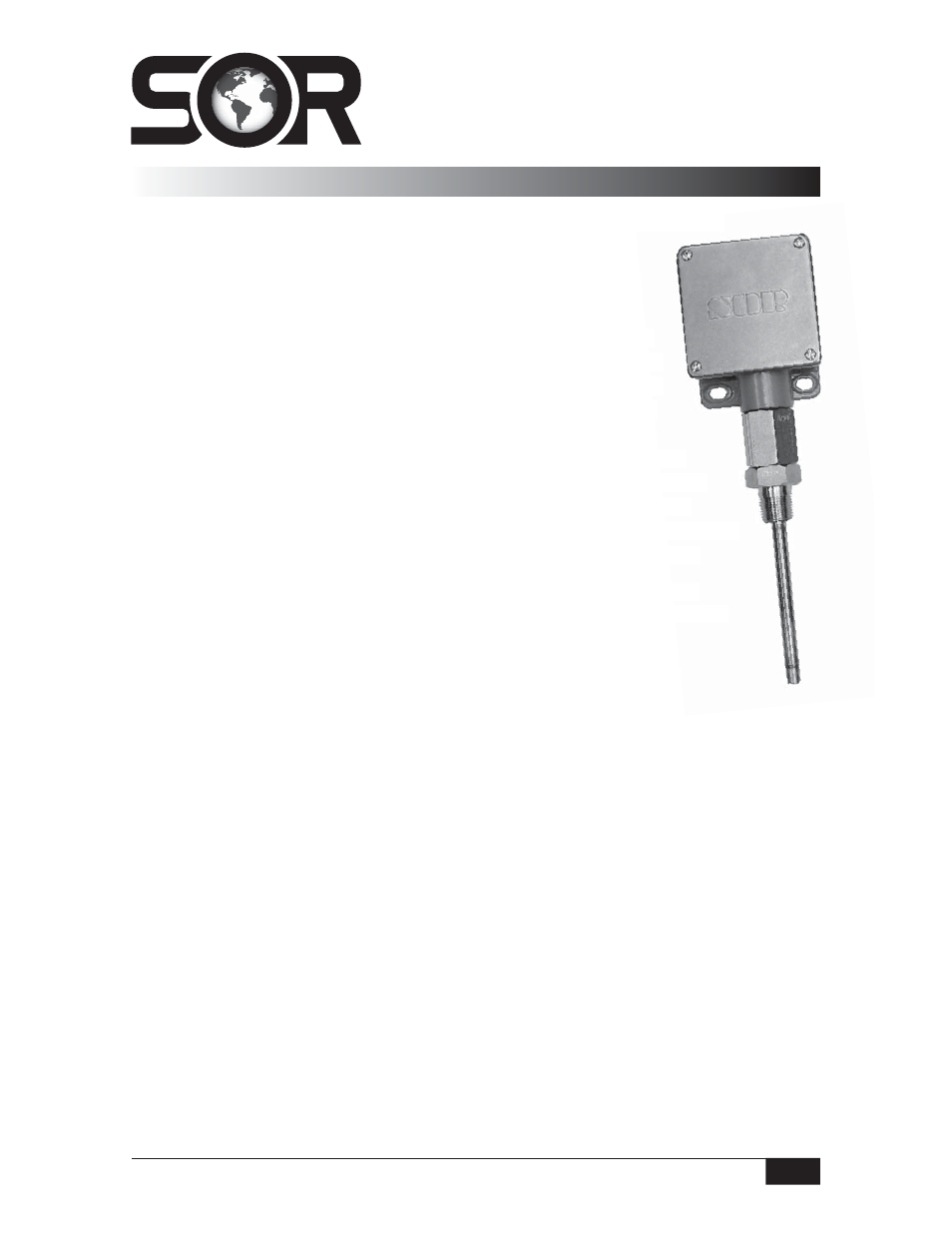

SOR RT Nuclear Qualified Temperature Switch User Manual

Temperature switch with terminal block, Nuclear qualified, General instructions

Form 1473 (05.13) ©SOR Inc.

1/4

The SOR

®

nuclear temperature switch utilizes a SAMA Class II thermal system.

NOTE: This type of system requires that the entire length of the

sensing bulb be exposed to the temperature being measured.

In considering the validity of a measurement, remember that

temperature-sensing devices respond only to the temperature that they

experience. It may be considerably different from the temperature one is

attempting to measure if the sensor is of improper size or configuration,

or if the sensor is not adequately coupled thermally to the media whose

temperature is being measured. The calibration procedures given

below will assure accurate and repeatable measurement of the set points of

SOR temperature switches. If the switch is normally mounted in a thermowell,

consideration should be given to the effect this may have on the accuracy of

the switch. It is recommended that a heat transfer paste or oil be used to thermally

couple the sensing bulb to the thermowell, both in service and during testing.

Nuclear Qualified

Temperature Switch

with Terminal Block

General Instructions

NOTE: If you suspect that a product is defective, contact the factory or the SOR

Representative in your area for a return authorization number (RMA). This product

should only be installed by trained and competent personnel.

Design and specifications are subject to change without notice.

For latest revision, go to sorinc.com

mal system.

y

is

n,

e

ts of

mowell,

cy of

o thermal

l

ly

sting.

SOR

product

Recommended temperature measurement procedure for switches used to sense

temperatures of liquids and steam with set points below 200°F:

1. Use a liquid bath (ethylene glycol, water, oil, etc.) with sufficient circulation to provide a

uniform bath temperature and efficient transfer of heat from the liquid to the sensing bulb.

2 . Fully submerge the sensing bulb into the bath. Direct-mount sensing bulbs should be

submerged up to the bottom of the process connection threads.

3. Locate the tip of the temperature measuring standard (thermocouple, RTD, etc.) at the

mid point of, and adjacent to the sensing bulb.

4. Locate the sensing bulb and temperature measuring standard so that they do not touch

the sides or bottom of the bath or the heating and cooling coils.

5. When the bath temperature is within 3°F of the set points, it is recommended that the

temperature of the bath be changed at a rate of 0.1°F per 5 seconds or slower.

6. The minimum and maximum bath temperatures that the switch sees during testing

should be duplicated each time the switch is tested. It is recommended that the

temperature of the bath be changed from the normal operating temperature to the

critical set point and back to the reset. Do not overshoot the critical set point if the

switch is going to be cycled more than once during the test.