Sprayer operation 25 – PermaGreen Triumph Spread-Only User Manual

Page 29

IMPORTANT: The Sprayer requires periodic calibration and

adjustment to verify the sprayer pattern and to verify the correct

product delivery rate because improper application of products can

damage turf or reduce the efficacy of applied products.

IMPORTANT: Check and adjust Broadcast Spray pattern daily,

prior to treating each lawn, and as needed to verify that the nozzles

are properly aligned and spraying properly.

IMPORTANT: Whenever you change products or rates of

application and at one-month intervals, or more frequently during

heavy use, verify that calibration is still valid. Adjust as necessary.

IMPORTANT: You should regularly compare the amount of

product used to the number of square feet covered.

IMPORTANT: Use caution when spraying near desirable

vegetation or painted surfaces to avoid damage.

IMPORTANT: Use caution when spraying in windy conditions

to avoid damage.

IMPORTANT: The Triumph spray system is designed to apply

Low Volume spray solutions at the application rate of

approximately 1 QUART PER THOUSAND SQUARE FEET (0.95

L / 93 m

2

). An optional kit is available with nozzles sized to apply

approximately ½ GALLON PER THOUSAND SQUARE FEET (1.9

L / 93 m

2

). Products that require higher application rates than these

are not suitable for use in the Triumph.

IMPORTANT: The Triumph spray system is not well equipped

to apply water insoluble products and such products may clog the

spray system.

IMPORTANT: It is recommended that a compatibility jar test be

conducted prior to mixing any product or products in Triumph.

