Envelope sealing problems, Envelope sealing problems -3 – Pitney Bowes DM875 Series User Manual

Page 179

DM825™ and DM875™ Series Digital Mailing System Operating Guide

SV62200 Rev. C

10-3

Envelope Sealing Problems

Description

Possible Causes

Solution

Envelope(s) not seal-

ing or not sealing

properly

No E-Z Seal® Sealing Solution in

the bottle, or bottle is placed incor-

rectly.

Remove the E-Z Seal® solution bottle and refill

or reposition the bottle.

Refer to the E-Z Seal® Maintenance section in

Chapter 9

of this guide.

Moistener brush is dirty or worn.

Replace or clean the moistener brush. Refer to

the Cleaning or Replacing the Moistener Brush

section in Chapter 9 of this guide.

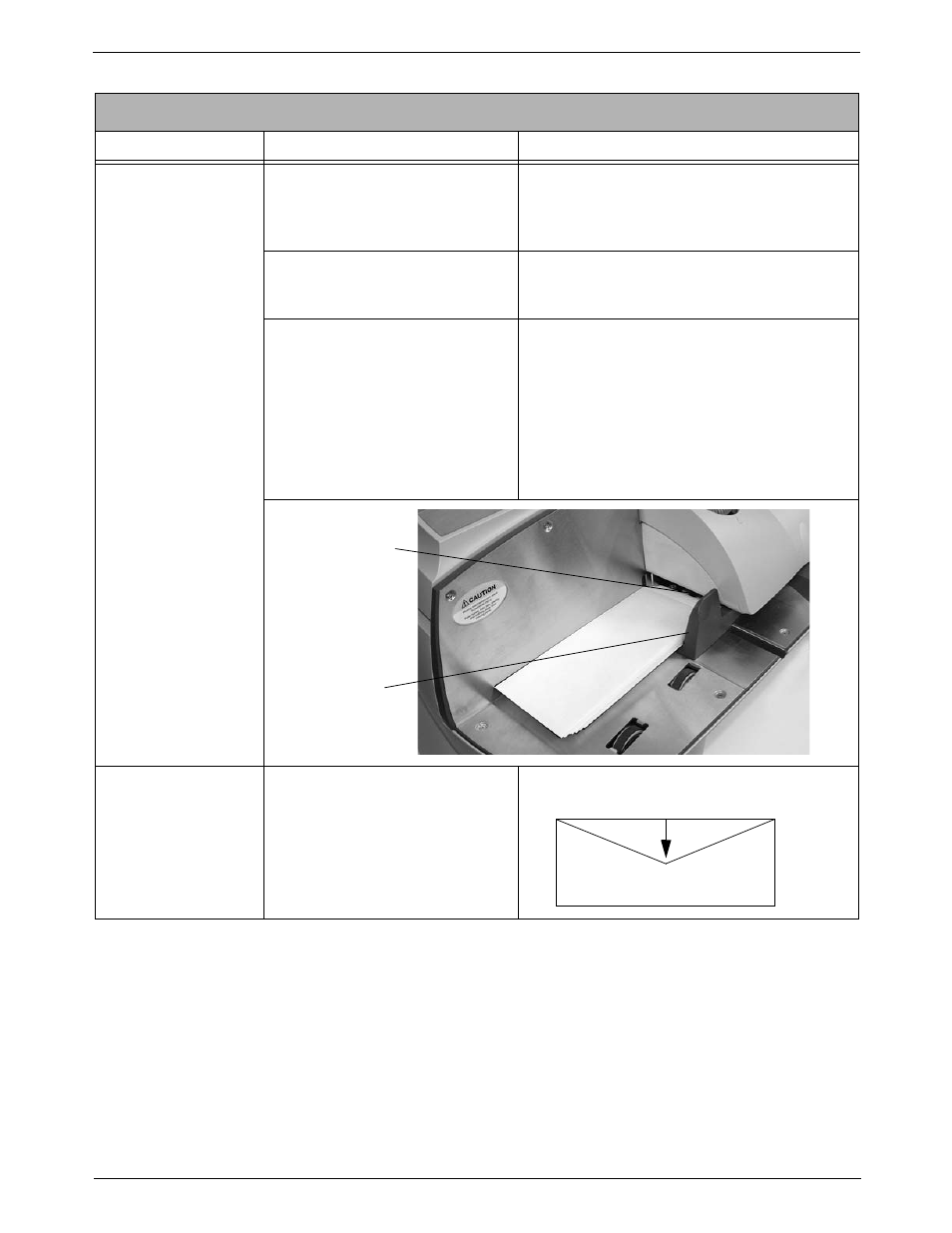

Envelopes are not positioned on

the feed deck correctly, or side

guide is out too far.

Place envelopes with the flap down on the feed

deck against the rear wall.

Make sure the envelopes are pushed far

enough so that they cover the feed sensor on

the rear wall. Push the side guide close to the

envelope or stack of envelopes but not to the

point where it is touching the envelopes. Leave

about 1/16" clearance (the thickness of a

dime).

Envelope(s) not seal-

ing or not sealing

properly

Envelope flap dimensions are not

within the acceptable range.

Use envelopes with flap depths between 1"

and

3 7/8"

(25.4 mm and

98.4 mm

).

Feed Sensor

Side Guide

Flap Depth