Spreader operation 23 – PermaGreen Triumph Spread-Only User Manual

Page 27

Verify that the spreader discharge holes are closed.

If the spreader discharge holes are not completely closed, adjust

the length of the control cable running from the controls on the left

handlebar down the handle to the outer hopper control plate by

loosening and repositioning the locknuts.

If you did not purchase a calibration kit with your Triumph, obtain

the following materials:

Eleven collection pans, 3 to 4 INCHES (8 to 10 centimeters)

high and about 1 FOOT (0.3 meter) square (i.e., aluminum

roasting pans)

A clear graduated tube, 1/2-Inch (13 millimeter) internal

diameter, 3 to 4 INCHES (8 to 10 centimeters) tall (to act as a

graduated cylinder for measuring the collected fertilizer pellets)

Use a thin-tipped permanent marker to mark the tube at

QUARTER-INCH (6 millimeter) increments all the way up the

tube.

Clear, graduated ONE QUART (one liter) measuring cup

Stop watch or wristwatch.

This owner’s manual, and a pencil to record your collection

amounts.

Example Calibration procedure. IMPORTANT: The actual

settings for the fertilizer you are using will be different.

Establish the spreader Rate adjustment and calibration adjustment

for a fertilizer to be applied at the rate of 3 POUNDS / 1,000 ft

2

(1.36 Kg / 93 m

2

).

Place the spreader operating lever in the CLOSED position.

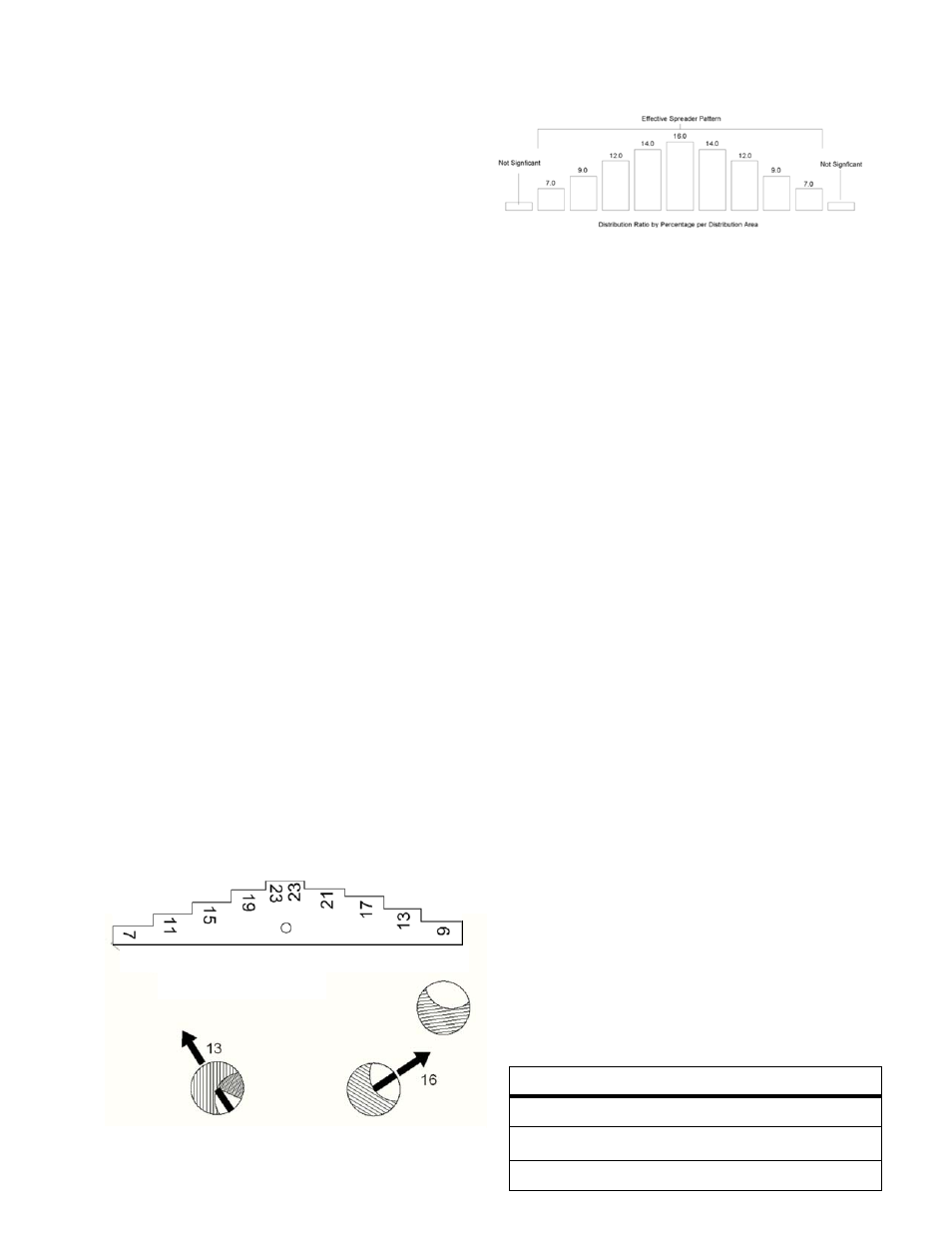

Open the Hopper and using the Calibration Gage (FIGURE 12)

