Delta Electronics Function Card DVP-EH User Manual

Page 2

Applicable

Model

Model

Name

Outline

Function Explanation

EP EH

There are 2 digital output

points that provided by

F2OT card. Output type is

transistor and user can

driver output points by using

M1112 and M1113.

AY0 AC0 AY1

AC1

.

M1112

M1113

DVP-F2OT

Item

Current spec. Voltage spec. Max. load Response time

Output

spec.

0.3A/1point 30VDC 9W/1point

Off→On 20us

On→Off 30us

○

○

DVP-F6VR

There are two built-in analog knob VR0 and

VR1 in EP/EH MPU. You can expand analog

input equip to VR2~VR7 by using this VR card.

Refer to API85 VRRD and API86 VRSC in

application manual (programming) for detail.

VR2

VR3

VR4

VR5

VR6

VR7

○

○

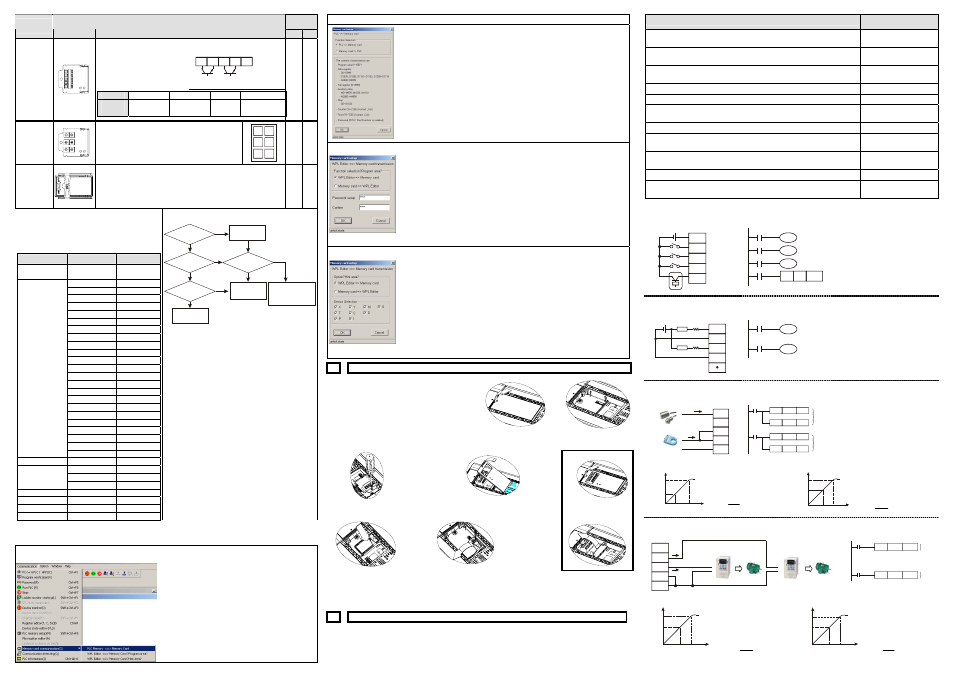

DVP-256FM

256FM is a data backup memory card. There is a switch on it

and PLC will check the state of this switch when PLC is power

on. If this switch is Off, memory card will be invalid. And it is

invalid to change the switch when PLC is power on. All

memory data read/write action will be valid when switch is On.

╳

○

It will check password during date copy. If

there is password in memory card, it will also be

copied to PLC and PLC will be locked. See

flowchart at the right side.

There are several sections for copy data in

memory to PLC as shown in the following.

Data block

Setting range

Default

Program area

15872 Steps

All are NOP

instruction

Data register

D0~D999

K0

D1035,

D1038

K0

D1101

K0

D1102

K1600

D1103

K2000

D1200

K500

D1201

K999

D1202

K2000

D1203

K4095

D1204~D1207

K-1

D1208

K100

D1209

K199

D1210

K220

D1211

K234

D1212

K235

D1213

K255

D1214

K500

D1215

K899

D1216

K200

D1217

K999

D1218

K2000

D1219

K9999

D2000~D9999

K0

File register

0~4999

K0

M0~M999 Off

M1035, M1101 Off

Auxiliary relay

M2000~M4095 Off

Step point

S0~S1023

Off

Timer T0~T255

K0

Counter C0~C255

K0

Password 4

words Off

OFF

ON

The flowchart for uploading data to PLC

when installing on MPU and power is on:

check switch

memory card

is invalid

check PLC

password

no password

lock with password

password is

correct or not?

