Delta Electronics Position Control Module DVP01PU-H User Manual

Position control module instruction sheet

http://www.delta.com.tw/industrialautomation/

5011627802-1PE2

2006-12-08

Position Control Module

Instruction Sheet

Warning

3

This Instruction Sheet only provides descriptions for installation, wiring and trial run. For further infromation, please

refer to special module of PLC Application Manual.

3

Do NOT touch terminals when power on. Please turn off the power before wiring.

3

This is an OPEN TYPE PLC. The PLC should be kept in an enclosure away from airborne dust, humidity, electric shock

risk and vibration. Also, it is equipped with protective methods such as some special tools or keys to open the enclosure, in

order to prevent hazard to users or damage the PLC.

3

Do NOT connect the AC input power to any of the input/output terminals, or it may damage the PLC. Check all the wiring

prior to power up.

X

Introduction

1.1

Model Explanation and Peripherals

01PU (position control unit) is mainly applied to the

speed/position control of step/servo driven system.

The maximum output pulse can be up to 200 KPPS,

and built-in various route control modes. The

DVP-PLC EH series can read/write 01PU via

FROM/TO instrucitons. There are 54 CRs(Controlled

Register) in 01PU and 16 bits for each register. The

32-bits data is composed of 2 continuous CR number.

Nameplate

Power input specification

Delta PLC model name

24Vdc 3W

Differential Line Driver

01PU-H0T4320001

VX.XX

Output module specification

Bar code, serial No,

firmware version

Model & Serial Number

Serial Number

Production No.

Production week

Production plant (Taoyuan)

Version No.

Model name

Model

DVP series

Number of channels

Model type

For EH series MPU

PU Position control module

:

Production year (2004)

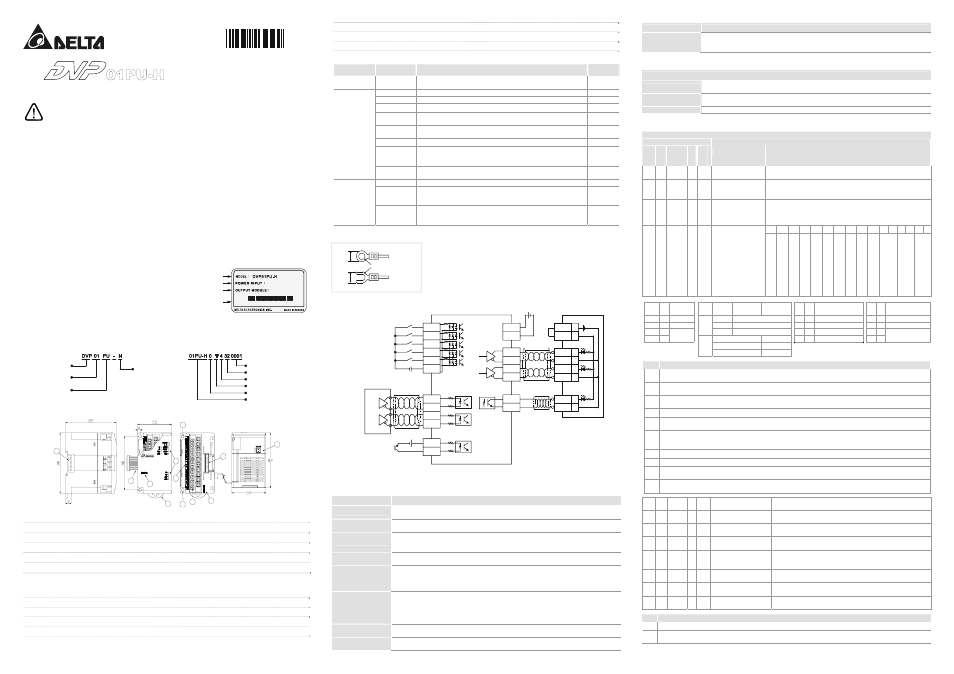

1.2

Product Profile and Outline (LED Indicator and Terminal Block)

1

5

2

3

7

4

8

7

6

3

10

9

Unit: mm

1. DIN rail track (35mm)

2. Mounting wire to connect extension module/extension unit

3. Model name

4. Status Indicator (Power, Run and ERROR)

5. DIN rail clip

6. Terminal

7. Mounting hole

8. Terminal layout

9. Extension port to connect extension module/unit

10. RS-485 communication port

LED Display

POWER : Power indicator, +5V internal power

START : Start input

LV

: Low voltage indicator (lit when external STOP : Stop input

input power is lower than 19.5V)

DOG : DOG (near point signal) input

ERROR : Error occurred indicator. It will blink when FP

: CW pulse output

CR#44 is not 0.

