Spreader operation 22 – PermaGreen Triumph Spread-Only User Manual

Page 26

Recheck opening and adjust if necessary.

Calibrate LOW GEAR rate setting;

Make initial LOW GEAR adjustments using the Black LOW

GEAR Rate Adjuster Knob (FIGURE 10.2-A) on the

Handlebar

Once your Pre-Calibrated LOW GEAR setting is adjusted,

reposition the stop bolt (FIGURE 10.2-C) against the Rate

Adjuster Knob (FIGURE 10.2-A) to lock in your Pre-set

location. A 5/32” Allen wrench is required.

Recheck opening and adjust if necessary.

Deflector operation:

To raise the Deflector (not shown) out of the path of the

granular spread pattern, move the Deflector Lever (A)

forward.

To lower the Deflector and interrupt the granular spread

pattern to the right of the spreader, pull the Deflector Lever

rearwards.

Third-hole pattern adjuster operation when using the Deflector:

To close the Third-hole Adjustment Plate when lowering the

Deflector, pull the Third-hole Lever rearwards.

To open the Third-hole Adjustment Plate (not shown), push

the Third-hole Lever forward.

Using the Third-hole pattern adjuster to balance the granular

spread pattern.

To reduce the amount of granular material spread towards

the right side of the machine, move the Third-hole Lever

rearward to partially close the Third-hole Adjuster Plate.

NOTE: The gray sliding Memory-Lock should be

positioned to secure the Third-hole Lever at that setting.

The Lever pops into the Memory-Lock to hold it in place.

The Lever may then be used to close the Third-hole

Adjuster Plate and return to your pre-set Memory-Lock

position.

To increase the amount of granular material spread towards

the right side of the machine, move the Third-hole Lever

forward to increase the opening of the Third-hole Adjuster

Plate.

Spreader Operation

NOTE: For proper spreading the engine RPM (measured with

the machine in NEUTRAL) MUST be maintained at 3,450 RPM,

regardless of whether the machine is in HIGH or LOW GEAR. If

engine RPMs are too low the spread width will be too narrow for

effective spreading. If too high, the spread width will be too wide.

NOTE: For proper spreading the spreader MUST be calibrated

(Refer to Spreader Calibration in this section).

For best results, It is recommended that products be applied using

one of the following methods:

Method 1: Make edging pass followed by parallel passes.

First make a trim-pass, edging around the perimeter of the

property and any ornamental beds etc.

Pull the Deflector Lever to the rear to lower the Defector

while simultaneously pulling the Third-hole Lever rearward

to close the Third-hole Adjuster Plate and reduce the spread

width by cutting off the material on the right side.

Select the appropriate gear for the terrain and turf conditions.

Use LOW GEAR on inclines, slopes and/or hills and in tight

areas.

Use HIGH GEAR on level and open areas.

Set the Rate Adjustment Knob to the pre-calibrated rate for the

gear selected.

Pull the Throttle Lever to accelerate while simultaneously

pushing the Hopper Lever forward to open the spreader and

permit granular material to flow from the Hopper.

Make the trim- pass keeping the right side of the granular

spread pattern inside the edge of the sidewalk, ornamental

beds, etc.

When it is necessary to stop the machine, simultaneously

release the Throttle Lever and pull the Hopper Lever to the rear

to stop the flow of granular material.

After making the trim-pass, stop and push the Deflector Lever

and the Third-hole Lever forward to return the Deflector to the

up position and the Third-hole Adjustment Plate to the broadcast

setting.

Change gears if desired. NOTE: Return the Rate Adjustment

Knob to the pre-calibrated rate for the gear selected.

Make a header-pass following the path of the trim-pass and

keeping the right side of the granular spread pattern inside the

edge of the sidewalk, ornamental beds, etc.

