Cylinder slide adjustment – Parr Instrument Series 4558 User Manual

Page 13

4555 - 58 Series

5G & 10L Pressure Reactors

- 12 -

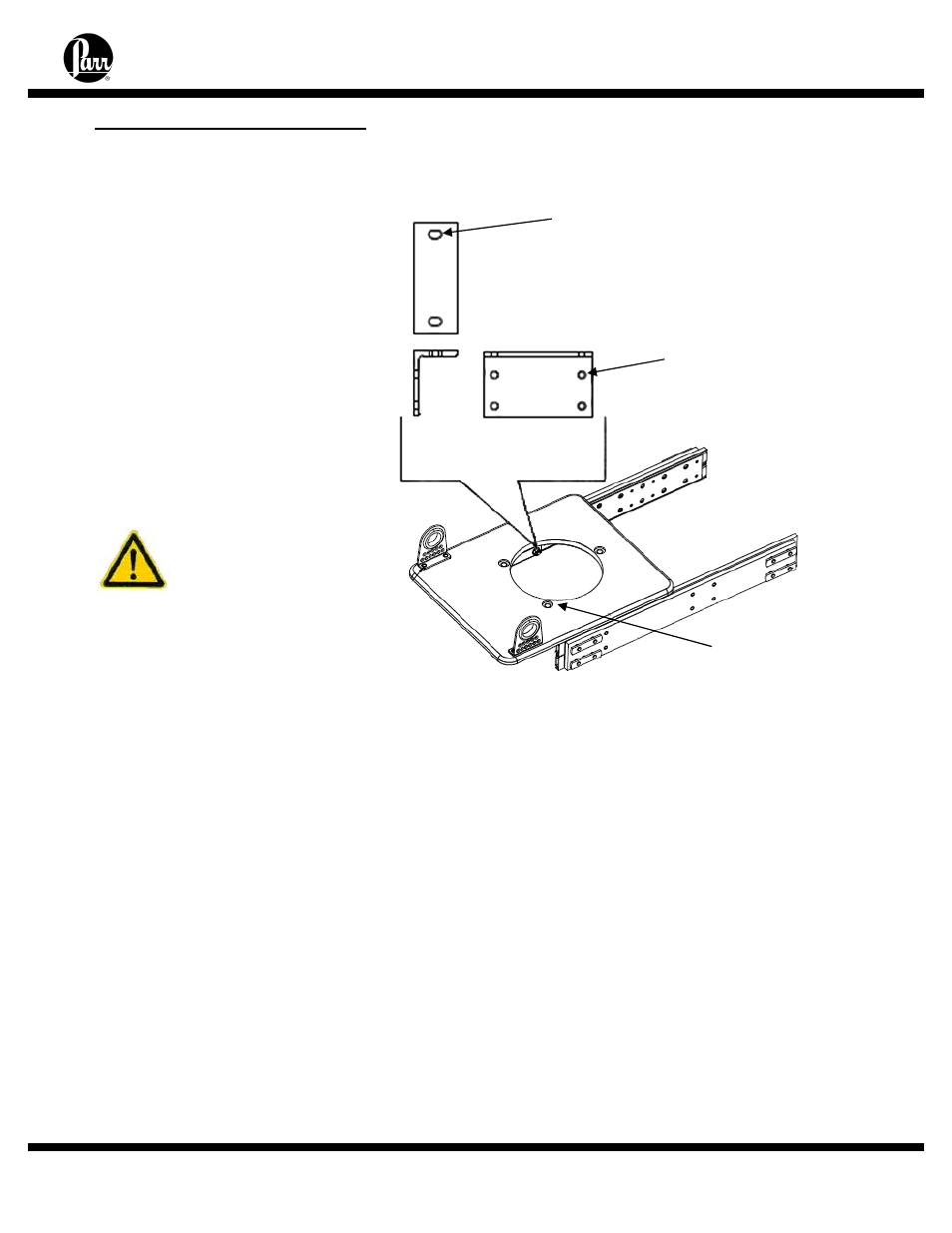

Slotted holes for

center adjustment

(Left/Right)

(4) 5/16 x 1/2”

Oversized holes for

level adjustment

(Sagging)

(4) 5/16 x 3/4” Bolts

Holes for

cylinder

mounting

(3) 3/8” Nuts and

Flat Washers

Cylinder Slide Adjustment

Minimal, if any, adjustments

are required for binding or sagging

of the cylinder slide support.

Note: To adjust for sagging, the

cylinder must be removed from the

Slide Support. This can be done

by leaving the closure intact with

the head and cylinder and

removing the (3) 3/8” nuts from the

bottom of the cylinder standoffs.

Lower the support stand

accordingly. This may require

removal of any plumbing devices

or accessories located on the

bottom of the cylinder.

Caution: The

cylinder is very

heavy and caution

should be

observed when the

cylinder is

disconnected from

the Slide Support.

1. Any adjustments to the Slide Support must be made with the Slider Support in the “IN”

position. Adjustments in the “OUT” position can cause unwanted binding to occur.

2. Once the (3) nuts have been removed from the bottom of the Slide Support, the Slide

Support can be lowered. It can then be leveled by loosening the Angle Support Brackets

detailed in the figure F1. Gently loosen the (8) horizontally mounted 5/16 x ¾” fasteners on

the Angle Support Brackets and adjust the Cylinder Support until it is level. Then tighten the

(8) 5/16 x ¾” fasteners accordingly.

3. Loosen the (4) 5/16 x ½” vertically mounted fasteners on the Angle Support brackets

until the support bracket moves freely. Center (left to right) the Slide Support and ensure

that there is no excessive force being applied against or away from the slide rails. Then

tighten the (4) fasteners accordingly.

4. Raise the Slide Support to the bottom of the cylinder until the standoffs are inserted into

the holes provided on the Slide Support. Attach the Slide Support to the cylinder using the

3/8” nuts previously removed.