SOR High Static Operation User Manual

Page 2

2/12

Form 391 (01.13) ©SOR Inc.

Process Connection

The high pressure side (marked Hi) has two 1/4” NPT(F) process connections. The

low pressure side (marked Lo) also has two 1/4” NPT(F) process connections. For

optimum performance, bleed the air or liquid from the switch with ports aligned

vertically before placing the switch into service.

Connect the liquid process to the lower ports to bleed gasses from the switch.

Connect the gaseous process to the upper ports to bleed liquid from the switch.

The switch may then be oriented in any position for switching.

When the process has entrained particles or is considered dirty, both upper and lower

connections may be used to create a flushing system to prevent buildup against the

diaphragm/piston assembly. Should a pair of process connections be plugged, ensure

that plugs are tightened for a leak-free fit.

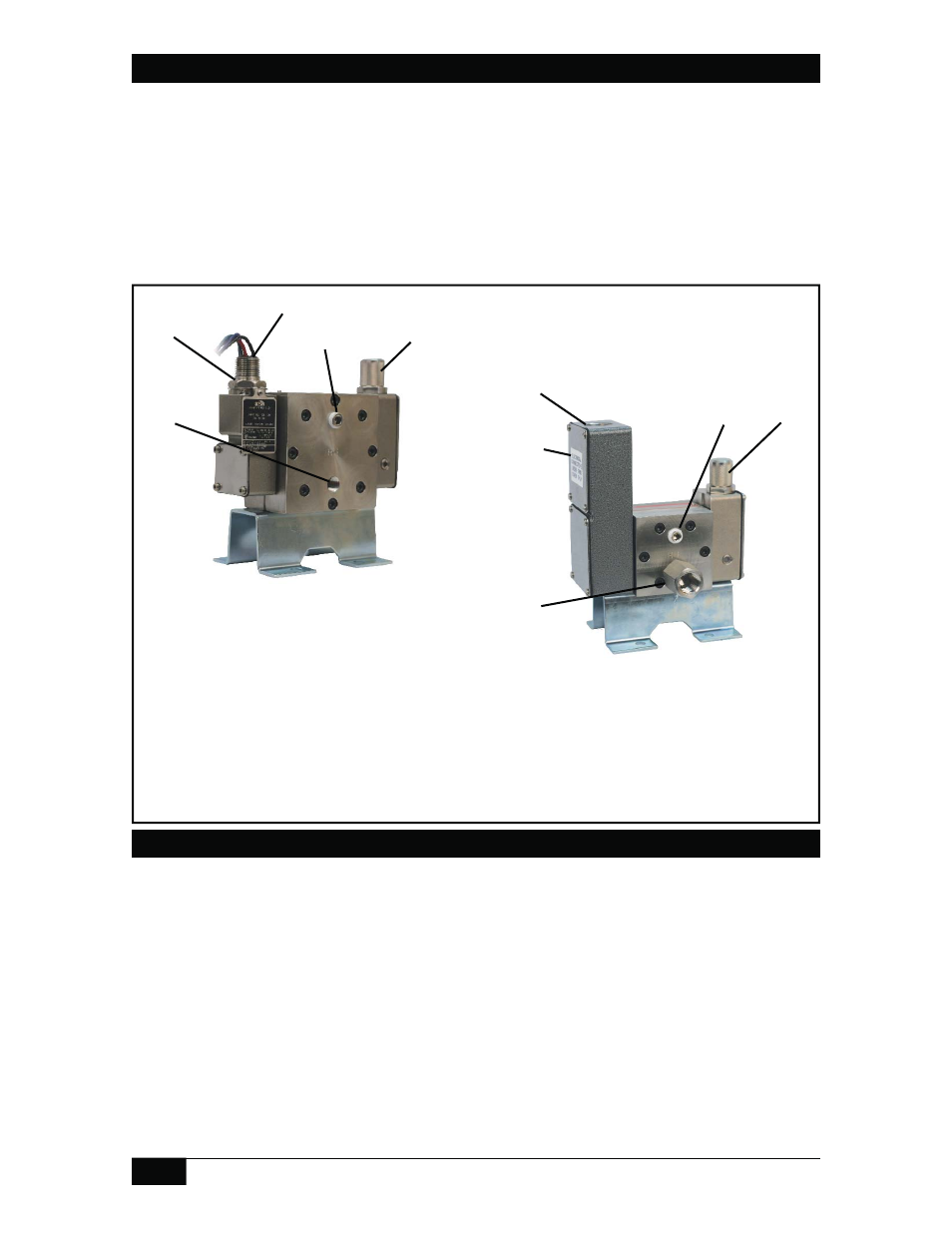

Explosion Proof – AD Housing

AD - ATEX Certified EEx d IIC - CL Accessory

Weathertight — W1 Housing

Knurled cap over Set Point adjustment

Hi side gaseous process connection 1/4” NPT(F)

Hi side liquid process connection 1/4” NPT(F)

Hermetically sealed switching element capsule (18”, 18-AWG wire leads)

1/2” NPT(M) electrical conduit connection

3/4” NPT(F) electrical conduit connection

Weathertight switching element housing (terminal block under cover)

103 Differential Pressure Switch Diagrams

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration.

Form 1538 (03.12) ©2012 SOR Inc.

(F)