RP

: CCW pulse output

LSP

: Right limit input indicator

ΦA

: A-phase input of manual pulse generator

LSN

: Left limit input indicator

ΦB

: B-phase input of manual pulse generator

PG0

: Zero signal input indicator

CLR

: Output clear signal

Input/Output Terminal

Description

Terminal name

Explanation

Response

character

Power supply

+24V, 0V

Power input/DC24V (-15~+20%)

Current consumption 100mA

-

START

Start input terminal

15ms/50ms

STOP Stop

input

terminal

15ms

LSP / LSN

Input right/left limit

1ms

Φ

A+, ΦA-

A-phase terminal (+, -) of manual pulse generator input

(line driver input)

200KHz

Φ

B+, ΦB-

B-phase terminal (+, -) of manual pulse generator input

(line driver input)

200KHz

PG0+, PG0- Zero signal input terminal +, - (line driver input)

1ms

DOG

Offers two different functions depending on operation mode.

(1) It is near-point signal in zero return mode.

(2) It is start signal on interrupt 1st or interrupt 2nd speed mode.

1ms

Input

S/S

Signal common terminal of these Inputs (START, STOP, DOG,

LSP, LSN)

-

CLR+, CLR- Clear signal (clear signal of internal error counter for Servo drive)

130ms

FP+, FP-

FP/RP mode: CW pulse output

I/O mode: Output pulse

AB-phase mode: A-phase output

200KHz

Output

RP+, RP-

FP/RP mode: CCW pulse output

I/O mode: direction output

AB-phase mode: B-phase output

200KHz

1.3 Wiring

Below 6.8

Below 6.8

To suit M3.5 screw terminals

1. Please wire I/O by O-type or Y-type terminals as the specification shown at

left. The torque of PLC terminal screw should be 5~8 kg-cm (4.3~6.9 in-lbs).

2. I/O signal wires or power supply should not run through the same multi-wire

cable or conduit.

3. Use copper conductors only, 60/75°C.

Input/Output Circuit

DVP01PU-H

START

STOP

LSP

LSN

DOG

S/S

+24V

5-24VDC

+24VDC IN

24V

0V

FP+

FP-

RP+

RP-

CLR+

CLR-

A-phase

Φ

A+

Φ

A-

Φ

B+

PG0+

PG0-

5-24VDC

PLS

/PLS

SIGN

/SIGN

DI2

COM-

VDD

COM+

17

11

41

43

37

36

10

45

24V

B-phase

Φ

B-

Delta Servo

ASDA series

Manual pulse generator

Shielded cable

Y

Specifications

2.1 Function

Specifications

Item

Description

Power supply

DC24V(-15% ~ +20%), Current consumption 140±30mA

Power is supplied from EH series or external power supply.

Max. number of

connected axes

8 units (axes); (All I/O points are not occupied. There are 8 special extension units at

most to connect to EH series.)

Distance instruction

Distance value is set by CR. 1. Setting value: -2, 147,483,648~+2,147,483,647;

2. Selectable unit: um, mdeg, 10

-4

inch, Pulse; 3. Selectable rate: 10

0

, 10

1

, 10

2

, 10

3

;

4. Selectable position: absolute and relative position instruction

Speed instruction

Speed value is set by CR. 1. Setting value: -2,147,483,648~+2,147,483,647 (conversion

value of 10~200KPPS pulse); 2. Unit selectable: pulse/s, cm/min, 10deg/min, inch/min

External output

Photo coupler is for insulation and there are LED indications for all output/input signals.

Outputs: FP and RP (line driver output 5V)

Output: CLR is the type of NPN open collector transistor output (5~24VDC, less than

20mA)

External input

Photo coupler is for insulation and there are LED indications for all output/input signals.

Input point: START, STOP, LSP, LSN, DOG(contact or open collector transistor, 24VDC±

10%, 5±1mA)

Inputs:ΦA, ΦB(line driver or open collector transistor, 5~24VDC, 6~15mA)

Input: PG0 (line driver or open collector transistor, 5~24VDC, 6~15mA)

Pulse output format

Three selectable modes: Pulse/Dir, FP(CW)/RP(CCW), A/B (all modes are line driver

output)

Position program &

data transmission

The DVP-PLC EH series can read/write data in CR via FROM/TO instrucitons. The 32-bits

data is composed of 2 continuous CR number. The range of 16-bits CR is CR#0~CR#53.

Item

Description

Connect to DVP-PLC

in series

When DVP-01PU modules are connected to an MPU, the modules are numbered from 0

to 7. 0 is the closest and 7 is the farthest to the MPU. 8 modules is the max and they do

not occupy any digital I/O points of the MPU.

2.2 Other

Specification

Environmental specifications

Operation/Storage

1. Operation: 0°C~55°C (Temperature), 50~95%(Humidity), pollution degree 2

2. Storage: -25°C~70°C (Temperature), 5~95%(Humidity)

Vibration/Shock

immunity

Standard: IEC1131-2, IEC 68-2-6 (TEST Fc)/ IEC1131-2 & IEC 68-2-27 (TEST Ea)

Antistatic spec.

