Thermal considerations, Thermal testing setup, Thermal derating – Delta Electronics H48SR User Manual

Page 11

DS_H48SR1R880_06272006

11

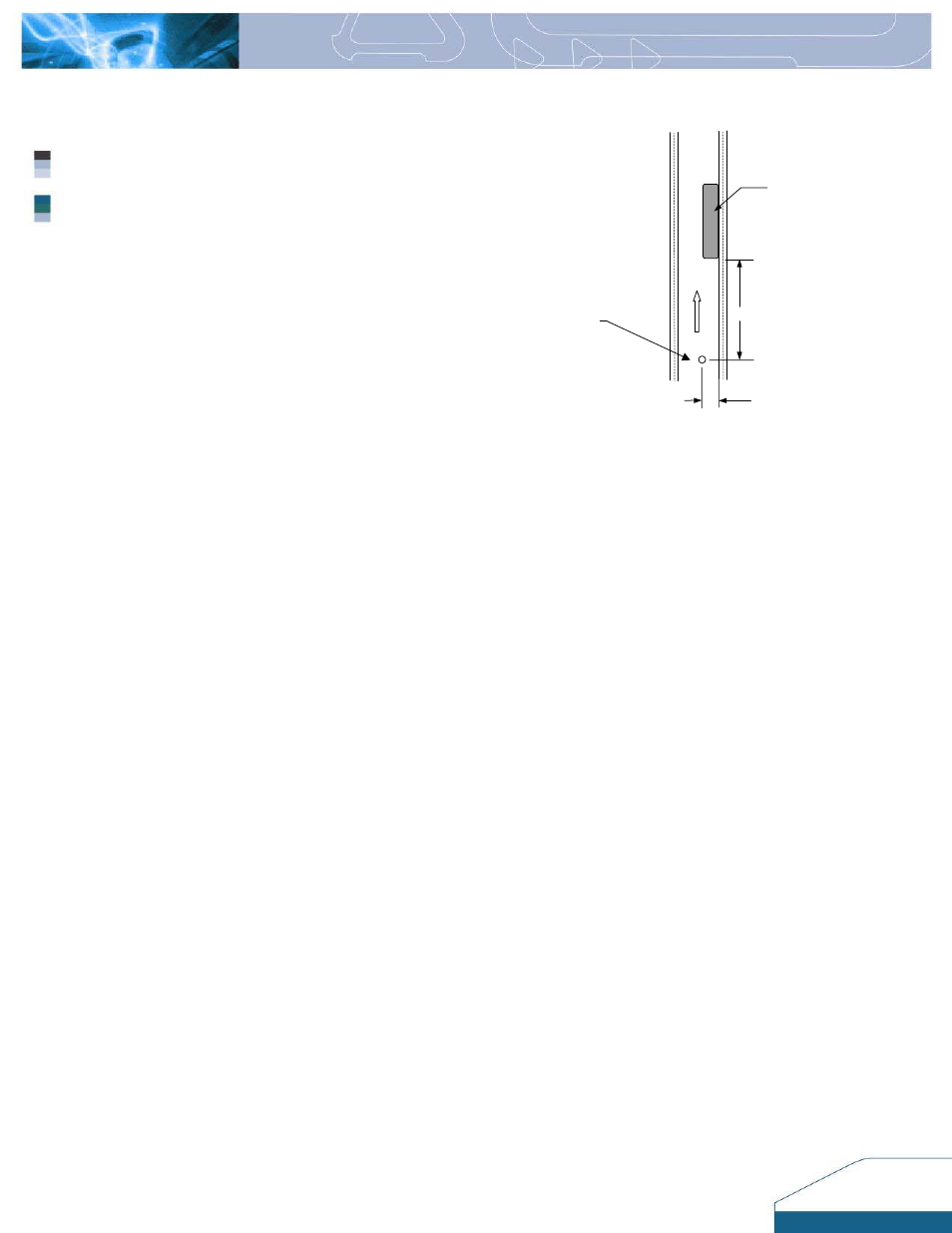

Note: Wind Tunnel Test Setup Figure Dimensions are in millimeters and (Inches)

12.7 (0.5”)

MODULE

AIR FLOW

50.8 (2.0”)

FACING PWB

PWB

AIR VELOCITY

AND AMBIENT

TEMPERATURE

MEASURED BELOW

THE MODULE

Figure 27:

Wind Tunnel Test Setup

THERMAL CONSIDERATIONS

Thermal management is an important part of the

system design. To ensure proper, reliable operation,

sufficient cooling of the power module is needed over

the entire temperature range of the module. Convection

cooling is usually the dominant mode of heat transfer.

Hence, the choice of equipment to characterize the

thermal performance of the power module is a wind

tunnel.

Thermal Testing Setup

Delta’s DC/DC power modules are characterized in

heated vertical wind tunnels that simulate the thermal

environments encountered in most electronics

equipment. This type of equipment commonly uses

vertically mounted circuit cards in cabinet racks in which

the power modules are mounted.

The following figure shows the wind tunnel

characterization setup. The power module is mounted

on a test PWB and is vertically positioned within the

wind tunnel. The space between the neighboring PWB

and the top of the power module is constantly kept at

6.35mm (0.25’’).

Thermal Derating

Heat can be removed by increasing airflow over the

module. The module’s maximum device temperature is

115 ℃ and the measured location is illustrated in Figure

18. To enhance system reliability, the power module

should always be operated below the maximum

operating temperature. If the temperature exceeds the

maximum module temperature, reliability of the unit

may be affected.