5. conditions that affect weld bead shape – Hobart Welding Products HANDLER 125 User Manual

Page 37

OM-947 Page 33

9-5.

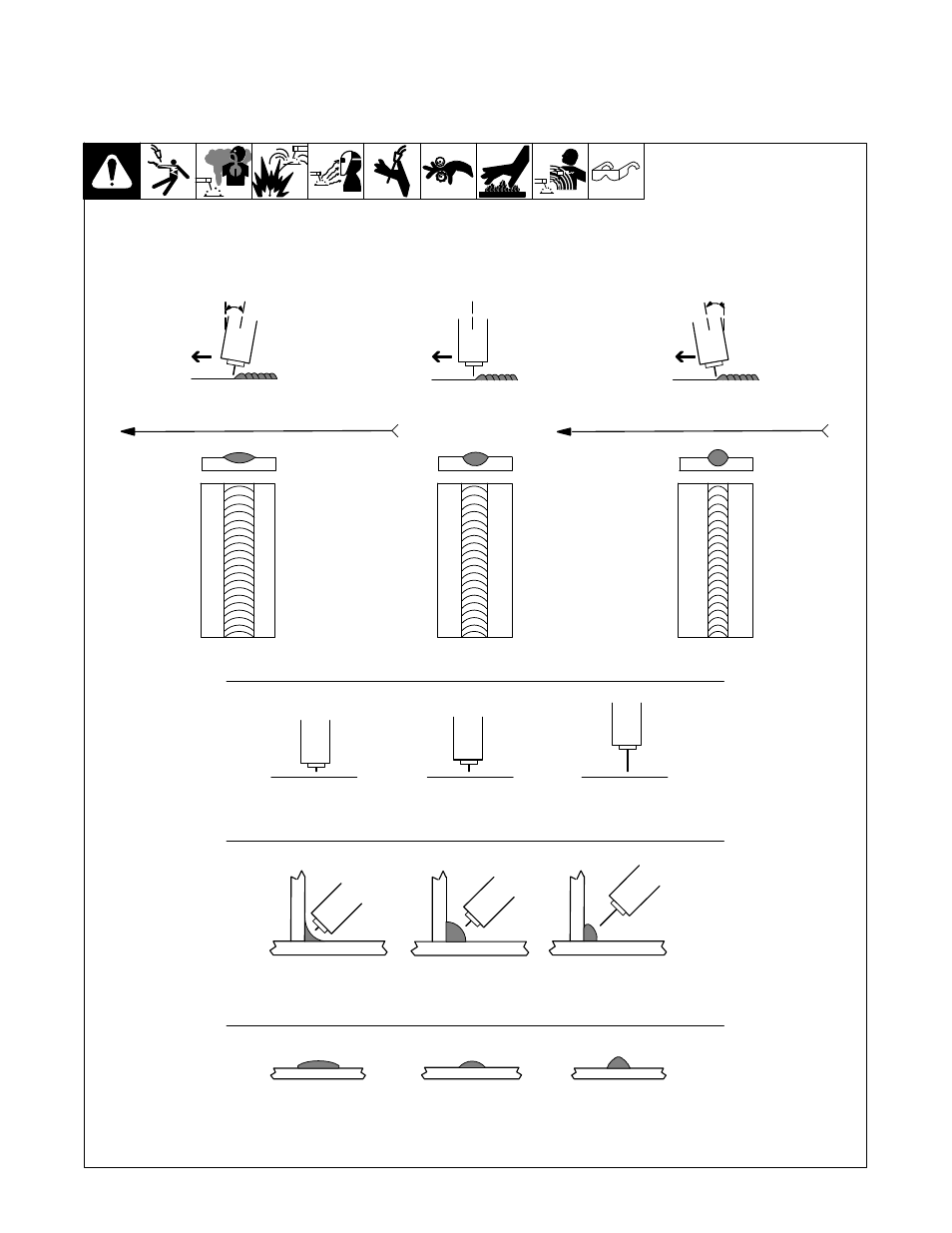

Conditions That Affect Weld Bead Shape

.

Weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base metal, wire feed speed

(weld current), and voltage.

Slow

FILLET WELD ELECTODE EXTENSIONS (STICKOUT)

ELECTRODE EXTENSIONS (STICKOUT)

GUN ANGLES AND WELD BEAD PROFILES

10

°

10

°

GUN TRAVEL SPEED

S-0634

Push

Perpendicular

Drag or Pull

Short

Normal

Long

Short

Normal

Long

Normal

Fast

Electrode directed

ahead of bead

Electrode pointed

back into bead

Direction Of Welding

.

The Drag or Pull technique is generally recommended when welding with flux-cored tubular wire.

See also other documents in the category Hobart Welding Products Tools:

- XTP (16 pages)

- IRONMAN M-10 (56 pages)

- HANDLER 140 217 694E (48 pages)

- OM-1594 (68 pages)

- DP-3035 (28 pages)

- 250A (32 pages)

- 175 (52 pages)

- OM-947 (48 pages)

- CHAMP 2060 (60 pages)

- 120 (48 pages)

- OM-494 (76 pages)

- 302 (40 pages)

- DP 3035-10 (32 pages)

- CHAMPION 4500 210 597J (52 pages)

- OLYMPIC R-115 (36 pages)

- HOOD XVX (20 pages)

- HANDLER 180 (52 pages)

- STICKMATE OM-950 (40 pages)

- 3035-20 (32 pages)

- H-9A Gun (24 pages)

- HANDLER 210 (52 pages)

- OM-948 (24 pages)

- 187 (52 pages)

- AIRFORCE 375 OM-2210 (32 pages)

- ARCSTAR OM-487 (60 pages)

- 300 AC (32 pages)

- Stickmate 205 AC (2 pages)

- AIRFORCE HP-25 TORCH (36 pages)

- 1435 (60 pages)

- AIRFORCE 250A (32 pages)

- 000 OM-945 194 047U (64 pages)

- 000 OM-945 (68 pages)

- CHAMPION OM-493 (56 pages)

- CHAMPION ELITE OM-240 438E (64 pages)

- AIRFORCE OM-230 455D (36 pages)

- SPOOL GUN DP 3035-20 (32 pages)

- OLYMPIC S-62 (36 pages)

- SPOOL GUN 3035-20 (2 pages)

- STICKMATE OM-949 (36 pages)

- HANDLER 210 OM-227 978B (52 pages)

- AIRFORCE OM-928 (32 pages)

- AIRFORCE 700I (40 pages)

- IRONMAN 230 (56 pages)

- HANDLER 210 MVP (56 pages)

- ARCSTAR 280 NT (52 pages)