Delta Electronics Function Card DVP-EH User Manual

Dvp-eh, Function card, Instruction sheet

http://www.delta.com.tw/products/plc.asp

DVP-EH

Function Card

Instruction Sheet

1

WARNING

Always read this manual thoroughly before using Function Extension Card.

This instruction provides electrical specification, function specification, wiring and basic program

design. For detail program design and instruction explanation information refer to PLC Application

Manual (programming).

This is an OPEN-TYPE. When installing, you should turn MPU power off and have static

electricity protection, such as wear antistatic gloves, to avoid damage those components on

function extension card caused by statics.

This instruction is for DVP series function extension card. Please find out your order model in the

following for correct usage.

2

INTRODUCTION

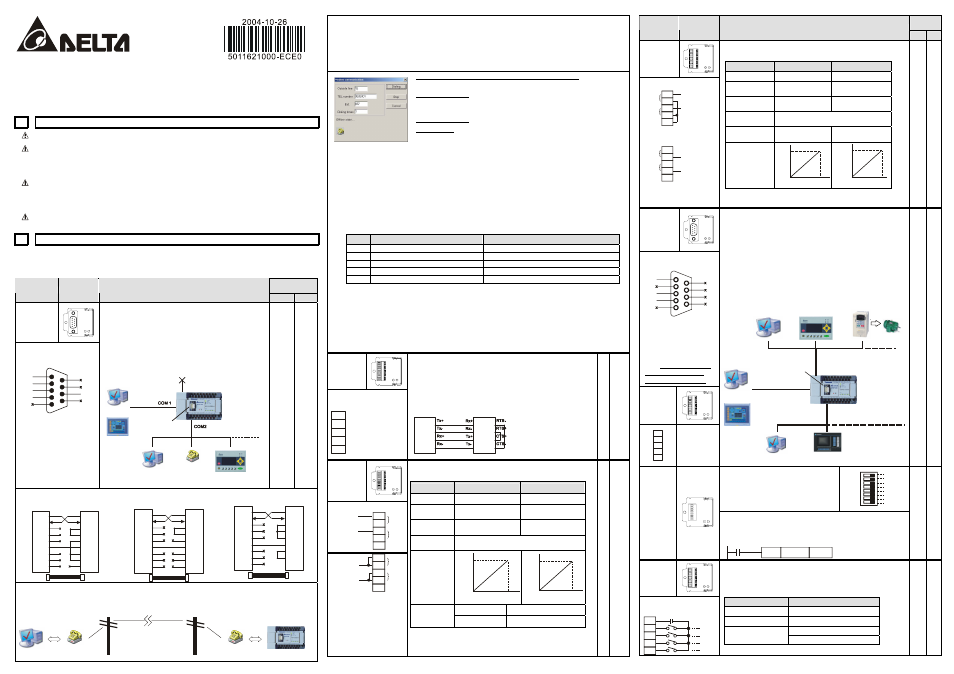

Thank you for choosing DELTA’s PLC extension card of DVP-EP/EH Series. There are analog

input/output card (AI/AO), digital input/output card (DI/DO), extension card for communication port and

memory card. Refer to following table for detail.

Applicable

Model

Model Name

Outline

Function Explanation

EP

EH

DVP-F232

(RS-232 card)

Terminal Layout (DB-9

male)

V. High: high potential, i.e. logic 1

GND

V. High

Tx

Rx

V. High

5

3

2

1

9

8

7

6

4

Note:

Please pay attention for

pin 2 and pin 3 when

connecting this

communication port to

PC or HMI.

MPU built in COM1(RS-232) and COM2(RS-485).

When connecting RS-232 to PC or other peripheral,

such as MODEM, by using COM2, you can use this

extension card. The communication function is the

same as COM2 except communication interface, i.e.

there are Slave mode and Master mode for you to

choose. Note: PLC will set that COM2 is occupied by

RS-232 card and built-in COM2 (RS-232) function will

be invalid after inserting this card. Refer to following for

system connection.

PC

HMI

or

DVP EP/EH

MPU

select one

device

Master/Slave

(RS-232)

extension card for

communication port

DVP-F232 DVP-F422

or

MODEM

PC

HMI

RS-485 is invalid

○

○

Application example for connection in Slave mode

3

2

7

8

6

5

1

4

9

7

8

6

5

1

4

9

3

2

PLC COM2

PC RS-232

serial port

DB-9

FEMALE

DB-9

FEMALE

Tx

Tx

Rx

Rx

Rl.

GND

S.G.