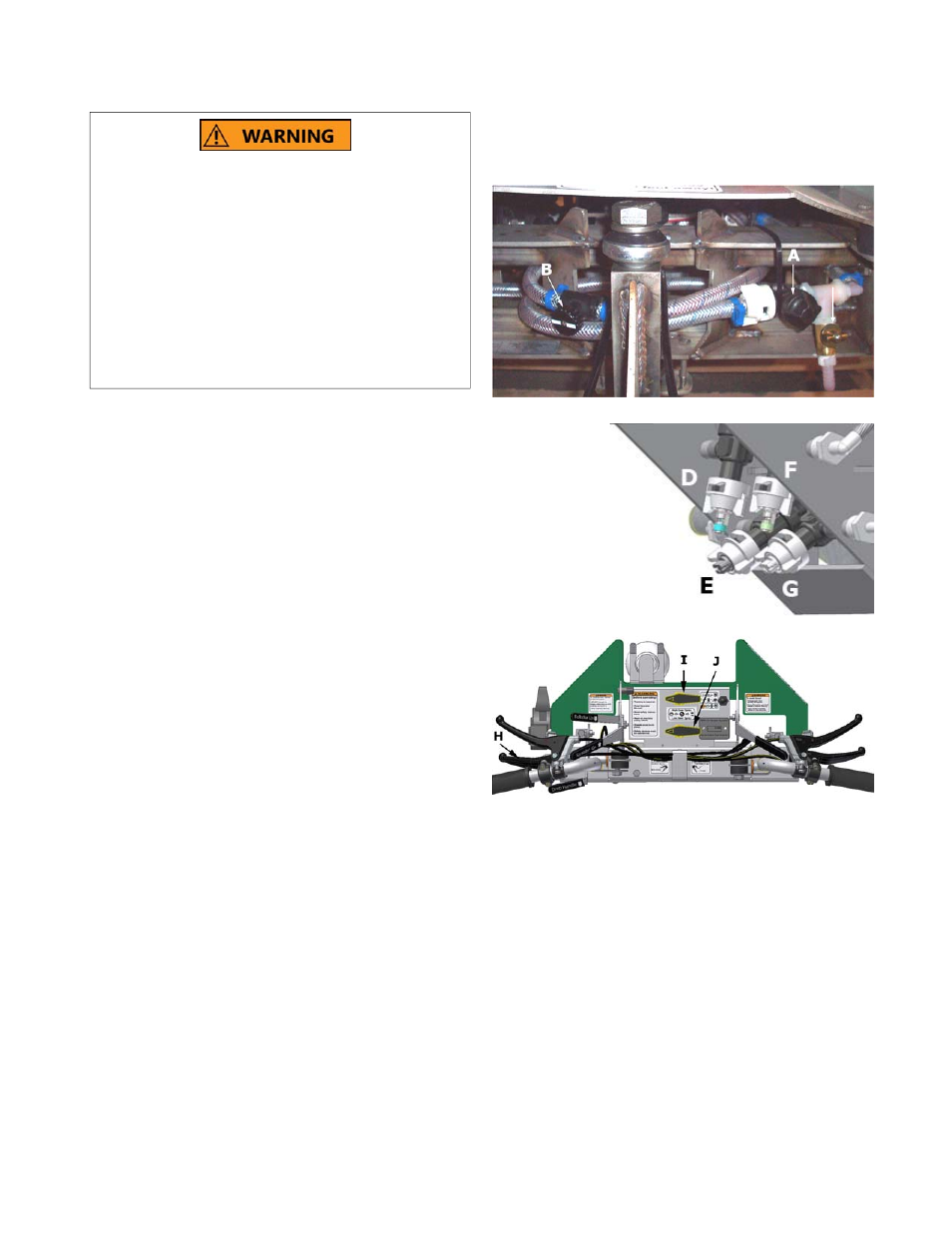

Description of Sprayer features, controls, and operation

The spray pattern and spray rate are controlled by the engine

speed, pump pressure, and the nozzle orifice. Referring to FIGURE

14: A Pressure Unloader Valve (A) at the lower right rear of the

front frame controls pump pressure. There is a Suction Shutoff

Valve (B) located at the lower left rear of the front frame. The Drain

Valve (C) can be used to flush the spray system, drain the tanks or

fill the Spot Sprayer bottle (included). A Strainer (not shown) is

located inside each Tank. The Tanks are connected together by

common Suction and Return flow plumbing to provide a total

capacity of 12 U.S. GALLONS (45.4 liters). NOTE: The Triumph is

not capable of selectively drawing from only one Tank.

Referring to FIGURE 15: There is a pair of low drift nozzles

(broadcast (D) & trim (E)) for use while in LOW GEAR, and a

second pair of low drift nozzles (broadcast (F) and trim (G)) for use

in HIGH GEAR. [If the Half Gallon Nozzle Kit is installed, the LOW

GEAR Broadcast Nozzle is replaced by a second HIGH GEAR

Nozzle and

both are used simultaneously to spray.]

Referring to FIGURE 16: A Spray Lever (H) with lock is mounted

on the

left handle

which allows the operator to spot spray the liquid product while

blanket covering the area with granular product.

Dashboard mounted Spray Selector Valves (I) control which

selects High gear Broadcast and Trim Nozzles. Spray Valve (J)

selects Low gear Broadcast and Trim Nozzles.

The sprayer comes from the factory with standard nozzles sized to

apply approximately 1 QUART (.95 liters) per thousand square feet

((93 m

2

) in either gear whether broadcasting or trimming. [An

optional Half Gallon Nozzle Kit is available to apply approximately

ONE-HALF GALLON (1.89 liters) PER THOUSAND SQUARE

FEET.]

With the 20 PSI Pressure Unloader Valve installed at the factory,

the sprayer has a 7-FOOT effective pattern width and an 11

FEET (3.4 meters) overall pattern width using a single front

mounted broadcast nozzle, as shown in FIGURE 17. The spray

distribution pattern allows the use of a 7-FOOT (2.1 meter)

overlap spreader travel pattern to achieve an even and complete

coverage of the sprayed product on the entire turf area by

overlapping the edge of the last spray pattern approximately 2

FEET (.61 meter). Using a trim nozzle provides an even

finished distribution over a spray pattern of 6 FEET (1.82 meters)

on the surface being treated.

Sprayer Operation

25

Pesticide Safety

The improper use, handling, application, and disposal of pesticide

products applied by this machine may cause death or serious inju-

ry.

Read and follow product label and Material Safety Data Sheet

(MSDS) precautions for handling, mixing, applying, and dispos-

ing of pesticides applied by this machine. Some materials may

present health hazards that will require the use of Personal

Protective Equipment (PPE). Always wear required PPE.

Keep required Personal Protection Equipment (PPE) available

for use by the operator or mechanic.

Keep pesticide labels and MSDS available for the operator or

mechanic.

20

FIGURE 16, Sprayer Controls

FIGURE 15, Nozzles

FIGURE 14, Unloader and Shutoff

C