Troubleshooting – SOR RF Continuous Level Transmitter User Manual

Page 12

12/16

Form 837 (05.13) ©SOR Inc.

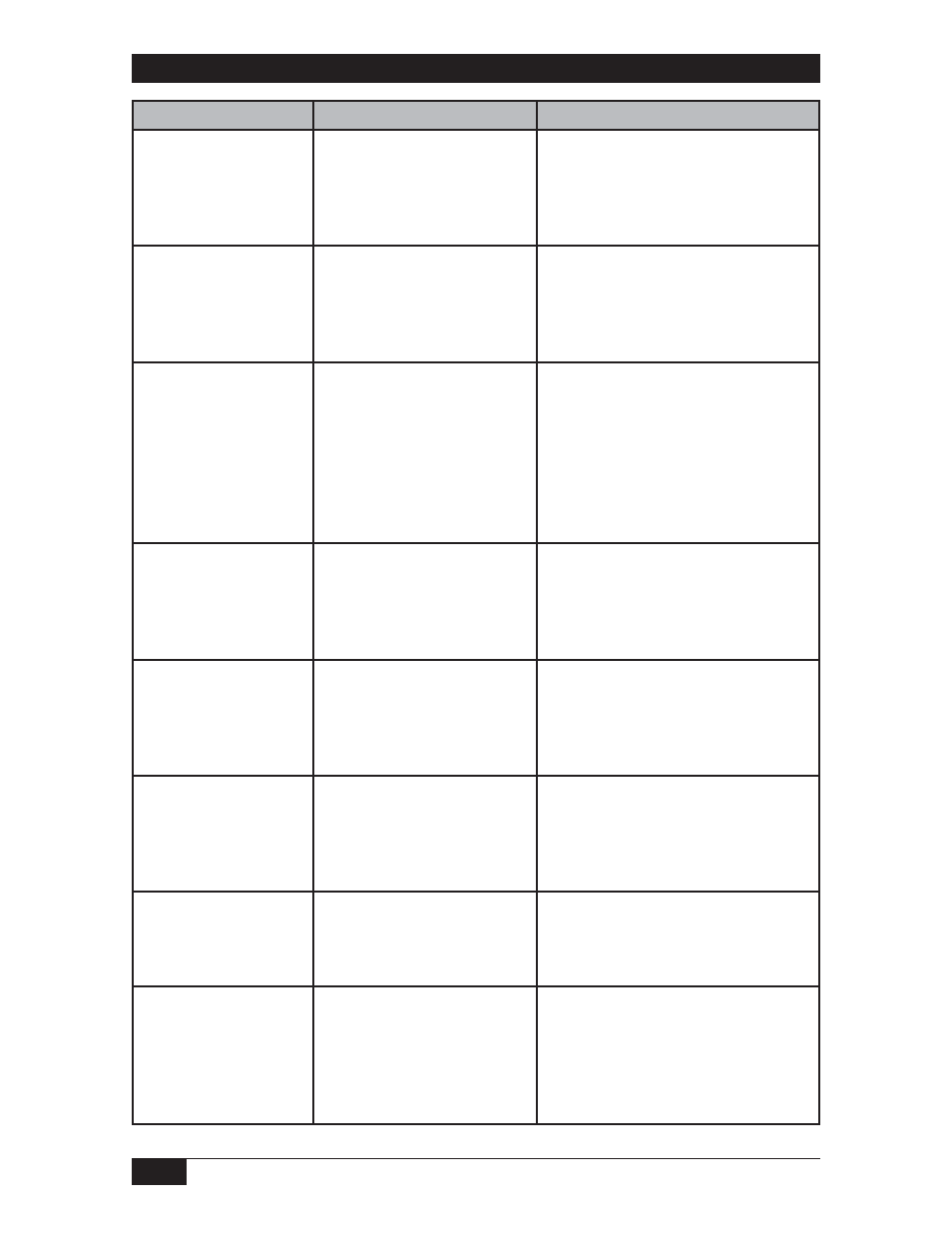

Troubleshooting

Symptom/Problem

Possible Cause

Corrective Action

Not current in the loop

1. Power supply turned off

2. Improper wiring at TB1

3. Excessive loop resistance

1. Check power supply

2. Check electrical connections,

figure 4

3. Reduce loop resistance or adjust

power supply

Zero point cannot be

set to 4.00mA at low

level

1. Fine zero incorrect

2. Probe capacitance greater

than 500pF when coarse

ZERO switch #4 is closed (all

other switches open)

1. Check calibration

2. Use smaller diameter probe or

replace bare probe w/insulated probe

or locate probe farther from the

vessel wall or consult the factory

Span point cannot be

increased to 20mA at

high level

1. Insufficient probe

capacitance

2. Excessive loop resistance

3. Incorrect calibration

1. Increase probe diameter or use

probe w/higher dielectric insulation

or locate probe closer to vessel wall

or install a stilling well or consult the

factory

2. Reduce loop resistance or adjust

power supply

3. Check calibration

Span point cannot be

decreased to 20mA at

high level

1. Low probe resistance to

ground

2. Probe capacitance greater

than 2,000pF

1. Consult the factory

2. Use a smaller diameter probe or

replace bare probe w/insulated probe

or locate the probe farther from the

vessel wall

Transmitter output is

20mA or greater when

the vessel is not full

1. Incorrect calibration

2. Probe shorted to ground

3. Material build-up on probe

1. Recalibrate

2. Replace the probe

3. Clean probe and replace or

possible misapplication, consult

the factory

Erratic transmitter

output

1. Turbulent process

2. Radio frequency

interference

3. Probe moving within the

vessel

1. Install a stilling well

2. Install RFI/EMI filters

3. Improve probe anchoring

Drifting transmitter

output

1. Process material

properties are changing

2. Probe insulation is eroded

3. Transmitter malfunction

1. Consult the factory

2. Verify probe integrity

3. Consult the factory

Non-linear output

1. Extreme material build-up

2. Non-parallel surfaces near

the probe

3. Conducting liquid in an

ungrounded vessel, eg:

fiberglass tank

1. Consult the factory

2. Mount the probe in a better

location or install a stilling well, or

install a probe with a ground rod

3. Connect earth ground to

instrument ground