3

2

7

8

6

5

1

4

9

7

8

6

5

1

4

9

3

2

PLC COM2

DB-9

FEMALE

DB-9

MALE

Tx

Tx

Rx

Rx

GND

S.G.

Delta HMI

DOPA series

3

2

7

8

6

5

1

4

9

7

8

6

5

4

3

2

PLC COM2

DB-9

FEMALE

MALE

Tx

Tx

Rx

Rx

GND

S.G.

DB-25

20

HITECH

HMI

Application example for connecting in Master mode

After inserting DVP-F232 card into MPU, you can use WPL to monitor or upload or download via

MODEM connection. First, you should connect PC and PLC to MODEM separately at the two end of

network and turn MODEM power on to operate by following steps.

PC

WPLSoft

is executing

DVP-EP/EH

series MPU

DVP-F232

interface

MODEM

MODEM

telecommunication

network

STEP 1: Setting M1184=On on PLC side (start-up MODEM)

STEP 2: Setting M1185=On (start-up PLC’s MODEM initialization)

STEP 3: Check the result of MODEM initialization: M1186=On means succeed to initial. M1187=On

means fail to initial.

STEP 4: After initialing successful, WPL software can be ready for connection on remote PC side. WPL

connection method: setting -> modem connection (you need to install modem’s driver first) -> to

get dial connection dialog box and then fill in dial information as following.

If you dial a number to access an outside line, what is it? Please fill in this

field when it is necessary.

Telephone number: if there is any area code or city code, you don’t need

to put anything for distinction. Only key the figure one by one directly.

For example: 88633626301

Extension number: Please fill in the field when it is necessary.

Dialing times: setting redial times when it is fail to connect.

After finishing input, execute dialing to start connection.

After dialing connection successfully, dial connection dialog box will disappear automatically. Now,

you can monitor remote PLC via WPL. If there is remote control signal detected on PLC side, M1188

will be On and user can know if PLC is monitored by remote control via this special M.

Note:

1. Communication baud rate can’t be changed during MODEM connection. MODEM connection

baud rate on PLC side is fixed to 9600bps and can’t be modified.

2. The MODEM that connected to PLC must provide Auto Answer (AA) function. Communication

baud rate for MODEM at two end should be 9600bps and higher.

3. EP/EH series special M definition for MODEM connection: (following special M is valid when PLC is

RUN/STOP.

Device

Function Explanation

Remark

M1184 Start-up MODEM

When M1184=On, following actions are valid.

M1185 Start-up MODEM initialization

This flag will be Off after finishing initialization.

M1186 Fail to initial MODEM

When M1185=On, M1186=Off.

M1187 Succeed to initial MODEM

When M1185=On,M1187=Off.

M1188 Display if MODEM is connected or not On means in connection

4. Additional explanation on PLC side:

a) It must use with RS-232 card when connecting MODEM on PLC side. If not, above special M

are invalid.

b) You must set M1185=On to initial MODEM after MODEM start-up (M1184=On). If not, it can’t

start-up MODEM auto dial function on PLC side.

c) MODEM will enter auto dial mode after initialization.

d) MODEM will enter to ready for dial mode on PLC side after remote PC stops connection. If user

turn MODEM power off now, it should need to initial at the next time when turning on MODEM.

e) The initial format that used to MODEM on PLC side are ATZ and ATS0=1.

DVP-F422

(RS-422

card)

Terminal Layout

Tx+

Tx

-

Rx+

Rx-

GND

Tx+: transmission

(+)

Tx-: transmission

(-)

Rx+: receive (+)

Rx-: receive (-)

User can use COM2 to connect RS-422 and HMI or other

peripheral for long distance connection. The communication

function is the same as COM2 except communication

interface. Note: PLC will set that COM2 is occupied by RS-422

card and built-in COM2 (RS-485) function will be invalid after

inserting this card. Refer to following for system connection.

Wiring example

1

2

3

4

6

7

8

9

DVP-F422

COM2/DB-9

PLC COM2

Delta HMI

series

DOPA

2

1

3

4

MODE 1: RS-232

MODE 2: RS-422

MODE 3: RS-485

Delta HMI

series:

DOPA

RS-422 is at

COM2, and need to set to MODE 2,

Refer to following for setting :

○

○

DVP-F2AD

Terminal layout

V0+

I0+

V1+

I1+

COM

CH0

CH1

Voltage input

0~10V

0~10V

V0+

I0+

V1+

I1+

COM

CH0

CH1

current input

0~20mA

0~20mA

Input signal limit:

Voltage: less than 12VDC

(Inputting negative voltage

is banned)

