SOR Single Diaphragm Weatherproof Differential Pressure Switch with Terminal Block Connections User Manual

Page 5

Form 506 (01.13) ©SOR Inc.

5/12

For Critical Set Point on Increasing Differential Pressure

Connect the continuity test lamp or ohmmeter across the C - Common and NO -

Normally Open switching element / contacts.

Close the bleed valve(s), open the equalizer valve and raise pressure equally on both HI

and LO sides to the static pressure that the differential pressure switch will see under

normal operating conditions.

With static pressure stable, close the equalizer valve to isolate the HI side from the LO

side.

Keeping high side pressure steady, slightly open the LO side bleed valve to reduce the

LO side pressure (increase differential pressure) until desired differential pressure set

point appears on indicator. Close bleed valve to stabilize differential pressure. Check the

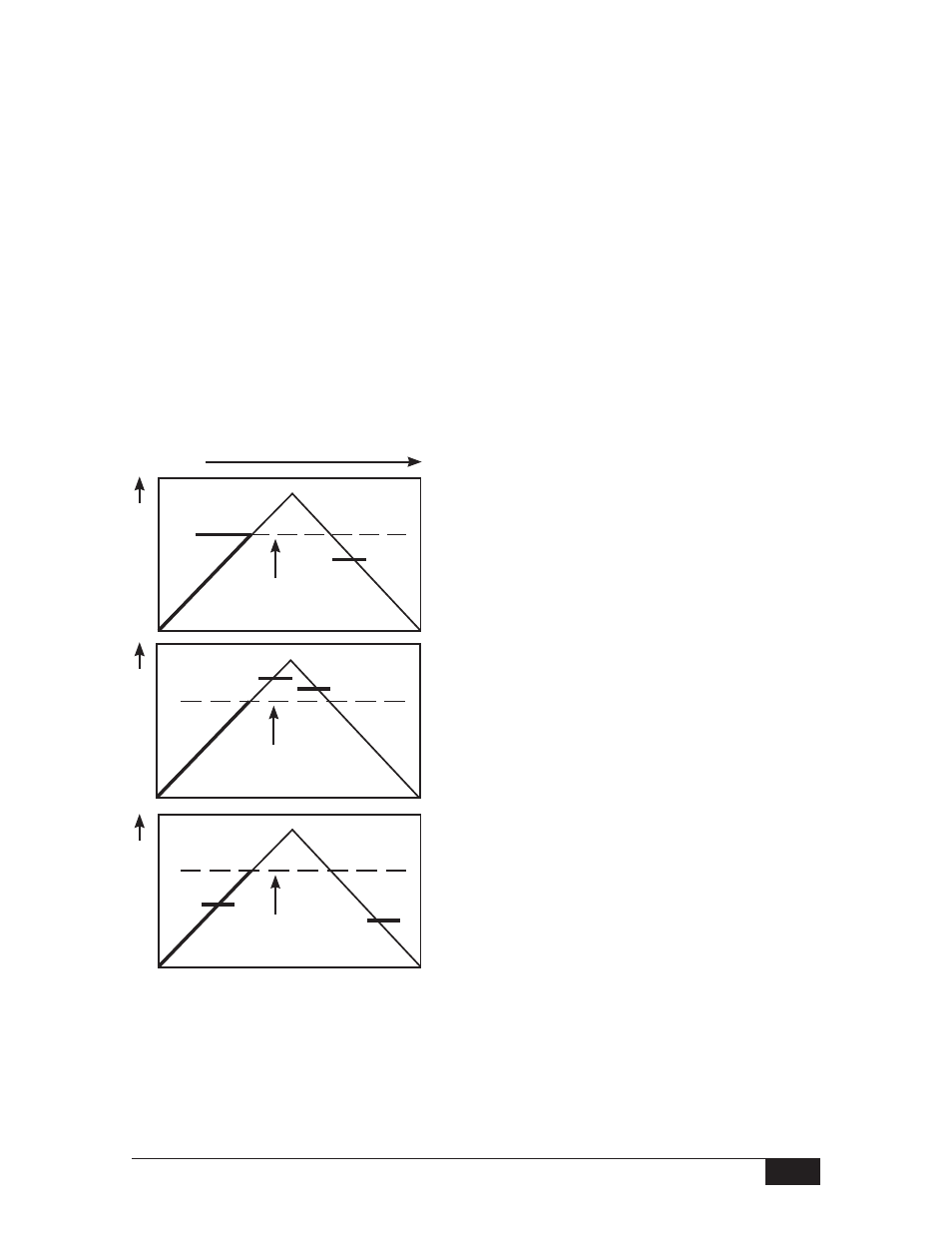

status of the electrical contacts against the following differential pressure trend graphs.

Follow the instructions under the graph that matches the status of the contacts.

If contacts make precisely at critical increasing

differential pressure set point, repeat Steps

-

as desired to verify calibration.

Calibration is complete.

If contacts are open when critical increasing

differential pressure is reached, turn set point

adjustment counterclockwise (out) until

contacts make. Repeat Steps

-

.

If contacts are closed when critical increasing

differential pressure is reached, turn set point

adjustment clockwise (in) until contacts break.

From this point, turn set point adjustment

counterclockwise (out) until contacts make.

Repeat Steps

-

.

Contacts Open - Set Point Too High

Set Point OK

Contacts Closed - Set Point Too Low

0 Time

Differential Pressure

Break

Make

Critical

Increasing

Set Point

Critical

Increasing

Set Point

Make

Break

Break

Make

Critical

Increasing

Set Point

See SOR Form 468 for reference dimension drawings. For certified dimension drawings

contact factory.

Differential Pressure

Differential Pressure