All places between terminals and ground comply with the spec.

Z

Control Register

DVP-01PU Position Control Unit

CR No.

HW LW

Address

Latched

Attribute

Content

Setting Range

#0 H’4190 9

R

Model No.

System setting, Read-only (The model number of DVP-01PU is

H’0110.)

#2 #1 H’4191 9 R/W

Pulse required to

rotate motor for 1

revolution (A)

Range: 1 ~ +2,147,483,647 PPS/REV, factory setting: 2,000

Pulse/Revolution (PLS/REV)

#4 #3 H’4193 9 R/W

Machine travel

range while motor

rotate for 1

revolution (B)

Range: 1 ~ +2,147,483,647 unit/REV,

Factory setting: 1,000 (unit*1/REV)

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

#5 H’4195 9 R/W

Parameter setting

Factory setting:

H’0000

ST

OP

input polarity

ST

AR

T

input

polarity

ST

AR

T

response time

Acceleration curve options

DOG polarity

DOG trigger time

Pulse direction

Zero return direction

LSN input polarity

LSP

input polarity

Pulse output format

Position rate setting

Unit setting

b1 b0

Unit

Motor

unit

Combined

unit

Machine

unit

b3 b2

Position rate

setting

b5 b4

Pulse output

format

0

0

Motor

pulse

um 0 0

10

0

0 0

FP + RP

0

1 Machine

pulse

m deg

0 1

10

1

0 1 Pulse + direction

1

0

Position

pulse

10

-4

inch 1 0

10

2

1 0

1

1

Combined

pulse/sec cm/min

1 1

10

3

1 1

A/B Phase pulse

pulse/sec

10deg/min

S

peed

pulse/sec inch/min

bit #

Description

6

When b[6]=0: positive logic, LSP input signal is ON, LPS signal is given.

When b[6]=1: negative logic, LSP input signal is OFF, LPS signal is given.

7

When b[7]=0: positive logic, LSN input signal is ON, LSN signal is given.

When b[7]=1: negative logic, LSN input signal is OFF, LSN signal is given.

8

When b[8]=0: zero return is executed to the direction of CP’s decreasing value. When b[8]=1, zero return is

executed to the direction of CP’s increasing value.

9

When CW running is executed: if b[9]=0, CP value is increasing. If b[9]=1, CP value is decreasing.

10

When b[10]=0: DOG rising-edge is triggered. When b[10]=1,DOG falling-edge is triggered. (Interrupt 1st and

interrupt 2nd speed position modes are enabled.)

11

When b[11]=0: positive logic, DOG input signal is ON, DOG near point signal is given.

When b[11]=1: negative logic, DOG input signal is OFF, DOG near point signal is given.

When in zero return mode, interrupt 1st and interrupt 2nd speed position modes are enabled.

12 When b[12]=0: trapezoid acceleration line is chosen. When b[12]=1, S acceleration line is chosen.

13 When b[13]=0: 15ms; when b[13]=1: 50ms(for noise filter).

14

When b[14]=0: positive logic, START input signal is ON, START input.

When b[14]=1: negative logic, START input signal is OFF, START input.

15

When b[15]=0: positive logic, STOP input signal is ON, STOP input.

When b[15]=1: negative logic, STOP input signal is OFF, STOP input.

#7 #6 H’4196 9 R/W Maximum speed V

max

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200K PPS) *2

Factory setting: 200,000 unit*1

#9 #8 H’4198 9 R/W

Bias speed V

bias

Range: 0 ~ +2,147,483,647 unit*1 (0 ~ 200K PPS pulse

transfer value) *2Factory setting: 0 unit*1

#11 #10 H’419A 9 R/W

JOG speed V

JOG

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200K PPS pulse

transfer value) *2Factory setting: 5,000 unit*1

#13 #12 H’419C 9 R/W Zero return speed V

RT

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200K PPS pulse

transfer value) *2Factory setting: 50,000 unit*1

#15 #14 H’419E 9 R/W

Zero return

deceleration speed

V

CR

Range: 0 ~ +2,147,483,647 unit*1 (10 ~ 200K PPS pulse

transfer value) *2, factory setting: 1,000 unit*1

#16 H’41A0 9 R/W

The number of PG0

in zero return mode N

Range: 0~+32,767 PLS, factory setting: 0 PLS

#17 H’41A1 9 R/W

The number of pulse

in zero return mode P

Range: -32,768 ~+32,767 PLS, factory setting: 0 PLS

#18 H’41A2 9 R/W

Zero return mode

b0: Zero return mode, b1: detect DOG falling-edge in zero

return mode

bit #

Description

0

b[0]=0: normal mode, b[0]=1: override mode

1

b[1]=0: DOG falling-edge detecting is on in zero return mode. b[1]=1: DOG falling-edge detecting is off in

zero return mode.