Lingenfelter L460285297 & L460316109 Lingenfelter LNC-TRM Torque Reduction Module v1.2 User Manual

Page 9

Page 8

Notes:

• Changes to the switch point settings (Retard Slope, Max Retard, Kill Time, Kill Time Adder)

require the unit to be powered down for the changes to become active

• The switch positions are ONLY read on start up

• The LNC-TRM timing reduction can be activated at any RPM

• At low RPM the maximum amount of timing retard the LNC-TRM is able to achieve is based on

the maximum amount of time it can delay a cylinder firing event (0.0030 seconds). This means that

below 2778 RPM the maximum amount of timing retard available is less than 50 degrees. At or

above 2778 RPM the maximum timing retard is fixed at 50 degrees. Below that RPM the maximum

amount of timing retard available is as follows:

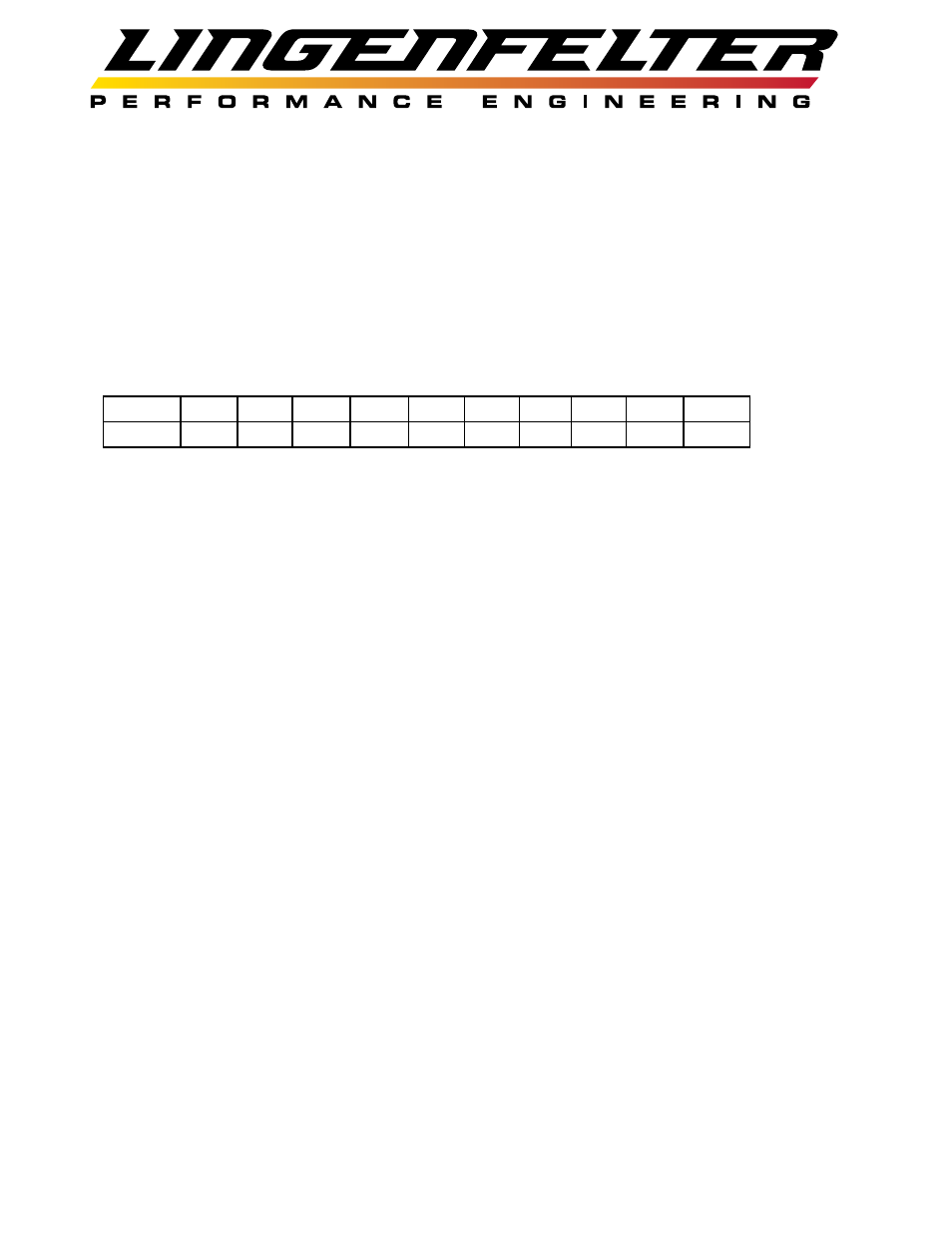

RPM

500

750

1000 1250 1500 1750 2000 2500 2778 3000+

Degrees 9

13.5 18

22.5

27

31.5 36

45

50

50

• If you have the Max Retard switch set to a timing retard value higher than what can be achieved, the

LNC-TRM will only provide amount of timing retard that is possible (as shown in the table above).

If the Max Retard switch is set to a lower timing retard value than the table value then the amount of

timing retard will not exceed that value.

• The length of time the digital activation input is connected does not impact the length of the torque

reduction event unless “Kill Time” is in position “F” (OFF).

• You must disconnect/disable the digital input to reset the torque reduction event and be able to

trigger a new torque reduction event.

• If the two digital inputs are directly connected to each other (green to yellow wire) then a single

torque reduction event will occur on initial start-up and then the two wires will need to be

disconnected from each other to reset the system and allow another torque reduction event to

occur.