Labconco FreeZone and FreeZone Plus 6, 12 and 18 Liter Freeze Dry Systems 79600 Series User Manual

Page 20

16

Chapter 3: Getting Started

Product Service: Domestic 1-800-522-7658, International 816-333- 8811

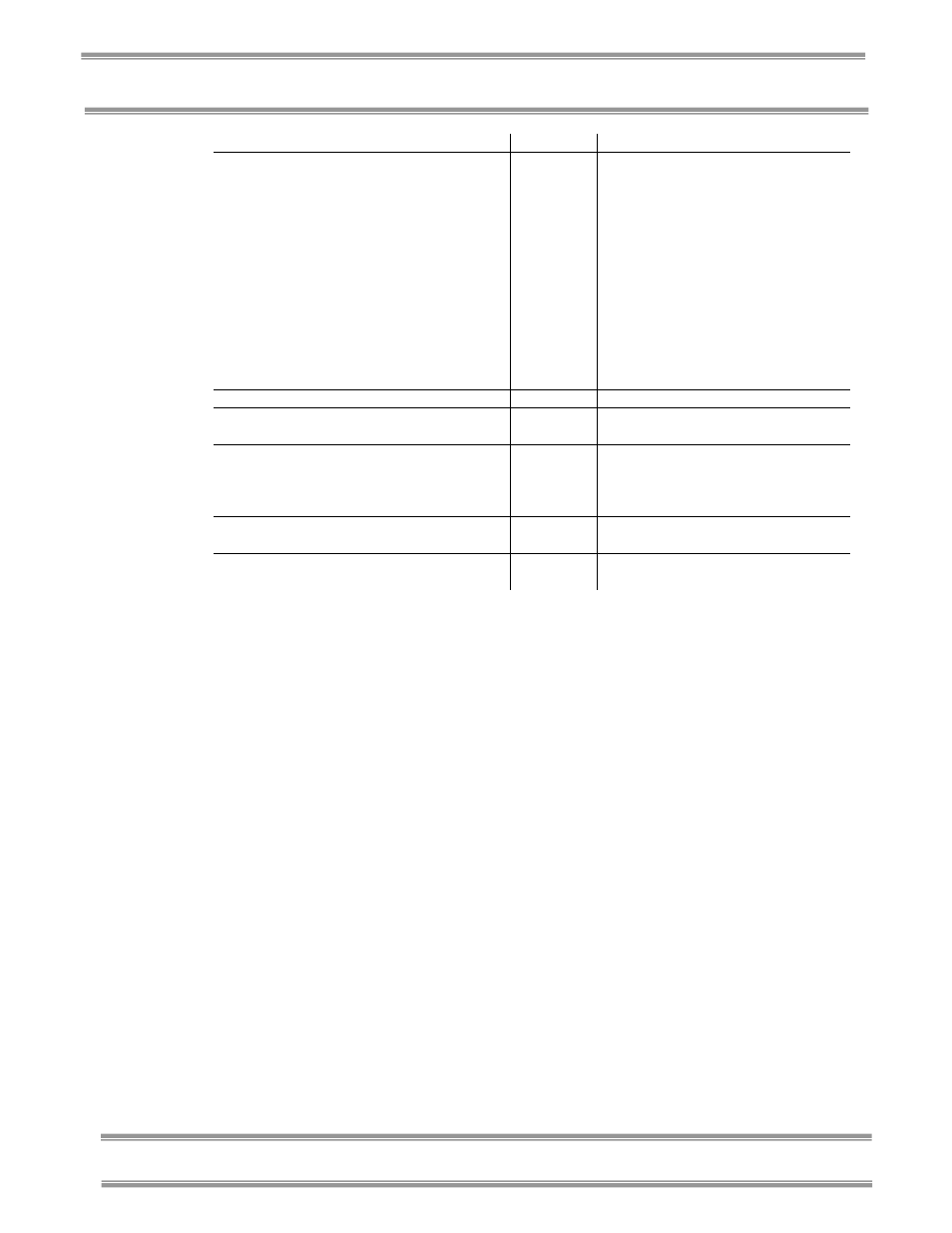

Acids

Buffers

Solvents

Component Material

Acetic Acid 20

%

Formic Acid

Trifluo

roa

cetic Acid

(TFA)

Ca

lcium Chloride

Sodium

Ph

os

phate

Acetone

Acetonittirle

C

arbon Tet

rochlo

ride

Cycl

ohe

xane

D

iox

ane

Methy

l t-Butyl

Ether (BTBE)

Pyridine

Valve

Stem Acetal

C

D

D

D

D

Collector*

Lid

Acrylic

D

D

D

D

Hoses,

Gaskets &

Valve

Bodies

Neoprene

C D D C C D D D C D

Flask Top

Silicon

Rubber

C D D D D D C D

Chamber &

Fittings

Stainless

Steel

C

* An accessory glass lid is available.

C – Moderate degradation; Limited use.

D – Severe degradation; infrequent use recommended; immediate

thorough cleaning required.

• Most common compounds used in freeze drying processes, if

allowed to enter the vacuum pump, will degrade the oil and

cause damage to the vacuum pump.

• Sugars and proteins typically will have minimal negative effect

on any of the materials of construction.

When using compounds in the Freeze Dryer that are hostile to the

materials of construction, it is imperative the equipment is

thoroughly cleaned after use.

- FreeZone and FreeZone Plus 6, 12 and 18 Liter Freeze Dry Systems 79340 Series FreeZone and FreeZone Plus 6, 12 and 18 Liter Freeze Dry Systems 77550 Series FreeZone and FreeZone Plus 6, 12 and 18 Liter Freeze Dry Systems 77540 Series FreeZone and FreeZone Plus 6, 12 and 18 Liter Freeze Dry Systems 77535 Series FreeZone and FreeZone Plus 6, 12 and 18 Liter Freeze Dry Systems 77530 Series