correct

incorrect

check if there is

password in

memory card

no password

lock with

password

copy data in

memory card

to PLC

memory card

won be active

copy password in

memory card to PLC

to be as PLC

password

Therefore, 256FM card can be used for data

backup and PLC copy. It can write PLC major

data block (according to left table) into memory

card according to following two steps. Step 1:

finish setting program parameters, file register

parameters or other relative latched parameters

by using WPLSoft or HPP02. Step 2: choose

communication -> communication for memory

card in WPLSoft software. You can insert this

memory card into other EH MPU to finish PLC

copy function quickly. After this PLC MPU is

power on, the data in memory card will upload to

PLC relative data area. (only for DVP-EH MPU

(32 points and more))

Those data in 256FM card can be read/wrote

by using WPLSoft or HPP02 but there is limit for

editing or read/write data. For HPP02, it can only

read/write the DATA in program area and file

register area.

When inserting memory card in PLC, you can read/write data in memory card by using WPL. The

operations are in the following: (please confirm that switch on memory card is On before PLC is power

on. And also confirm that connection is successful to read/write data in memory card.

Using WPLSoft to select communication ->

communication for memory card

There are three modes:

PLC memory memory card

You can copy data in memory card to PLC or copy

data in PLC to memory card.

WPL working area memory card [program]

It can copy program that edited by WPL to memory

card or copy PLC program in memory card to WPL

working area.

WPL working area memory card [commentary]

It can copy commentary in WPL to memory card or

read commentary from memory card (commentary

in memory card can be only loaded in WPL working

area. It can’t be loaded in PLC EH MPU and there

is no area for saving commentary in EH MPU.)

Following is the operation for each item and relative cautions:

Data transmission between PLC memory card

Function selection

PLC => memory card

a) If password in PLC is unlocked but password in memory card is locked,

data will be wrote into memory card and password in memory card will be

disable after executing PLC => memory card.

b) If password in PLC is locked and no matter password in memory card is

locked or not, data and password in PLC will be wrote into memory card

after executing PLC => memory card.

memory card => PLC (PLC must be in STOP mode)

It will compare password in memory to password in PLC before executing. If

passwords are not the same, it can’t read data.

Note: “Lock state” means password in memory card is locked.

Data is transmitted between WPL working area memory card [program]

Function selection

WPL working area => memory card

a) If you don’t input any words in password field (password field is blank),

password in memory card will be clear after pressing Enter button (no

matter it has password or not before).

b) If you input new password in password field, password in memory card

will be protected by this new password.

memory card => WPL working area

If there is password for memory card, you will be asked to input password

when executing this function. If you don’t input password or input error

password, it will have error message and can’t read data.

Note: “Lock state” means password in memory card is locked.

Data transmitted between WPL working area memory card [commentary]

Function selection

WPL working area => memory card

a) You can select devices to save in memory card. Default is all devices.

After you select, all device you select with commentary will save in

memory card.

b) For device M and D, special D(D1000~D1999) and special

M(M1000~M1999) won’t be wrote into memory card.

c) The commentary capacity in memory card is 32KB. It can save 16000

Chinese words or 32000 letters.

Memory card => WPL working area

To upload commentary in memory card to WPL working area for user to edit

or modify.

Note: “Lock state” means password in memory card is locked.

3

Installation and Maintenance

Please make sure that PLC is power off and

open extension slot cover before installing or

removing function card or memory card. The

installed position of function card and memory card

are shown at the right side. Please attach terminal

label shipped with package on correct terminal to

avoid error wiring.

B

Function card installation – Please put function card into slot vertically and tighten accessory screws into

correct position.

B

Remove function card

Backup memory card installation (change switch to On or Off by requirement)

and removal

Installation

Removal

Check for finishing installation

After PLC is power on, connect PLC to WPLSoft at PC side. In WPLSoft, select view -> working

area and then select connected model to connect. At this time, WPLSoft will detect configuration of PLC

MPU system and show the result, including categories of function card and state of memory card (On or

Off), in working area. Refer to WPLSoft user manual for detail.

