Other vessel head fittings, Safety rupture disc, Type j thermocouple – Parr Instrument Series 4558 User Manual

Page 15: Pressure gage, Gage and valve adapters

4555 - 58 Series

5G & 10L Pressure Reactors

- 14 -

OTHER VESSEL HEAD FITTINGS

Safety Rupture Disc

There is a safety rupture disc attached to the head which is intended to rupture and

release the pressure before it reaches a dangerous level. A metal tag wired to the safety

head identifies the burst pressure at room temperature for that particular disc. A similar tag

is furnished with each replacement disc. This tag must remain with the apparatus at all

times so that both present and future operators will be aware of the disc rating. Users

should read the discussion of rupture discs given in the Instruction Sheet No. 231M for a

complete description of the characteristics of rupture discs and the precautions to be

observed when operating pressure equipment protected by this type of safety device.

Type J Thermocouple

A Type J thermocouple in a 1/8" dia. stainless steel sheath is furnished with the reactor.

Insert this thermocouple into the head thermowell and connect it to the thermocouple socket

on the rear panel of the temperature controller using the A470E2 extension wire furnished

with the reactor.

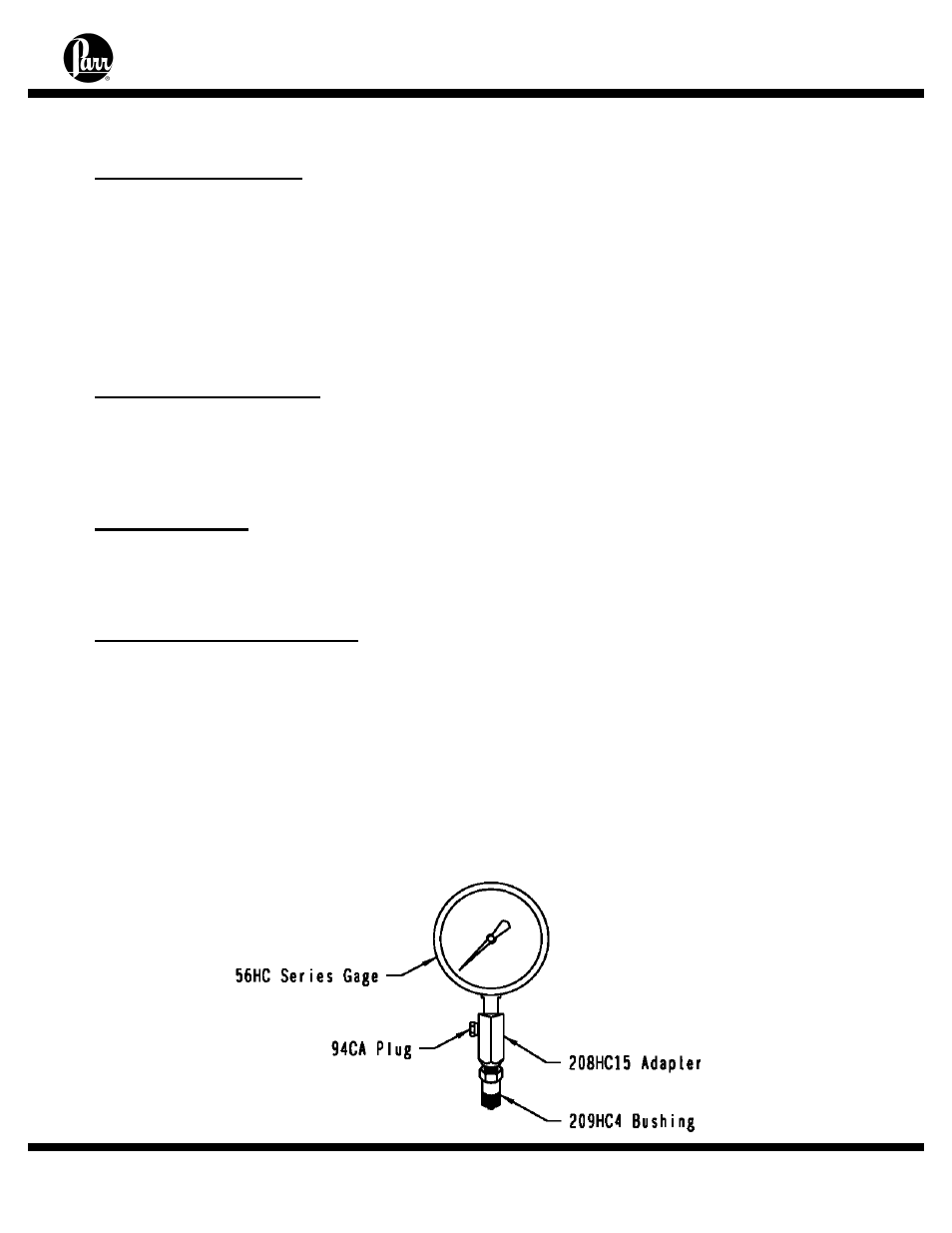

Pressure Gage

A pressure gage, typically a 0-2000 psi with a T316 Stainless Steel Bourdon tube, is

mounted on the head using attachment fittings similar to those used for the inlet/sampling

valve assembly

Gage and Valve Adapters

The pressure gage and the combined gas inlet and sampling valves are attached to the

head with an adapter which allows these fittings to be drawn up tightly when facing in any

direction. To attach these fittings to the head, screw the gage or valves firmly into the

adapter, and then run the 209HC4 bushing onto the threaded stem as far as it will go.

Screw this assembly into the head until the nose of the adapter is seated; then back it off

until the valve or gage is facing in the desired direction. Now hold the fitting firmly in place

and close the joint by tightening the 209HC4 bushing. This connection can be made and

broken repeatedly without destroying the sealing faces. A light coating of thread lubricant,

such as Parr No. 424HC2 High Temperature Anti-Seize Lube, applied to the threads and to

the nose of the adapter will help to obtain a tight joint.