0 preoperational procedures – Harrington Hoists NER2 User Manual

Page 7

7

3.0 Preoperational Procedures

3.1 Gear

Box

3.1.1

The gearbox is filled with the correct amount of oil at the time of shipment. The oil level must be verified

prior to operation. The ER2 and NER2 hoists have different checking procedures. Refer to

Section 6.3

of the ER2OM for specific checking procedures. Use the 050L Capacity Code to determine the correct

“Check Distance” for the ER2 Large Capacity hoist.

3.1.2 Refer

to

Section 6.3

of the ER2OM

when replacing the gear oil. Use the 050L Capacity Code to

determine the correct amount of gear oil.

3.1.3

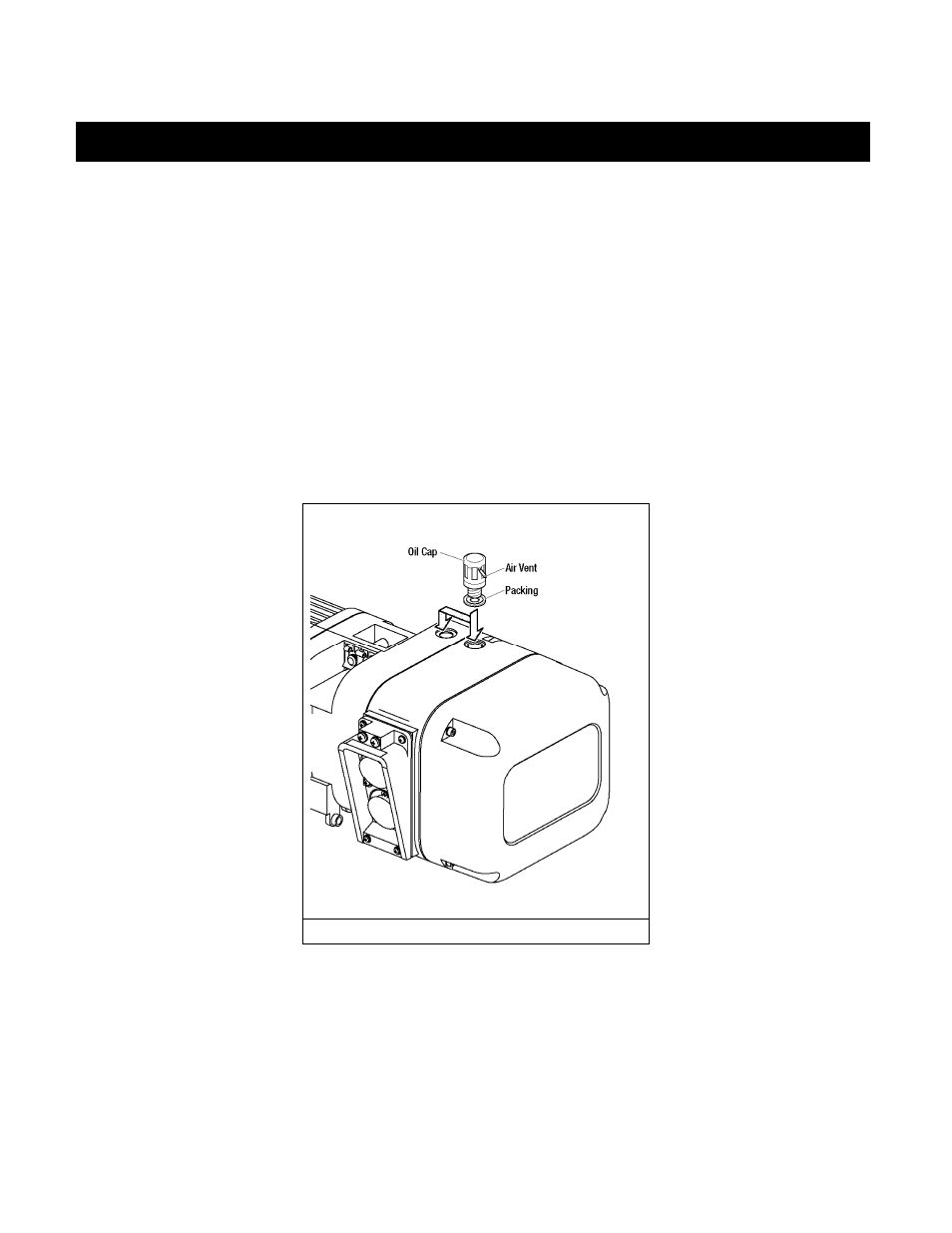

All ER2, mechanical load brake installed, hoists are shipped with a separate air vented oil cap. This

vented oil cap must be installed prior to use. To install, remove an existing oil cap and replace with the

vented oil cap (refer to

Figure 3-1)

.

3.1.4

There are two oil fill holes located in the top of the gear case on the ER2 hoist. For ER2 coupled to

MR2 trolley, there are some flange widths that make it necessary to relocate the oil cap assembly to the

other oil fill hole. This will prevent interference with trolley side plate. Refer to

Figure 3-1

.

Figure 3-1

Vented Oil Cap Installation