Current: less than 30mA

(Inputting negative current

is banned)

There are 2 analog input points supported by F2AD card and

their characteristics are shown in the following:

Item

Voltage input

Current input

Analog signal

DC 0~+10V

DC 0~20mA

Resolution

(12bit)

2.5mV (10/4000)

10uA (20/2000)

Input

impedance

40KΩ 250Ω

update time

for conversion

D1118 setting (≧K5, unit: ms)

Characteristic

cure

4000

10V

0

Digital

output

voltage input

0

20mA

2000

Digital

output

current input

Current value

D1056 (CH0) D1057 (CH1)

Digital value

output

Average value

D1110 (CH0) D1111 (CH1)

User can get A/D conversion value saved in special D by

reading special D that corresponds to current value or average

value. D1118 setting is every update time of current value of

digital value output.

○

○

Applicable

Model

Model Name

Outline

Function Explanation

EP

EH

DVP-F2DA

Terminal layout

V0+

I0+

V1+

I1+

COM

0~+10V

0~+10V

CH0

CH1

Voltage output

output load: 1K~2MΩ

V0+

I0+

V1+

I1+

COM

CH0

CH1

current output

0~20mA

0~20mA

output load: 0~500Ω

There are 2 analog output points supported by F2DA card and

their characteristics are shown in the following:

Item

Voltage output

Current output

Analog signal

DC 0~+10V

DC 4~20mA

Output

impedance

Less than 0.5Ω

Less than 0.5Ω

Resolution

(12bit)

2.5mV (10/4000)

5uA (20/4000)

Update time

for conversion

D1118 setting (≧K5, unit: ms)

Digital value

input

D1116 (CH0)

D1117 (CH1)

Characteristic

cure

4000

10V

0

voltage

output

digital input

digital input

0

20mA

4000

current

output

User can move value to D1116(CH0) or D1117(CH1) to get

correspondent output voltage by using instruction MOV.

○

○

DVP-F232S

(RS-232

card)

Terminal Layout (DB-9

female)

GND

Tx

Rx

5

3

2

1

9

8

7

6

4

NC

NC

NC

NC

NC

NC

Note:

Please pay attention to

signal of pin2 and pin3

when this

communication port is

connected to PC or

HMI. Especial that this

definition is different

from DVP-F232 card.

DVP-F485S

(RS-485

card)

D+

D-

D + : signal

(+)

D - : signal

(-)

When two built-in COM1(RS-232) and COM2 (RS-485)

are not enough for use, you can add one COM by this card

(number is 3 and is called COM3. There are two interfaces,

RS-232 and RS-485, for you to use. Its general function is the

same as COM1 but communication baud rate is

9600/19200/38400 bps. PLC scan time will be added at least

0.8ms ~ 2ms due to COM3.

Usage limit: PC1 and PC2 can’t execute ladder diagram

monitor function simultaneously when COM2 is slave mode

and connect to PC1 with executing WPLSoft and COM3 also

connects to PC2 with executing WPLSoft. But other

communication function is normal. COM1 is out of this limit.

Master

PC 2

HMI

PC

PC 1

HMI

COM1

COM2

COM3

(RS-232)

(RS-485)

DVP-F232S or DVP-F485S

DVP EH

MPU

AC drive or Servo

Extension card for

communication port

select one Master device

or

╳

○

This digital DIP switch card provides

8 On/Off input signals (DI0~DI7) to

read value by using instruction API

109 SWRD. It is general used to be

input interface of external data setting

and doesn’t occupy input point X.

ID0

M1104

M1105

M1106

M1107

M1108

M1109

M1110

M1111

ID1

ID2

ID3

ID4

ID5

ID6

ID7

DVP-F8ID

After system finishes every scan time, it will auto to read 8 bits

of digital switch and set each state in special auxiliary relay

M1104~M1111. User can use this 8 special M to operate in the

program. Refer to following example:

M1000

MOV K2M1104 D1120 Setting PLC ID by DIP switch

○

○

DVP-F4IP

Terminal layout and

wiring

+24V

S/S

AX0

AX1

AX2

AX3

M1104

M1105

M1106

M1107

F4IP card provides 4 digital input points with photo coupler

isolation between PLC. After system finishes scan every time,

it will read 4 bits of these 4 digital input points automatically

and set the states separately in M1104~M1107. User can

operate this four special M in the program directly.

Item

Input Spec.

Input type

DC(SINK or SOURCE)

Input signal current

About 5mA/DC24V

Off→On, 16VDC and higher

Action level

On→Off, 14.4VDC and lower

○

○