8 servicing – Glow-worm Ultimate 80FF User Manual

Page 25

25

2000225233B

8 Servicing

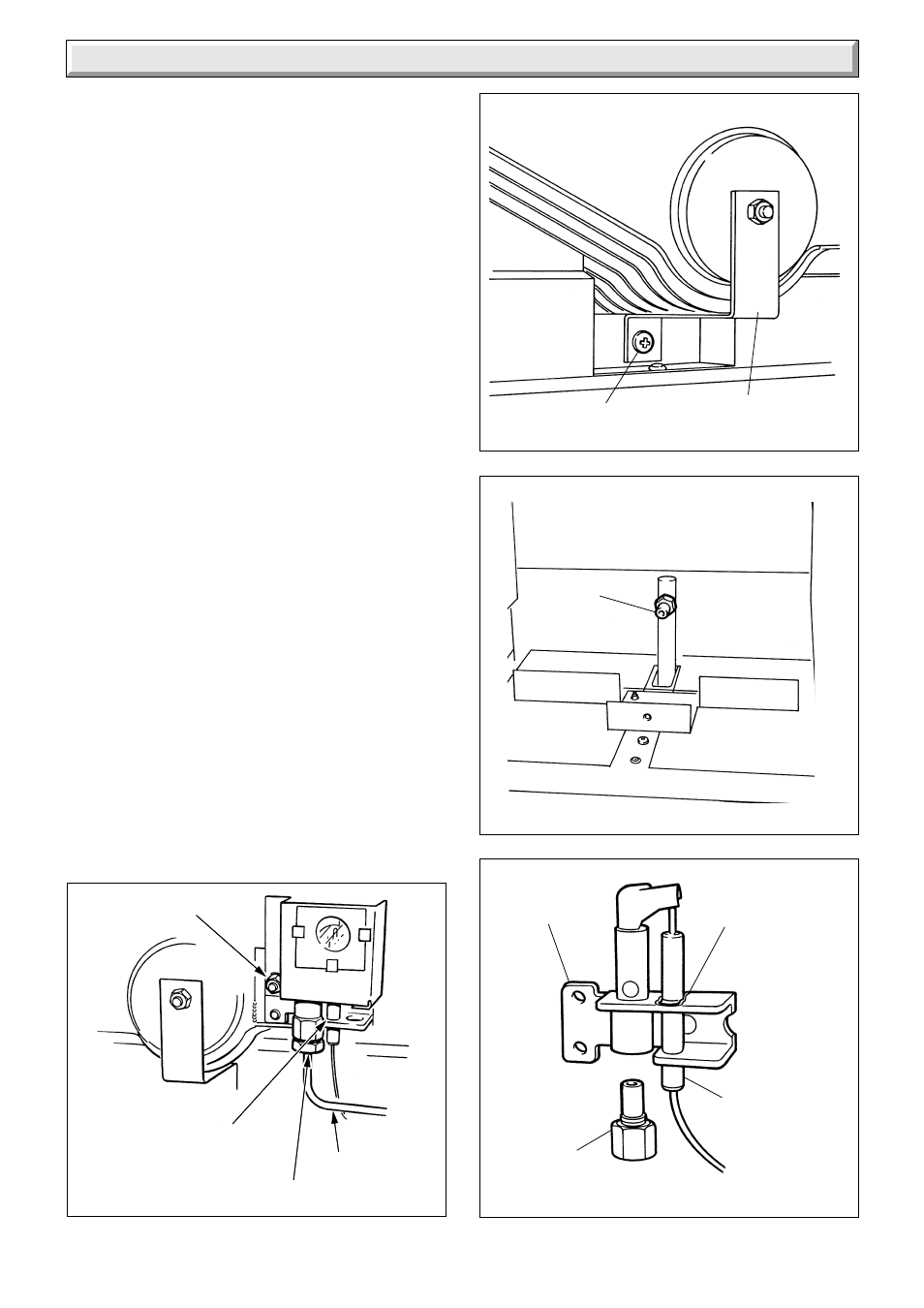

Diagram 8.4

Diagram 8.5

Diagram 8.6

SECURING

SCREW

MAIN

BURNER

INJECTOR

PILOT

BURNER

SPRING

CLIP

ELECTRODE

PILOT

INJECTOR

4112

4111

4143

Remove the main burner from the main injector at the rear.

Raise the burner up and forwards, easing the pilot pipe down,

to clear, take care not to damage the combustion chamber

insulation or the pilot p[pipe.

Use a vacuum cleaner or suitable stiff brush to clean the burner

thoroughly, making sure that all the burner ports are clear and

unobstructed.

Continue cleaning heat exchanger as Section 8.2.

NOTE: On refitting and after cleaning the heat exchanger make

sure the burner is fitted correctly, that is, located on the main

injector and horizontal.

8.4 Main Injector

With the main burner removed the main injector can be inspected

and cleaned as necessary, see diagram 8.5.

If removing for cleaning do not use a wire or sharp instrument

on the hole.

Use a little suitable sealant on the external thread when refitting

making sure a gas tight seal is made.

8.5 Pilot Burner/Electrode and Pilot Injector

Clean the pilot burner and electrode.

To remove the electrode release the spring clip, see diagram

8.6.

When removing and replacing the pilot injector from the pilot

burner take care not to damage the electrode, see diagram 8.6,

clean the injector by blowing through it.

Check that the spark gap is as shown in diagram 6.4.

8.6 Operational Checks

After completing a service and before fitting the case, check

condition of the case seal and renew if necessary.

Examine flue hood and terminal to make sure they are clean and

clear of obstructions.

Light the boiler and carryout the functional checks as described

in Section 6.

Testing Flue Gases: If any doubt exists that the flue products

are not exhausting correctly, investigate by use of a gas

analyser (FGA).

Diagram 8.3

BURNER SUPPORT

SCREW

SECURING NUT AND

SHAKEPROOF

WASHER

PILOT PIPE

ELECTRODE AND

LEAD ASSEMBLY

UNION

CONNECTOR

4109