Eagle Electronics FISHEASY 240 User Manual

Page 26

20

For example, some (but not all) manufacturers use a layer of fiberglass,

then a core of balsa wood, finishing with an outer layer of fiberglass.

Removing the inner layer of fiberglass and the balsa wood core exposes

the outer layer of fiberglass. The transducer can then be epoxied di-

rectly to the outer layer of fiberglass. After the epoxy cures for 24

hours, fill the remaining space with polyester resin. When the job is

finished, the hull is watertight and structurally sound. Remember, the

sonar signal must pass through solid fiberglass. Any air bubbles in the

fiberglass or the epoxy will reduce or eliminate the sonar signals.

Testing Determines Best Location

Ideally, the shoot-thru transducer should be installed as close to the

transom as possible, close to the centerline. This will give you the best

performance during high speed maneuvers.

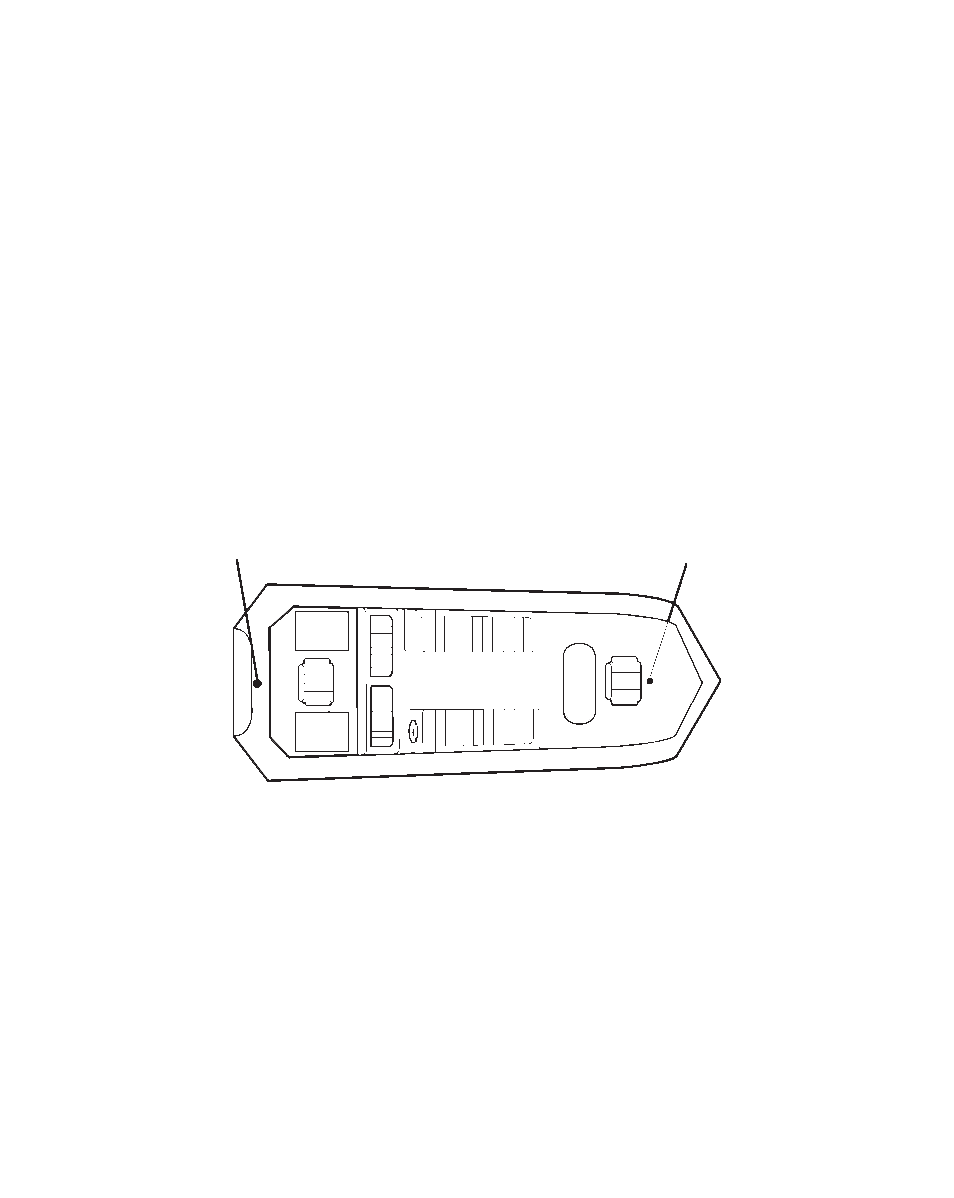

Shoot-thru-hull transducer locations for

high speed or trolling speed operation.

1. Anchor the boat in about 30 feet of water. Add a little water to the sump

of the boat. Plug the transducer into the sonar unit, turn it on, then hold

the transducer over the side of the boat in the water. Adjust the sensitiv-

ity and range controls until a second bottom echo is seen on the display.

(You'll need to turn off Auto Sensitivity, Auto Depth Range and ASP

.

Try a range setting that is two to three times the water depth. The harder

Transducer location (trolling speed)

Transducer location (high speed)