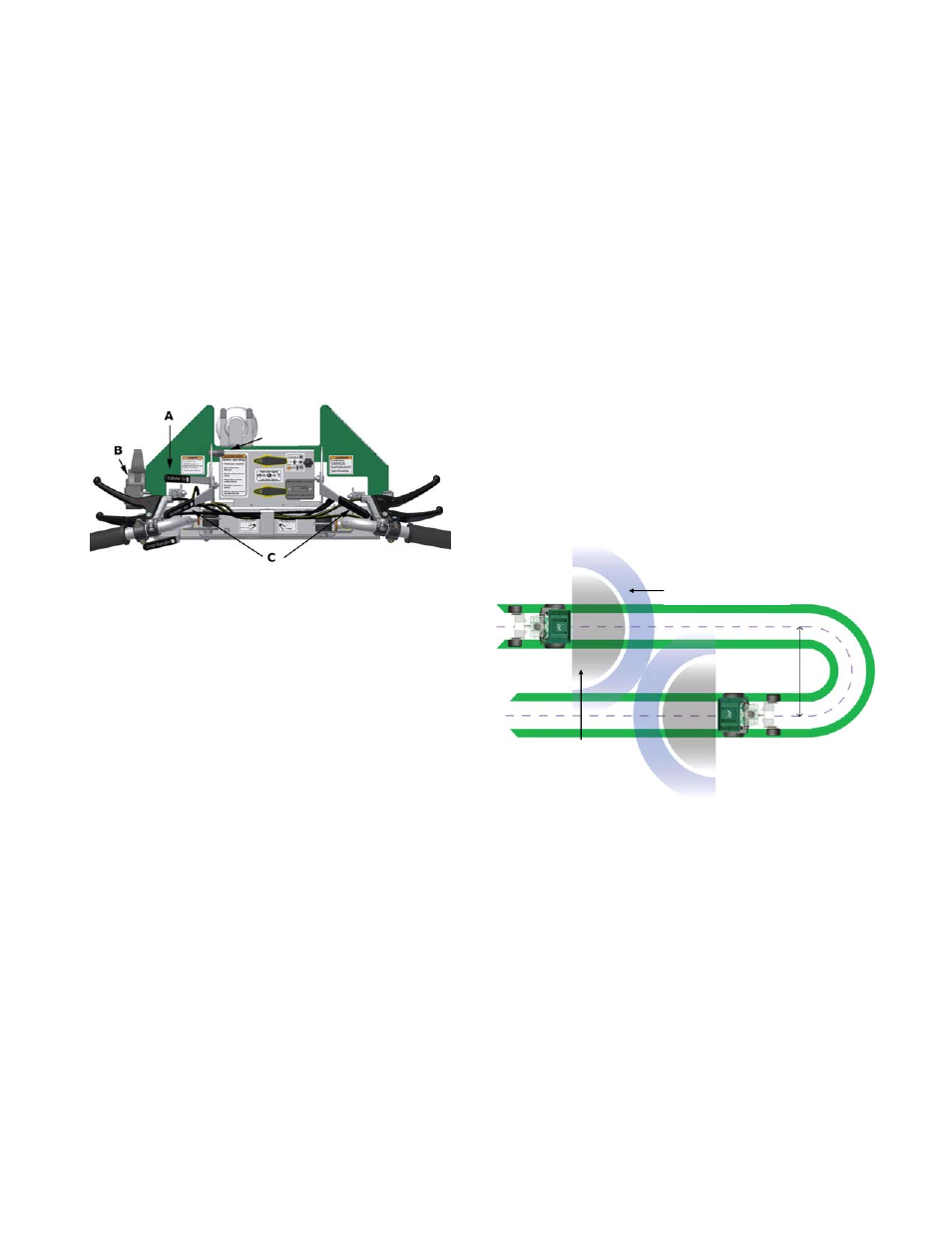

Referring to FIGURE 11, fill the center of the lawn by making

parallel passes.

Turn on 7-FOOT centers. NOTE: The edge of the spread

pattern of most granular materials will fall between the

wheel marks of a preceding pass.

The first pass should overlap back to the centerline of your

wheel tracks of one of the header-pass.

As you enter the fertilized area of the header-pass, shut off

the hopper as you make a 180-DEGREE turn.

Quickly open the hopper as you come out of the turn

heading back in the opposite direction with the fertilizer

overlapping to the center of your last parallel pass.

Repeat this process throughout the rest of the lawn.

Method 2: Make a trim-pass and header-pass as in the previous

section. Then continue filling in the center making descending

spiral passes around the periphery ending in the center. This

method helps compensate for an unbalanced pattern distribution

because the right side pattern always overlaps the left side pattern.

Either method may be used simultaneously with the spray features

on the machine. When trim-spraying the edging pass use the

appropriate trim nozzle for the gear selected and spray as needed.

When Broadcast-spraying the center area use the appropriate

Broadcast nozzle for the gear selected and spray as need

Spreader Calibration

Adjustment of the spreader establishes the correct spread pattern.

The center discharge hole establishes the center of the pattern.

The right-hand discharge hole (as viewed from the Operator

position) establishes the spread pattern on the left-hand side. The

left-hand discharge hole establishes the spread pattern on the right

-hand side. Calibration establishes the correct application rate and

balances the spreader pattern.

Spreader Operation

22

FIGURE 11, Spreader Passes

Spread Pattern

Spray Pattern

Effective Spread

Width, Example:

7-8 Foot