Preventive maintenance – WaterFurnace Envision Hydronic (NSW) User Manual

Page 48

48

NSW INSTALLATION MANUAL

Preventive Maintenance

1. Keep all air out of the water lines. An open loop system

should be checked to ensure that the well head is not

allowing air to infiltrate the water line. Lines should

always be airtight.

2. Keep the system under pressure at all times. In open

loop systems, it is recommended that a water control

valve be placed in the discharge line to prevent loss of

pressure during off cycles. Closed loop systems must

have a positive static pressure.

NOTES: If the installation is performed in an area with

a known high mineral content in the water, it is best to

establish a periodic maintenance schedule to check the

water-to-refrigerant heat exchanger on a regular basis.

Should periodic cleaning be necessary, use standard

cleaning procedures which are compatible with either the

cupronickel or copper water lines. Generally, the more water

flowing through the unit, the less chance there is for scaling.

Low GPM flow rates produce higher temperatures through

the coil. To avoid excessive pressure drop and the possibility

of copper erosion, do not exceed GPM flow rate as shown

on the specification sheets for each unit.

Cleaning Procedure

1. Close the inlet and outlet water valves to isolate the heat

pump from the well system, water heater or loop pumps.

2. Disconnect piping and remove solenoid valve, pumps, etc,

from the inlet and outlet connections on the heat pump.

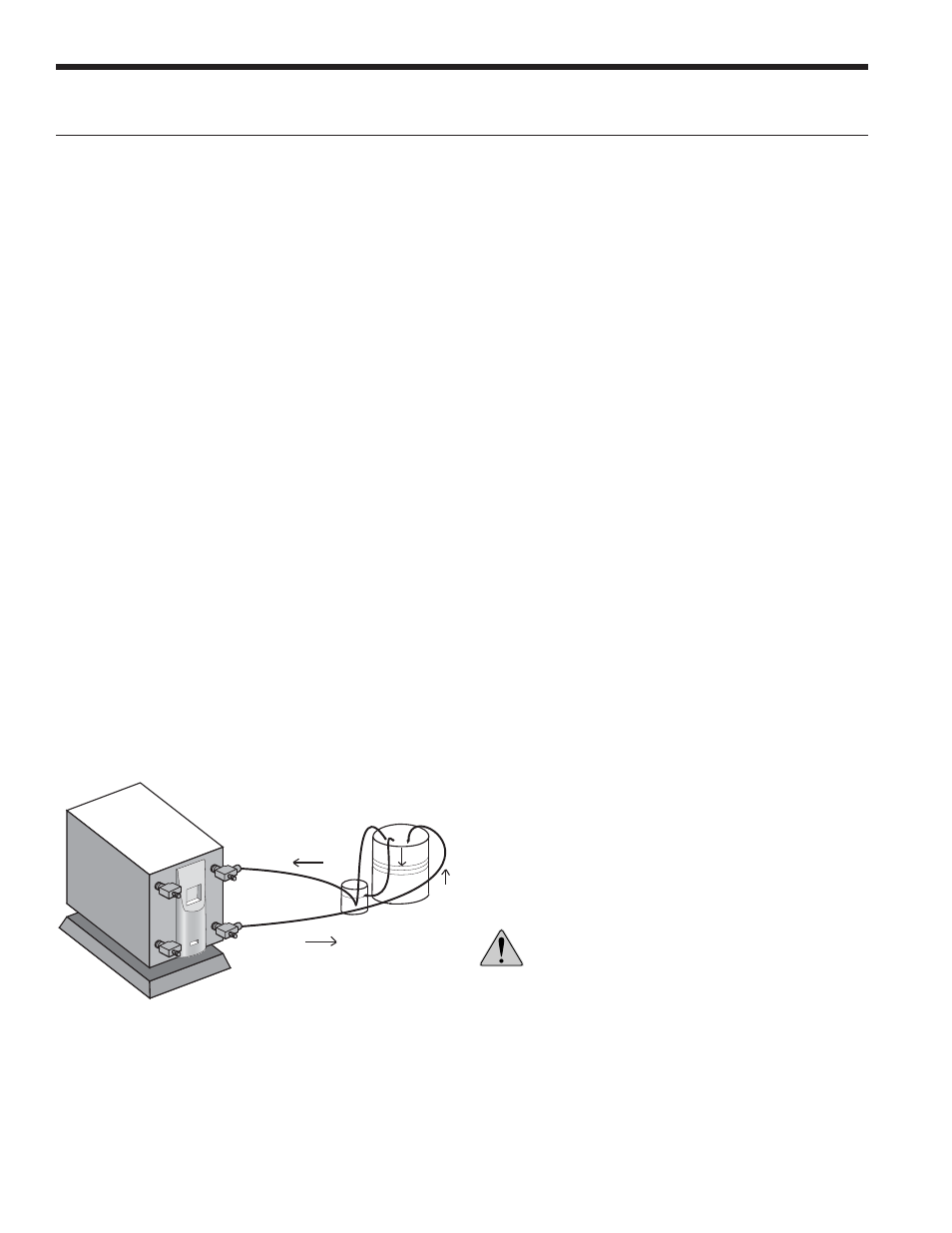

3. Connect plastic hoses from the circulating pump* to the

outlet of the water-to-refrigerant heat exchanger to be

de-limed (refer to the Cleaning Connections illustration).

4. Connect a plastic hose from the circulating pump inlet

to the bottom of a plastic five (5) gallon pail (refer to

the Cleaning Connections illustration).

5. Connect a plastic hose from the inlet line of the water-

to-refrigerant heat exchanger to the plastic pail. Secure

tightly to ensure that circulating solution does not spill

(refer to the Cleaning Connections illustration).

6. Partially fill the plastic pail with clear water (about two-

thirds full) and prime the circulating pump. Circulate

until lines are full.

7. Start the circulating pump and slowly add a commercial

scale remover** to the water as recommended by the

scale remover manufacturer’s directions.

8. Be sure the pump circulation is opposite to the normal

water flow through the water-to-refrigerant heat exchanger.

9. Maintain re-circulation until all scale and other material

has been dissolved and flushed from the heat exchanger.

10. Upon completion of the procedure. Safely dispose of

the solution.

11. Rinse the pump and plastic pail. Refill with clear water.

12. Start the pump circulation and flush the system until all

acid residue has been removed from the system. Refill

the plastic pail until only clear water is circulated.

13. Turn off the circulating pump and disconnect all hoses

and fittings.

14. Replace solenoid valves, pumps, hoses and other

devices in their original locations. On closed loop

systems, be sure to purge between the flow center and

unit to avoid getting air into the loop.

15. Put the heat pump back into operation. Check for

proper operating temperature.

NOTES: *Virginia Chemical Co. makes a Pump model H460.

* W.W. Granger Co. sells a Pump #2P-017 made by Little Giant.

**Virginia Chemical Co. makes a liquid ice machine cleaner which should be used on water-to-refrigerant heat exchangers

serving a domestic hot water system. Calci-Solve by NYCO is available for use on other heat exchangers

Cleaning Connections

WARNING: This process involves a caustic

solution and may be harmful to people and

animals. Wear protective equipment (glasses,

rubber gloves, apron, etc.)

Five-gallon Bucket

Pump