4

Application

All kinds of function card provided by DVP series solve the problem that happened in PLC application.

For example:

Usage timing and application requirement

solution (correspond to

function card model name)

When system specification is modified, there are not enough points for

use. And you need only 1~4 input points or 1~2 output points.

Use DVP-F4IP or

DVP-F2OT

Output point of MPU is relay and you need 1~2 points more with transistor

type.

Use DVP-2OT

There is space limit for installing and need to deal with analog signal.

Use DVP-F2AD or

DVP-F2DA

You need 1~2 analog output points to control AC drive speed.

Use DVP-F2DA

Small control system and need 1~2 analog input points.

Use DVP-F2AD

You need to connect PLC to PC and HMI and also control AC drive.

Use DVP-F232S or

DVP-F485S

There are many PLCs and need to download program quickly. (copy PLC) Use DVP-256FM

When parameters want to set by DIP switch without occupy any input

points.

Use DVP-F8ID

When built-in COM 2 is RS-485, but what you need is RS-232 or RS-422. Use DVP-F232 or

DVP-F422

When remote control PLC is by MODEM.

Use DVP-F232

When there are 3~8 variables needed to modify by requirement very

often.

Use DVP-F6VR

Following is application for DI/DO card and AI/AO card:

DVP-F4IP application:

Terminal Layout

DC24V

S/S

AX0

AX1

AX2

AX3

switch 1

switch 2

switch 3

detector

Program

M1104

M1107

M1106

M10

M11

Y0

TMR

T0

K1000

M1105

Explanation

1

The input terminals AX0~AX3

correspond to devices

M1104~M1109

2

Adding input points AX0~AX3.

External switches 1~3 and

detector control M10, M11, Y0

and T0 separately according to

program.

DVP-F2OT application:

Terminal Layout

AY0

AC0

AY1

AC1

DC5~30V

F1

F2

external load 1

external load 2

F1 and F2 are fuses with 0.5A

Program

X10

M10

M1112

M1113

Explanation

1

The output terminals AY0~AY1

correspond to devices

M1112~M1113.

2

Adding output points AY0 and

AY1 and connect to load 1 and

load 2 to be controlled by X10

and M10.

DVP-F2AD application:

Terminal Layout

V0+

I0+

V1+

I1+

COM

detector (voltage)

detector (current)

GND

common terminal

Program

M1000

MOV

D1056

D0

MOV

D1110

D1

CH0

M1000

MOV

MOV

CH1

D11

D1057

D1111

D10

Explanation

1

CH0 AD is variable. Current value

is D0 and average value is D1.

2

CH1 AD is variable. Current value

is D10 and average value is D11.

Conversion calculation of CH0 AD:

Conversion calculation of CH1 AD:

4000

1472

0

+10V

?

Digital

output

analog input

Detector (voltage) produces

an input voltage CH0. If the

value D1 reads is K1472, it

means input voltage is

V

V

68

.

3

4000

10

1472

=

×

=

0

?

2000

1234

20mA

digital

output

analog input

Detector (current) produces

an input current CH1. If the

value D11 reads is K1234, it

means input current is

mA

mA

34

.

12

2000

20

1234

=

×

=

DVP-F2DA application:

Terminal layout

V0+

I0+

V1+

I1+

COM

ACM

AVI

ACM

ACI

current output

AC drive 1

voltage output

AC drive 2

Program

MOV

D0

D1116

CH0

MOV

CH1

D1117

D1

M1000

M1000

Conversion calculation of CH0 DA:

Conversion calculation of CH1 DA:

0

?

12.34

20mA

4000

analog

output

digital output

The current is outputted to

ACI of AC drive to be speed

control. If you need current

12.34mA, you should give

D0:

2468

20

4000

34

.

12

=

×

=

mA

mA

0

?

4000

5.23

+10V

analog

output

digital input

The voltage is outputted

to AVI of AC drive to be

speed control. If you

need voltage 5.23V, you

should give D1:

2092

10

4000

23

.

5

=

×

=

V

V