provided with the machine as shown in FIGURE 13, set the

center hole opening to 16. Position the Rate Adjustment Knob

against the Hopper Lever and tighten the knob.

Close and open the Hopper several times and confirm hole

opening.

Adjust Third-hole setting.

Without changing the Rate Adjustment Knob setting, open

the Third-hole and insert the Calibration Gage, orientated as

shown in FIGURE 13, in the Third-hole.

Using the Third-hole Lever, position the Third-hole

Adjustment Plate against the Calibration Gage and position

the Memory-Lock until it pops into the Lever and locks its

position.

Remove the Calibration Gage.

Close and open the Third-hole several times and verify the

Third-hole setting is 13. Readjust as necessary.

Record both the Calibration Gage setting and the Memory-

Lock setting for future use. NOTE: The correct Calibration

Gage setting must be verified from time to time.

The Memory-Lock setting is adequate for reference in the

field, but it must be adjusted to the Calibration Gage during

the Daily machine Servicing.

Determine the effective spread width of the granular product:

Spreader Operation

23

Place 11 calibration pans in a line on two-foot centers on a

paved area such as a parking lot. NOTE: Checking the

effective spread pattern and adjusting the distribution

pattern requires multiple passes over the calibration pans.

This process is done on a paved area to avoid burning the

vegetation by over-fertilizing, and to allow the product to be

collected and reused.

With the material to be spread loaded in the spreader, make

at least three passes from the same direction over the pans

in a path perpendicular to the line of pans while spreading

material.

Pour the contents of the first pan on your far left into the

graduated cylinder or clear tube. Measure and record the

material deposited. Dump the collected pellets back into the

bag or hopper. Repeat this measurement for each pan, one

by one, until all eleven pans are emptied and recorded.

The distribution pattern should be balanced as in FIGURE

13A with a higher amount of product, collected in the

center pan and tapering off equally to both sides. NOTE:

The distribution pattern shown in FIGURE 13A represents

an ideal pattern, which will not be reproducible in the field.

The numbers are used for reference only.

To balance the distribution pattern for the right side, move

the lever as necessary to increase or decrease the opening

in the adjustment hole. Reset the memory lock.

Repeat the passes over the pans and measure the material

deposited in the pans. Readjust the openings as necessary

until the distribution pattern meets the requirements.

The effective spread width is the measured distance

between the left and right pans that contain 50% of the

volume of the center pan.

Record each opening setting for future recalibration.

Determine the Rate Adjustment Knob setting which delivers

the desired amount of fertilizer for the calibrated effective

spreader width (above) for both HIGH GEAR and LOW GEAR

speeds.

Measure AND RECORD the amount of time it takes to

spread 1,000 ft

2

(93 m

2

) of area. NOTE: The machine is

designed to operate at a full throttle engine speed of 3450

RPM while in NEUTRAL. Check engine speed with the

tachometer and adjust to 3450 RPM if needed (see

Adjusting Engine speed to 3450 RPM in the Service

Manual section). Keeping the engine speed constant,

helps insure that the application rate remains constant.

Create a test course based on the effective Spread Width

from the table above. EXAMPLE:

Triumph comes set from the factory to an effective

spread and spray width of 7 FEET, which can be

accomplished by making

7 FOOT center-to-center

parallel passes overlapping approximately 50

PERCENT of the last pass

. Measure a distance

equal to the of 143 FEET (44 meters) over turf. This will

provide a spread area of approximately 1,000 ft

2

(93

m

2

). The effective material spread width for many

products is 7 FEET; therefore, 7 x 143 = 1,001 ft

2

(93

m

2

). NOTE: If your calibrated effective spread width

is 8 feet, you will use 8 x 125 = 1000 ft

2

as the basis for

Length of a 1,000 Square Foot calibration course

Effective Spread Width

Length of Course

7

143

8

125

FIGURE 13A, Spread distribution

FIGURE 13, Spreader Setting

FIGURE 12, Calibration Gauge