Vortech 2005-2008 C6 Corvette User Manual

Page 11

P/N: 4GS020-010

©2009 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

12MAY09 v3.1 05-08Corvette(4GSv3.1)

2

A.

Remove the front wheels from the vehicle.

B.

Remove the steering rack ball joints from the

spindle on each side of the vehicle.

C.

Temporarily remove the front anti-roll bar from

the vehicle and set aside.

D.

Remove the two nuts and bolts securing the

steering rack to the cross member.

E.

Remove the two remaining screws from the

ABS mounting bracket.

F.

Remove the two screws securing the power

steering cooler (if equipped) and move the

cooler out of the way.

G. With the steering wheel pointed to the left as

far as it will go, carefully lift the rack until it

comes to a stop against the frame rail on

both sides. Move it around to provide maxi-

mum clearance.

H.

Secure the rack in this position by blocking it

up or securing it from above with tie-downs

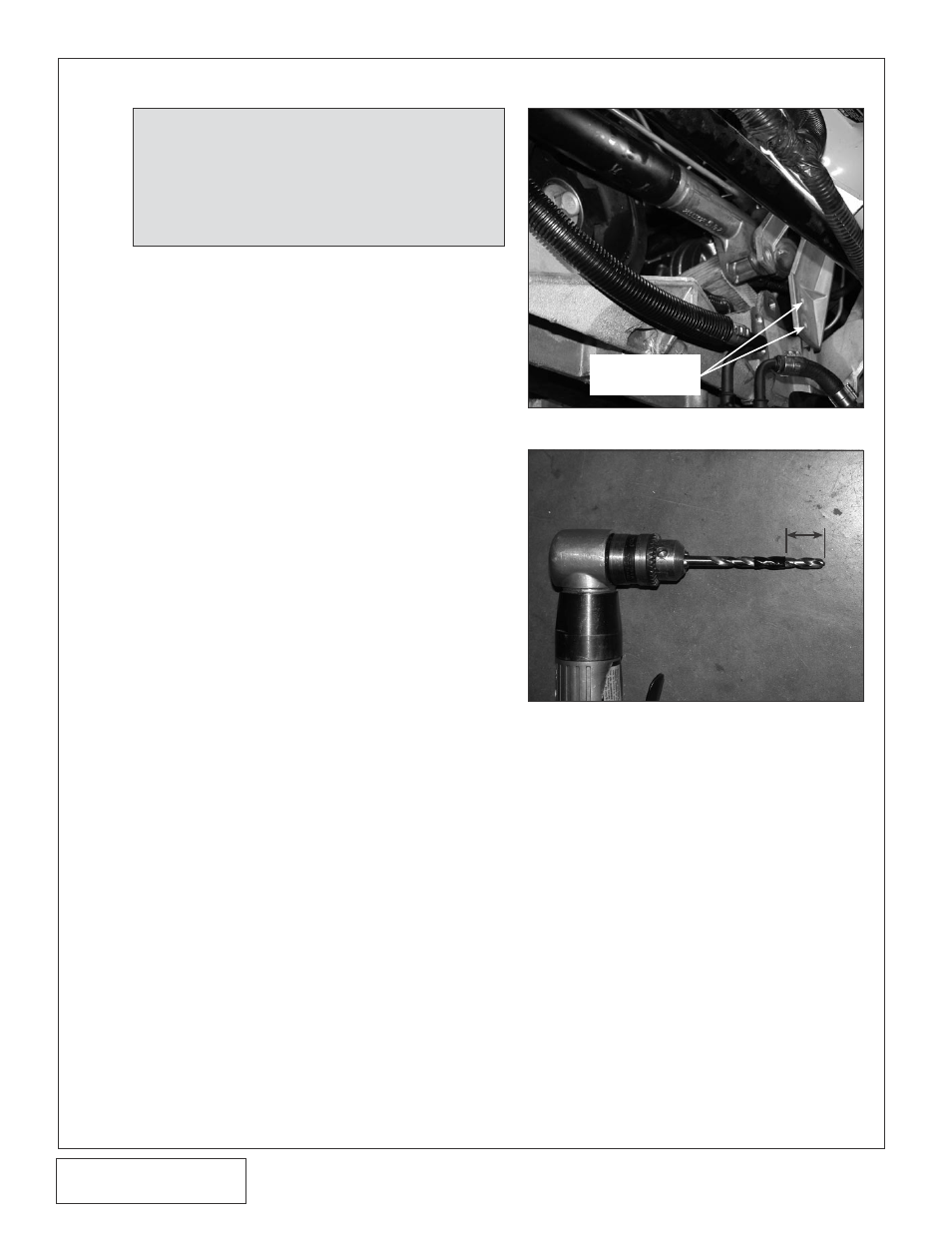

etc. (See Fig. 2-a.)

I.

Disconnect the wiring and remove the engine

starter hardware. Push the starter forward out

of the way and install the GM J342386 fly-

wheel holding tool in the starter location to

keep the engine from spinning.

J.

Remove the crankshaft damper bolt.

K.

Install the supplied drill guide with the raised

section piloting in the damper bore. Secure in

place by installing the supplied socket head

cap screw of the correct length. Do not over-

tighten the screw as it may distort the drill

guide (its purpose is just to hold the guide in

place while drilling). (See Fig. 2-c.)

L.

Using a small drill motor, mark a Ø1/4" drill bit

with electrical tape or a drill stop so that the

hole will be deep enough for the supplied 1/2"

long dowel pin. (See Fig. 2-b.) (The drill

bushing is 1/2" long, so with the guide

installed, the drill should go in at least 1" from

the front of the drill bushing.)

M. Make sure that when drilling the hole, the tool

remains perpendicular to the damper. Use

extra care.

N.

Remove the Socket head cap screw and drill

guide.

2. HARMONIC DAMPER DOWEL PIN INSTALLATION

NOTE: The purpose of this section is to provide access to the

harmonic damper bolt area so that the crankshaft can be

pinned to the damper to prevent the damper from spin-

ning on the crank shaft. The following steps will work on

all or most applications. If it is not possible to get ade-

quate clearance by performing the following steps, follow

the manufacturers steps for removing the harmonic

damper until there is sufficient room to work in.

Fig. 2-b

Fig. 2-a

1" MINIMUM

ABS MOUNTING

BRACKET

SCREWS