Design spans between supporting purlins, Sunlite® technical guide – Palram SUNLIT User Manual

Page 13

SUNLITE® Technical Guide

11

11

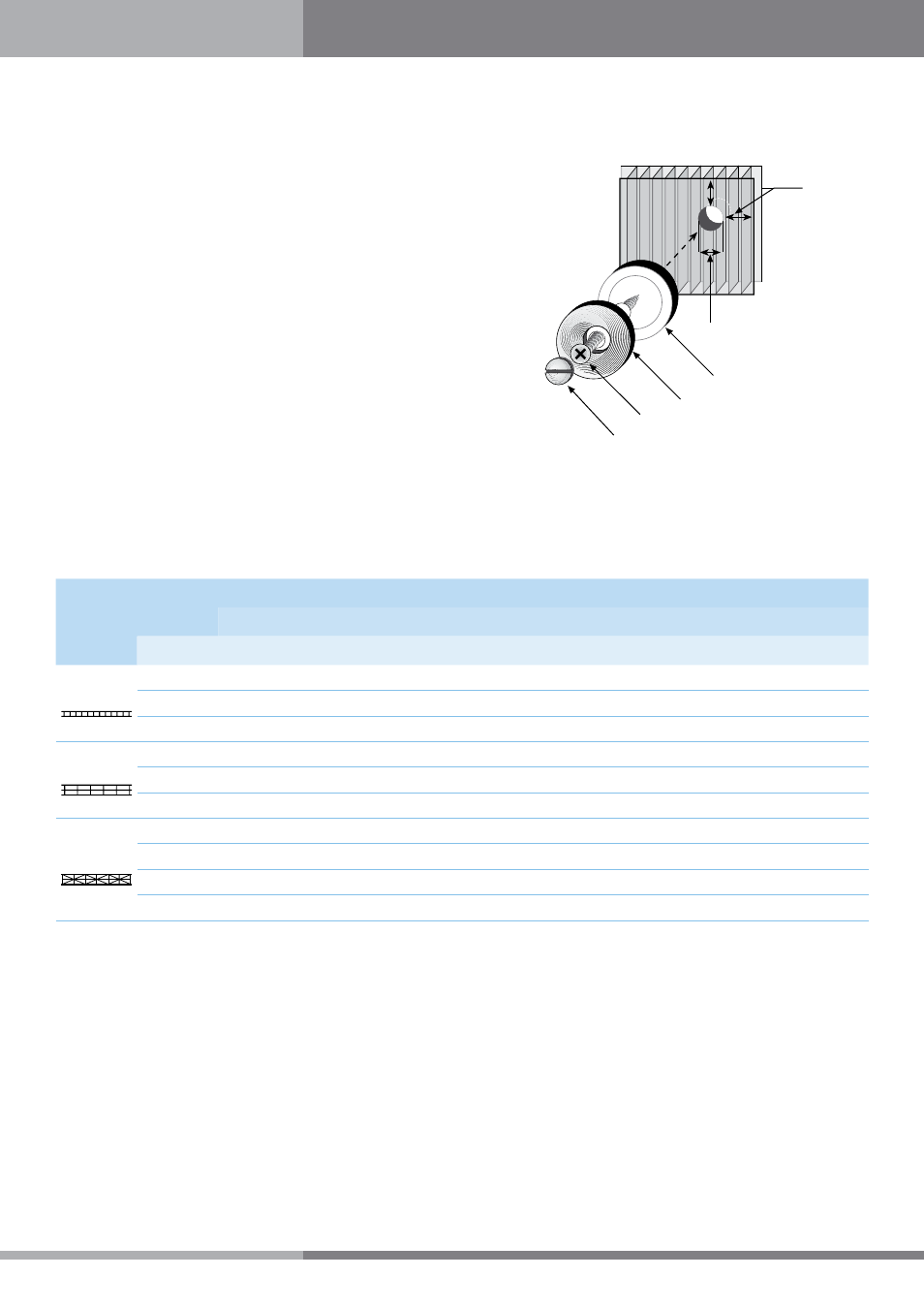

8. Screw buttons: Improved performance can be obtained by replacing the

washers with special plastic screw buttons, fitted with a suitable rubber gasket,

with or without a closing cap. They fit the thickness of each type of sheet (6, 8,

10, 16 mm, and possibly 25 mm), differing by sleeve length. Their advantage:

the sleeve prevents excessive tightening and local squashing around the

screw, and is softer on the sheet, reducing risk of tear or shear around the

screw’s stem. They also offer a seal between the fastener hole and the open

channels of the sheet, preventing possible infiltration of water and dirt into

the internal space of the sheet. Screw buttons can suit the 6.35mm (1/4 in.)

screws mentioned above, although it is recommended to use slightly longer

screws to accommodate the button thickness.

Palram recommends perforating SUNLITE for fastening as little as possible, and

prefers the use of clamped edge installation. Palram recommends that the

use of fastening screws in a glazing system, even with plastic buttons, should

be limited to economical, price conscious projects only. Two or four-sided

clamped glazing is a preferred choice.

Design spans between Supporting Purlins

According to Designated Loads for the Roofing and Cladding Method

Max. Recommended Spans between Support Purlins - Flat / Slightly Curved Roofing/Glazing

Structure

Thickness

Distance (center-to-center) between supporting purlins - according to wind/Snow loads below

50 Kg/m²

10 psf

80 Kg/m²

16 psf

100 Kg/m²

20 psf

120 Kg/m²

25 psf

mm

mm

Inch

mm

Inch

mm

Inch

mm

Inch

Twin Wall

6

900

36

800

32

650

26

500

20

8

1150

46

1000

40

850

34

650

26

10

1250

50

1150

46

1050

42

900

36

Triple Wall

8

1120

44

970

38

820

32

620

25

10

1220

48

1125

45

1020

41

870

35

16

1600

64

1450

58

1250

50

1130

45

X-Lite

16

1650

65

1500

59

1300

51

1180

46

25

1850

74

1700

68

1550

62

1425

56

32

2050

82

1900

76

1750

69

1600

63

35

2075

82

1925

76

1775

70

1625

64

Notes:

1. Span calculation is based on general professional know-how, previous experience & specialized expertise with this type of products.

2. Spans depicted are drawn from loading tests and extrapolations based on L/20 deflection (5%) at the specific span and load using continuous multi-span

supports. The values refer to mid-spans. Edge-spans (lower & upper ends) should be approx. 20% smaller.

3. SUNLITE panels can withstand higher loads and/or wider spans without failure. However the involved deflections will exceed L/10 (10%) of the span, which is

unacceptable in most cases.

Curving SUNLITE sheets gives them higher strength and rigidity, as in the case of two-sides clamping described in the next page.

>2 mm more than

diameter of button stem

Rubber gasket

Plastic button

Fastening screw

Optional cover

>30 mm

Figure 14