HITEC Optic 6 Sport 2.4 User Manual

Page 18

Page 33

Page 34

S. TRM (Sub Trim)

Set Up a Throttle Rudder Mix

P. MIX (Programmable Mix)

In this screen you can activate the ability of the Optic 6 Sport to create a custom-made,

programmable mix of any two servo channels in which one servo is electronically "slaved" to another.

This is a relatively advanced function.

The program also provides a way to change the value of the response of the slave servo to that of the

master.

For example you could slave the elevator servo to the throttle channel so that when you increase

the throttle, a slight downward movement of the elevator kicks in to automatically compensate for any

up-pitching due to the increased thrust.

Another typical mix might be to mix rudder with the throttle to reduce yawing.

The Optic Sport's mixing program also offers an advanced function (call TRM P MIX) that, when activated, allows both servos to be

trimmed by the same master servo trim button on the radio case-a useful option when, for example, you are using two servos to control a

split elevator.

When you apply throttle to a powerful motor, the resultant torque from the spinning propeller often tends to make the plane yaw to one side

(usually to the left).

This not only interferes with precision aerobatic maneuvers, but it makes it difficult to keep the model aligned with the runway during a

full-power takeoff. To reduce the "pilot load" of having to correct the yaw with your left thumb on the rudder stick, you can use the P-Mix

program function to automatically mix a proportional amount of rudder with an increase of throttle.

Now let's set it up:

P. Mix Trim:

1) Enter the Main Function menu and scroll down to the P MIX screen with the EDIT buttons.

Activate the function by pressing both DATA buttons-"Inh" will turn off and the default screen

shows "CH" with "MAS" blinking beneath. If, instead, a percentage value is blinking use the

right-hand CURSOR button to scroll over until you get this "CH" and "MAS" configuration.

One of the servo channel numbers will also be showing-the default is "1".

2) To make the throttle the master channel, push a DATA button to light up "3".

Now push the right-hand CURSOR once more: "SLV" will light up with a number.

Use a DATA button to change this number to "4". Now the rudder channel is slaved to

the throttle channel.

3) Push the CURSOR button again: MAS 3 and a percentage value will be blinking.

Use the DATA buttons to set the value of rudder travel to throttle travel-change to a negative

value to move the rudder in the opposite direction if necessary.

You won't likely need more than 15% to counteract the torque, but only flight-testing will tell for sure.

Set up a double-servo elevator with coordinated trim function

The Optic 6 Sport 2.4GHz offers an unusually sophisticated nuance with its P-MIX function: the ability to trim two servos simultaneously.

This is especially useful if you are using two elevator servos (one to each half of the elevator). In flight, if the elevator needs to be trimmed,

you can make the adjustment with the trim button next to the right-hand joystick on the case instead of having to enter the model setup

programming in order to trim the servos independently.

Lets set this example up:

1) Enter the P MIX screen and select the master and slave servos

(2 and 5 on this radio for split elevators) and then select the travel value (most likely 100% unless

your servo pushrods are not set up exactly the same way).

2) Now use the Right CURSOR button to move to the P MIX screen where "TRM" is blinking.

The default setting is "OFF"-turn it to "ON" by pressing the CLEAR button.

3) Exit the menu and you now have a split elevator with trim function.

S. TRM (Sub Trim)

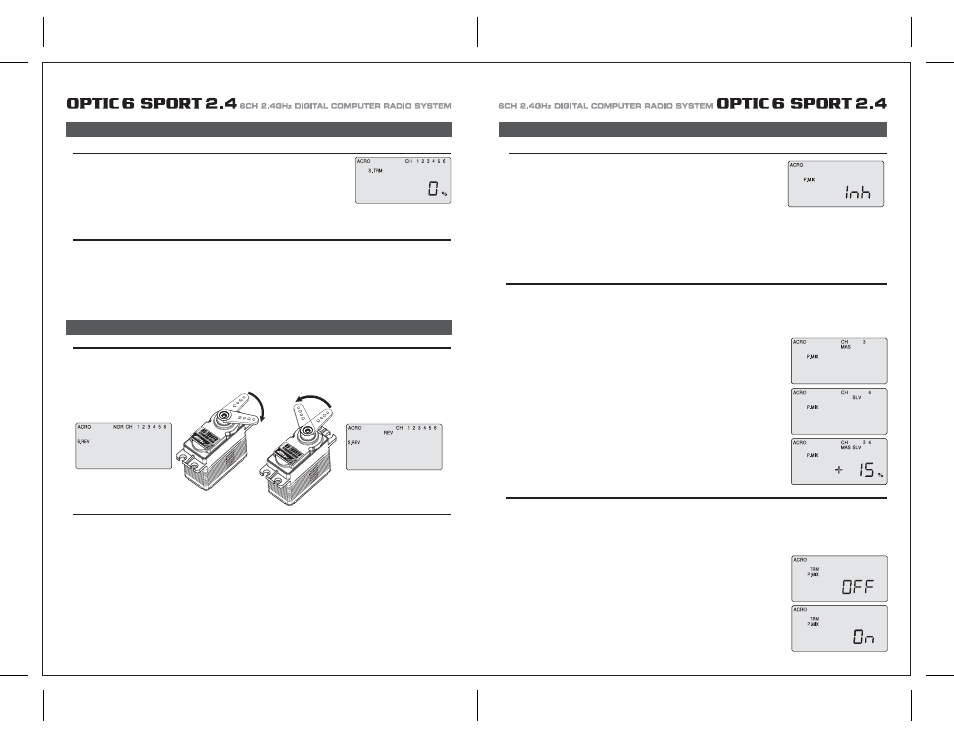

S. REV (Servo Reverse)

This is a programmable function for setting the subtrim values for each of the servos,

allowing you to make fine adjustments to each individual servo independently of the trim buttons

located on the radio case (which can be adjusted in flight).

We recommend that you first set up the model's servo pushrods so that the control surfaces are as

centered as possible mechanically (with the transmitter's case-mounted trim buttons digitally centered)

before attempting to adjust them in the subtrim menu. We also recommend that you try to keep all the

subtrim values as small as possible. If the values are large, the servo's full range of travel may be restricted.

Setting Sub Trims

S. REV (Servo Reverse)

At this point you must have your plane in front of you and turned on so you can actually see when the control services are in alignment as you

change the sub-trim value.

1. Starting with the CH 1 aileron servo, use the DATA buttons to either increase or decrease the subtrim value until the control surface is

properly aligned on the model.

2. Move over to CH 2 with the right-hand CURSOR button and align the elevator in the same way.

3. Continue by moving to CH 4 and align the rudder, to CH 6 to adjust the aileron servo in channel 6 and to CH 5 to adjust the flap.

When you first turn on your model, you will immediately see whether all the control surfaces are moving in the correct direction when you

wiggle the controls.

If any are moving in reverse, you can come to this screen to reverse the throw of the offending servo.

Reversing a Servo

P. MIX (Programmable Mix)

Let's say your elevator is going down when you pull back on the joystick-that is definitely not going to be a good situation when you go to fly

your plane! To reverse the elevator servo, come to this screen and use a CURSOR button to move over to CH 2 and push both DATA buttons

simultaneously.. You'll notice that the symbol "NOR" ahead of CH has changed to "REV"-and that the servo is now operating as it should on

your model.

If any other servos need to be reversed, CURSOR over to that channel slot and push both DATA buttons simultaneously.

Normal

Reversed