4. changing drive roll or wire inlet guide – Hobart Welding Products HANDLER 125 User Manual

Page 27

.

A complete Parts List is available at www.HobartWelders.com

OM-947 Page 23

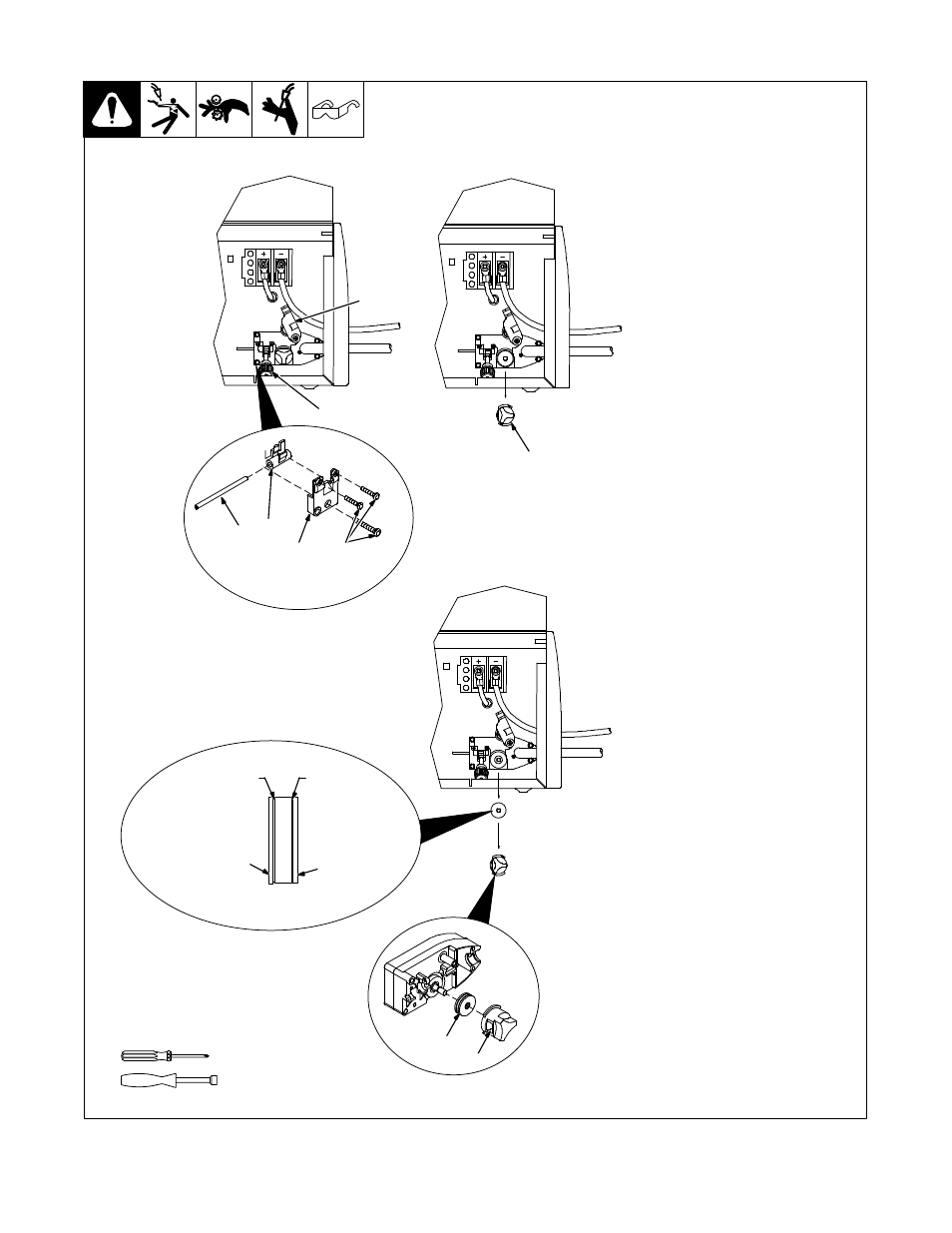

7-4. Changing Drive Roll Or Wire Inlet Guide

1

Pressure Adjustment Knob

2

Pressure Assembly

Pivot pressure adjustment knob

down, and lift pressure assembly

up.

3

Pivot Tube Plate

4

Securing Screws

5

Pressure Arm Pivot Tube

6

Inlet Wire Guide

Remove screws and pivot tube

plate. Lift out pressure arm pivot

tube, and slide inlet wire guide out of

tube.

Slide replacement wire guide into

tube, and place tube back into drive

assembly. Be sure tip of wire guide

is as close to drive roll as possible

without touching.

Reinstall plate and tighten screws.

7

Retaining Knob

Rotate counterclockwise and

remove knob.

8

Drive Roll

The drive roll consists of two

different sized grooves. Each side

is stamped with the proper size.

Select the groove that matches the

wire size on the wire spool. Install

drive roll onto motor shaft so that

correct groove size stamp faces out

away from drive housing.

9

Retaining Knob Opening

Install retaining knob by placing

opening over drive roll (opening

faces rear of unit). Rotate retaining

knob clockwise to secure drive roll.

Position wire into outer groove of

drive roll (see Section 5-9).

Tools Needed:

Ref. 802 444-B / 803 442-A

.024 Groove

.030/.035

VK

Groove

Stamped .024

Stamped .030/.035

1

3

4

5

6

2

7

5/16 in.

8

9