Installation, Pressure and temperature limits, A1761hc3 400/415v 3-phase "y" slave box control – Parr Instrument Series 4558 User Manual

Page 9

4555 - 58 Series

5G & 10L Pressure Reactors

- 8 -

INSTALLATION

Pressure and Temperature Limits

The working pressure and temperature at which any reactor or pressure vessel can be

used will depend upon the design of the vessel and the materials used in its construction.

Since all materials lose strength at elevated temperatures, any pressure rating must be

stated in terms of the temperature at which it applies. The standard material of construction

for Parr Instrument Company is Type 316 Stainless Steel.

Limits for vessels made of other materials and for other operating temperatures can be

obtained from Customer Service. No attempt should be made to increase these limits by

making alterations or by substituting components which are not recommended by the Parr

Instrument Company. It must also be understood that lower pressure and temperature limits

may be required for modified reactors and for vessels made of special alloys.

Limits for vessels will be determined by the physical characteristics of the vessel material

and will be prescribed on an individual basis.

Temperature and pressure limits are also affected by the physical properties and

temperature limits of the gaskets and seals used in the vessel, and by any valves, gages or

other fittings attached to the vessel. Obviously, the safe operating pressure of any system

can be no higher than that of its lowest rated component.

All Parr reactors show the maximum safe operating pressure and temperature imprinted

on the cylinder.

The working pressure and temperature in these five gallon and ten liter reactors must not

exceed the following maximum limits:

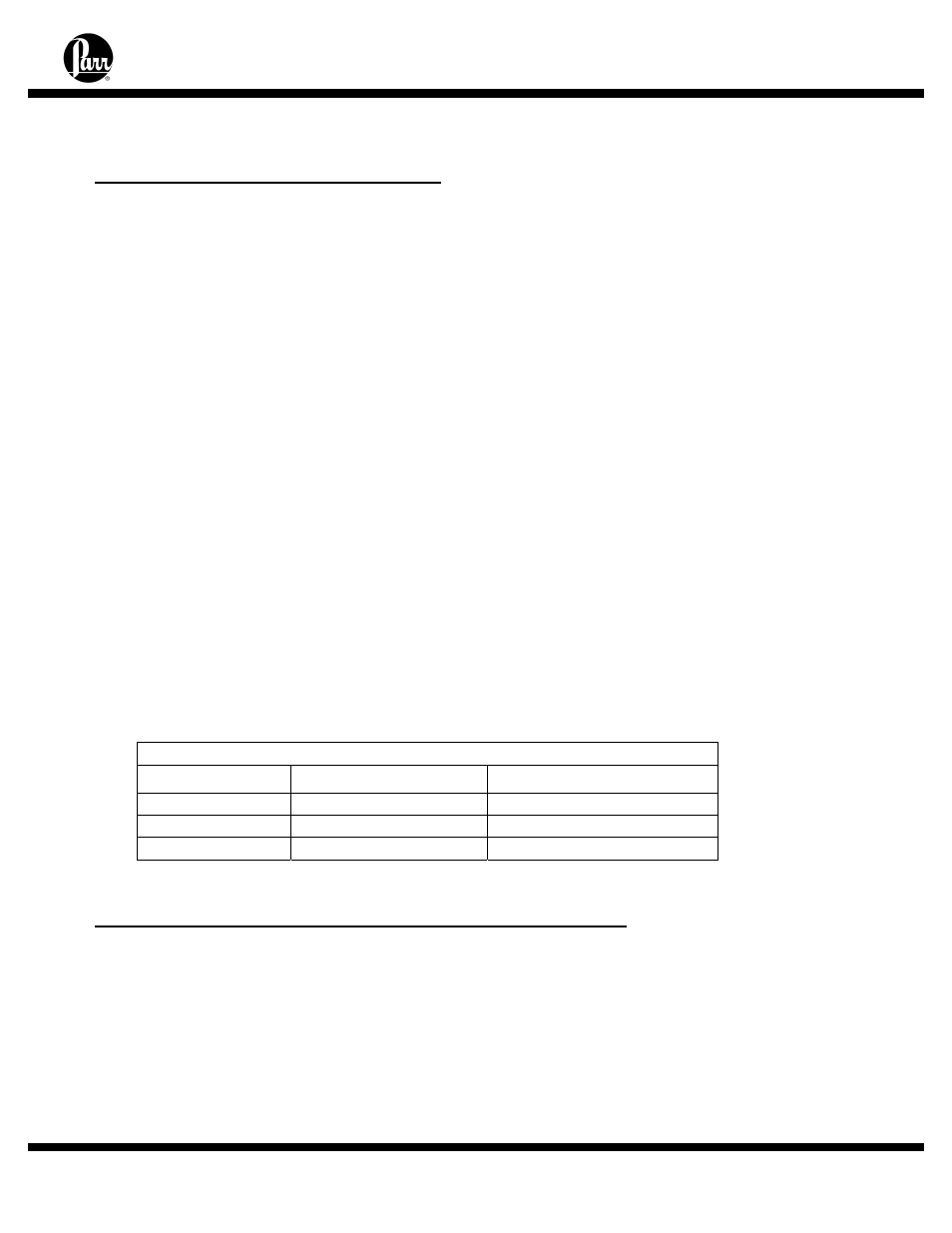

Pressure and Temperature Limits

Vessel Material Maximum Pressure Maximum

Temperature

T316SS

1900 psig

350° C PTFE Flat Gasket

T316SS

1900 psig

225° C FKM O-ring

T316SS

1900 psig

275° C FFKM O-ring

A1761HC3 400/415V 3-Phase "Y" Slave Box Control

Installation of a 3-phase slave box requires a switch or circuit breaker installed in the

building.

1. It shall be in close proximity to equipment and within easy reach of the operator.

2. It shall be marked as disconnecting device for the equipment.