Vortech 2003-2005 Lexus 3.0L IS300 User Manual

Page 14

P/N: 4LA020-010

©2007 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

11JUL07 v1.1 Lexus(4LAv1.1)

6

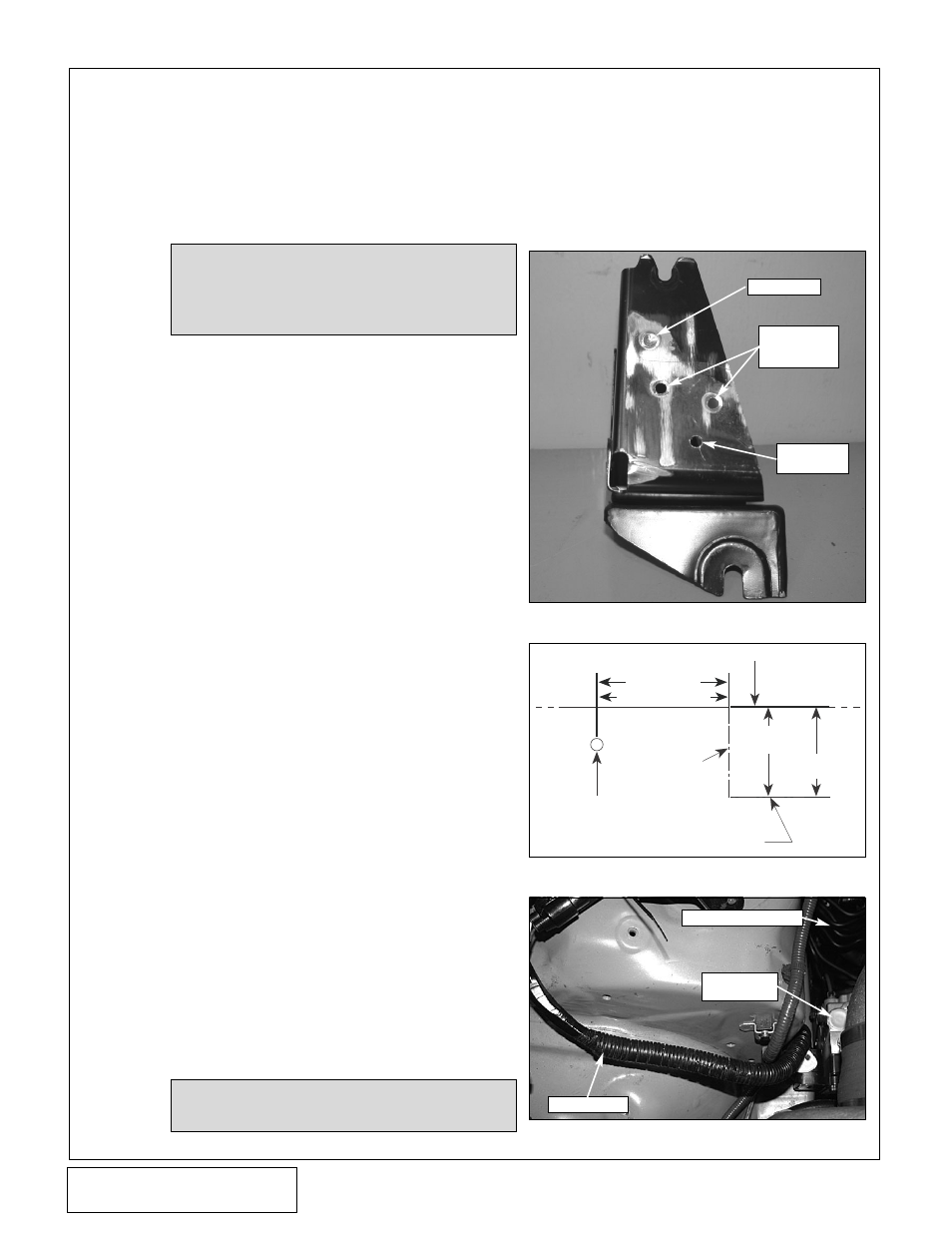

Fig. 4-a

Fig. 4-b

TOP OF FRAME RAIL

BOTTOM EDGE

OF BRACKET

FRONT EDGE

OF BRACKET

FACTORY

STUD

3.5" '02-'05 MODEL YRS

2" '01 MODEL YR

2.4" '02-'05

MODEL YRS

1-5/8" '01

MODEL YR

Fig. 4-c

A.

Locate the ABS module bracket removed in

Section 1. Remove the three spot welds that

hold the side support to the main cradle.

Separate the side support from the main cra-

dle and discard. Drill the two lower spot weld

locations to Ø3/16" and add an annitional

Ø3/16" hole as shown. (See Fig. 4-a.)

B.

(2001 Model Year Only, 2002 and Later

Skip to B-2.)

—

1.

Measure 2" back from the stud that previ-

ously secured the bottom of the ABS

bracket and make a mark. At the previ-

ously marked location, measure down 1-

5/8" from the top of a frame rail and make

a second mark. Align the front and bottom

edges of the bracket where the two marks

intersect. Using the modified bracket as a

template (see Fig 4-a) to mark the three

hole locations on the frame rail. Drill the

hole locations using a 1/8" drill bit. Secure

the ABS bracket to the frame rail using

the supplied selt-tapping hardware. Cut

the factory stud that previously secured

the ABS bracket flush wiith the frame.

(See Fig. 4-b.)

(2002-2005 Model Years Only)

,

2.

Measure 3.5" back from the stud that pre-

viously secured the bottom of the ABS

bracket and make a mark. At the previous-

ly marked location, measure down 2.4"

from the top of the frame rail and make a

second mark. Align the front and bottom

edges of the bracket where the two marks

intersect. Using the modified bracket as a

template (see Fig. 4-a) to mark the three

hole locations on the frame rail. Drill the

hole locations using a 1/8" drill. Secure the

ABS bracket to the frame rail using the

supplied self-tapping hardware. Cut the

factory stud that previoisly secured the

ABS bracket flush with the frame. (See

Fig. 4-b

.)

C.

Remove the 10mm headed screw that

secures the plastic brake line separator and

discard. Remove the brake lines from their

plastic separator located on the frame rail.

Slightly bend the lines running to the ABS

module so that it may be repositioned to its

new location. Secure the module to the relo-

cated bracket using the factory hardware.

4.

ABS RELOCATION

NOTE:

Use caution when bending these lines.

Make bends as large as possible to

avoid kinking.

NOTE:

The preferred method of removing a

spot weld is the use of a spot weld cut-

ting tool. However in this application,

the use of an approximate sized drill or

a right-angle grinder is acceptable.

D.

Locate the ABS module harness.

Carefully split the plastic flex-loom

exposing the wires from the ABS

connector to the main harness on

the shock tower. Separate enough

length to reach the relocated ABS

module and re-wrap the flex-loom.

Reconnect the harness plug to the

ABS module. (See Fig. 4-c.)

LINES SLIGHTLY BENT

RELOCATED

ABS MODULE

ABS HARNESS

SPOT WELD

NEW HOLE

LOCATION

SPOT WELDS

DRILLED

THROUGH