Maintenance, 14 trouble-shooting – Glow-worm Ultimate c User Manual

Page 30

0020167175_01 - 02/13 - Glow-worm

MAINTENANCE

To ensure the continued effi cient and safe operation of the

boiler it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation and usage, but in general once a year

should be enough.

It is the Law that any servicing is carried out by a competent

person approved at the time by the Health and Safety Executive.

•

Before commencing with a service or replacement of parts

isolate the boiler from the electrical supply and turn off the gas

supply at the gas isolation valve.

•

When replacing a part on this appliance, use only spare parts

that you can be assured conform to the safety and performance

specifi cation that we require. Do not use reconditioned or copy

parts that have not been clearly authorised by Glow-worm.

•

If any electrical connections have been disconnected and

after their connection, checks to the earth continuity, polarity,

short circuit and resistance to earth must be repeated using a

suitable multimeter, as described in chapter "Trouble-shooting

> Fault diagnosis > Check the electrical installation".

•

After servicing, complete the relevant Service Interval Record

section of the Benchmark Checklist located in the back pages

of this document.

14 Trouble-shooting

14.1 Fault

diagnosis

The following checks should be performed before proceeding

onto specifi c diagnostics:

•

Make sure that the electricity supply has not been interrupted

and that the appliance is connected correctly (See chapter

"Trouble-shooting > Fault diagnosis > Check the electrical

installation")

•

Check the appliance’s gas supply (See chapter "Trouble-

shooting > Fault diagnosis > Check the gas supply").

•

Ensure that the isolating valves are open.

•

Ensure that the pressure indicator displays a value of 0.8 bar

(if the pressure falls below 0.4 bar, the air vent function will

run automatically for a period of 5 minutes until you see 0.5

bar on the pressure indicator). If not, fi ll the appliance.

•

Check that all external controls are connected correctly.

•

If the symbol is displayed on the screen, display the fault

code memory (see chapter " Trouble-shooting >Fault memory").

•

Press the reset button to restart the appliance.

•

Check the functional fl ow diagram.

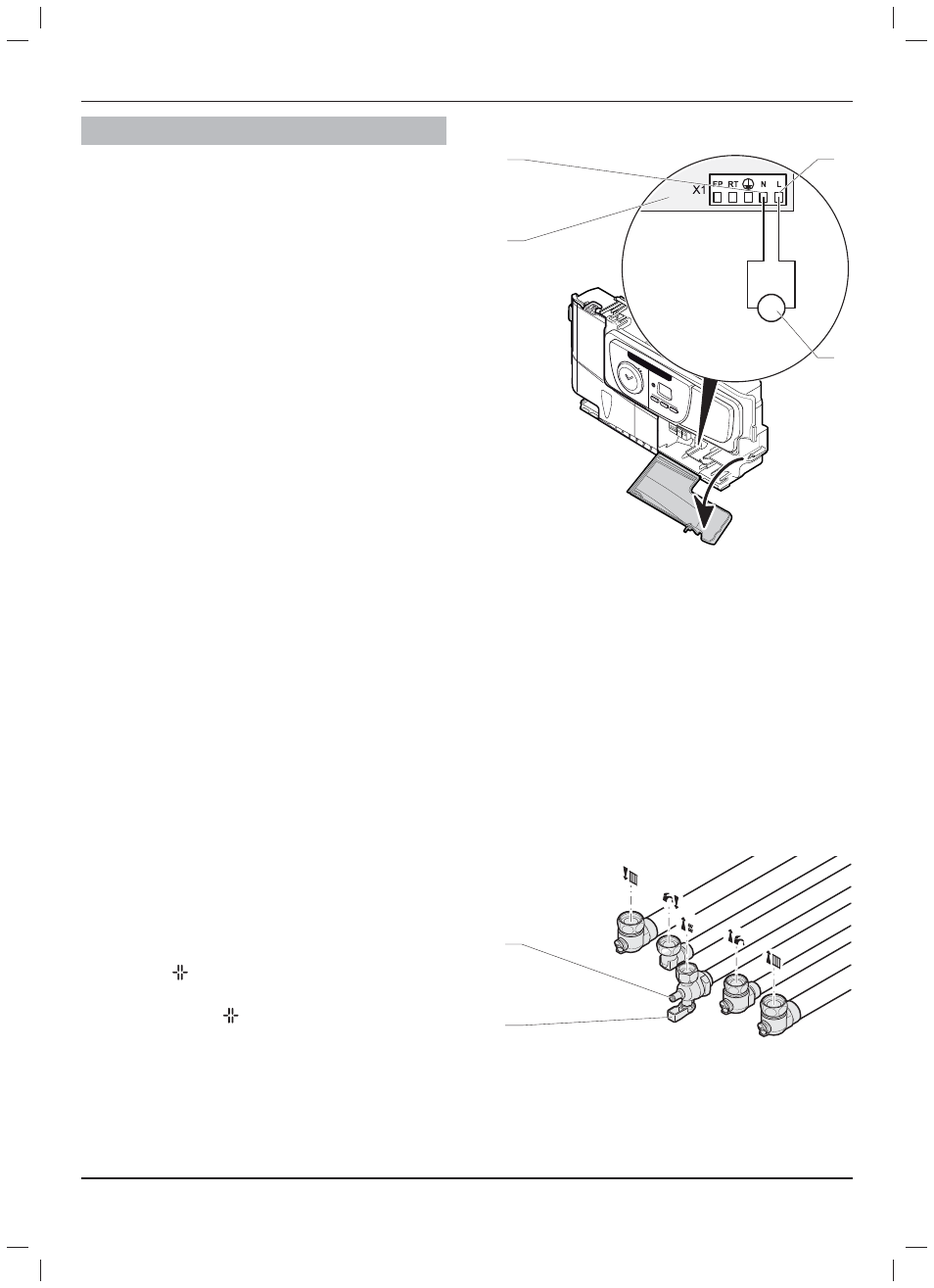

14.1.1

Check the electrical installation

24

V

V

4

3

1

2

Key

1 Main

board

2 Neutral

3 Live

4 Multimeter

•

Remove the front casing panel

•

Check the external electrical supply to the boiler is on and a

supply of 230V is present at the ‘L’ and ‘N’ terminals on the

main board.

•

Check the electrical installation and appliance, carry out tests

for earth continuity, polarity, short circuit and resistance to

earth, using a suitable multimeter.

•

Bare metal points such as screws or rivets will act as suitable

earth check points on the appliance.

14.1.2 Check

the

gas supply

1

2

Key

1 Gas service isolation valve

2 Test

point

•

Check that there is a gas supply to the boiler and the gas

service isolation valve is turned on.

•

Check pressure at the gas service isolation valve.

MAINTENANCE

- 28 -