Restriction in the gun and/or assembly.

Check and replace cable, gun, and contact tip if

damaged. Check size of contact tip and cable liner,

replace if necessary.

Wire curling up in front of the

wire feed rolls (bird nesting).

Too much pressure on wire feed rolls.

Decrease pressure setting on wire feed rolls.

Incorrect cable liner or gun contact tip size.

Check size of contact tip and check cable liner length

and diameter, replace if necessary.

Gun end not inserted into drive housing properly.

Loosen gun securing bolt in drive housing and push gun

end into housing just enough so it does not touch wire

feed rolls.

Dirty or damaged (kinked) liner.

Replace liner.