SOR 1530 Pneumatic Level Switch User Manual

Page 2

2/4

Form 439 (04.13) ©SOR Inc.

Before Installing the Level Switch

Inspect the unit for any shipment damage.

Check for mechanical clearance. The float must move freely throughout its stroke inside

the vessel.

Use an acceptable thread compound to ensure a leak free fit and avoid thread galling

when installing the unit into the vessel.

The unit may be mounted in any of the following installation arrangements:

2” NPT full or half coupling

3” NPT full coupling (Use in conjunction with 2 x 3” NPT bushing.)

Optional flanged mounting

Optional chamber mounting

Clean dry air or gas must be used as the supply media to avoid plugging critical internal

restrictions and nozzles.

SUPPLY PRESSURE RANGE: 20 TO 60 PSIG

Installation

Connect the supply line to the 1/8” NPT connection stamped Supply. Do not use pipe

compound on the first two threads on pneumatic fitting. The supply media must be

filtered and oil free. Air is the usual media; however, any dry filtered gas can be used.

Connect the output port stamped Output to the unit to be controlled.

NOTE: If the controlled device has a volume of less than 15 cubic inches, the small volume may

cause the output to fl uctuate. The addition of output volume will stop this fl uctuation.

VENTING CAUTION: Note the position of the vent connection on the body. It must

be positioned on a horizontal axis either on the right or the left side of the body.

This connection must not be plugged. It is used for either local atmospheric

venting or remote venting through a suitable line run to the designated venting

area. Supply or Output connections must not be connected to the Vent port.

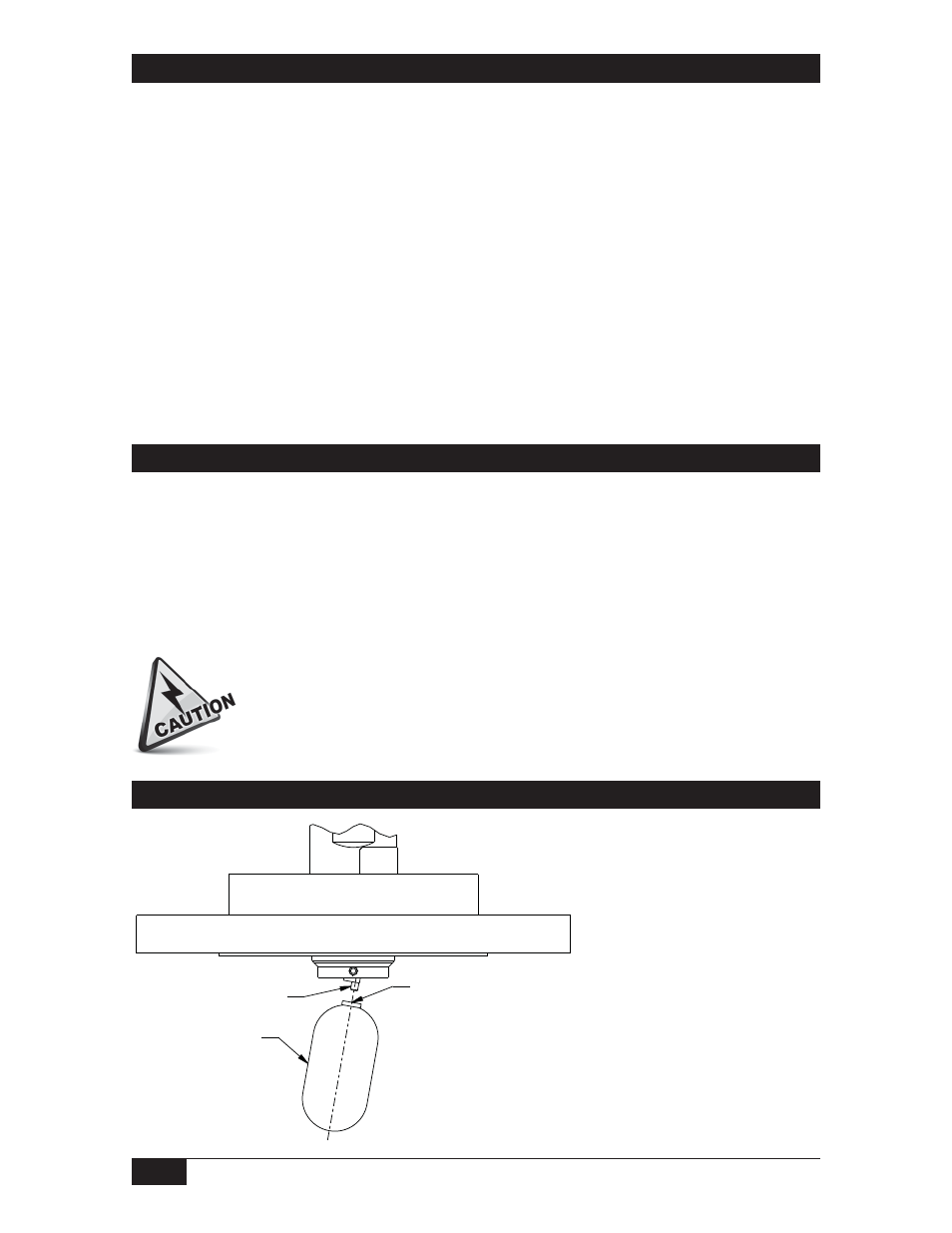

Float Attachment

APPLY TWO DROPS

LOCTITE 271 INSIDE

THREADED HOLE

OF FLOAT

FLOAT

SET SCREW

Place two drops of Loctite

271 inside the threaded

hole of the float.

Thread the float onto the set

screw and hand-tighten.

Linear = mm/inches

Drawing 0390747

NOTE: Do not remove the set

screw as it secures the pivot

arm to the shaft.