5 boiler installation – Glow-worm Ultimate 80FF User Manual

Page 20

20

2000225233B

Diagram 5.10

4619

3310

5 Boiler Installation

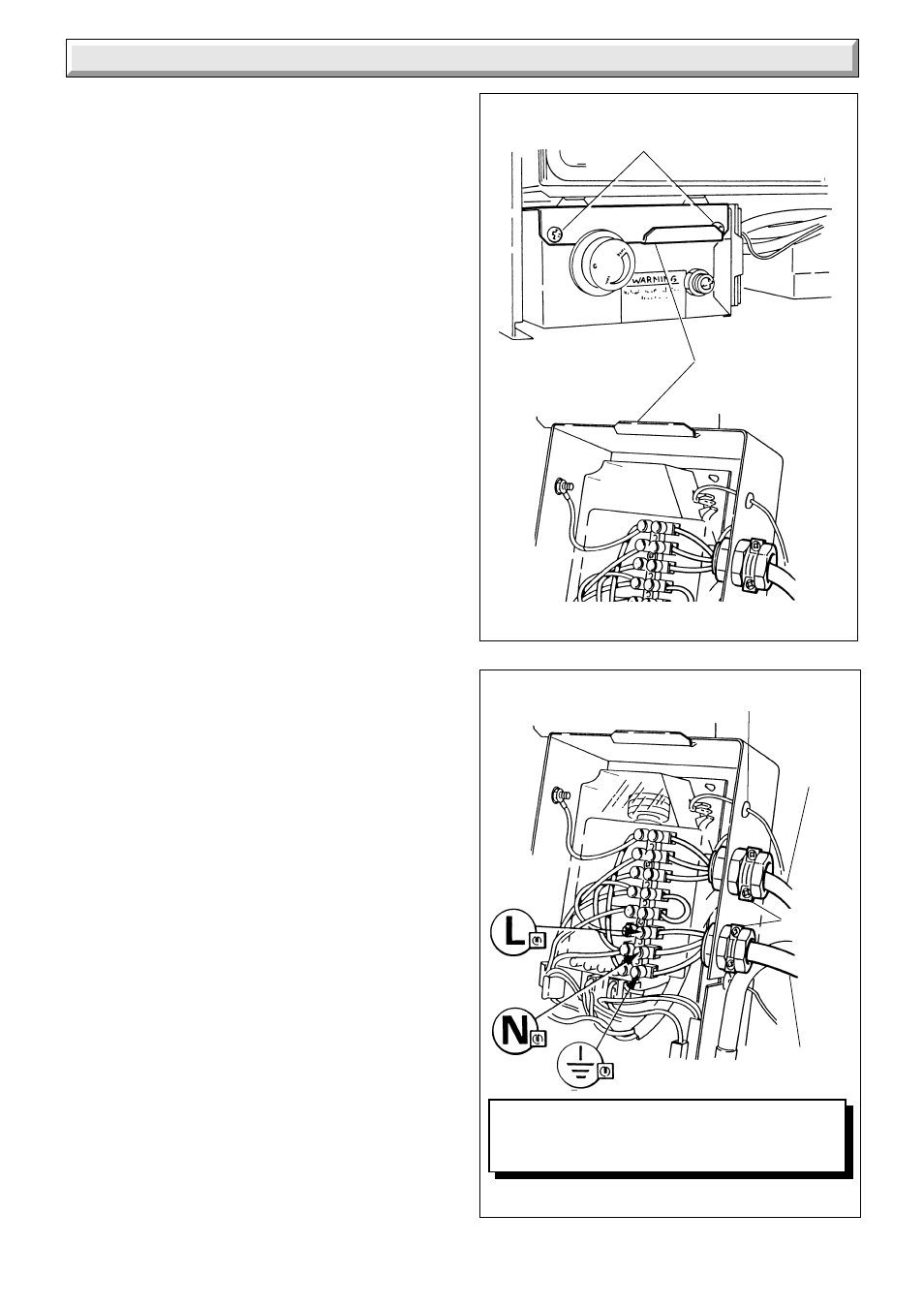

5.7 Electrical Connection

WARNING: This boiler must be earthed.

Take care not to damage any internal wiring and capillaries.

Take plastic cable retaining clip, from the loose items pack, peel

off the backing paper and position it in a suitable place to secure

the incoming cable.

Using heat resistant (to 85

o

C) cable of at least 0.75mm

2

(24/

0.2mm) to the current issue of BS6500 Table 16 and of suitable

length, thread through cable clamps, secure into the plastic

clips and connect to appropriate terminals, see diagram 5.9 and

9.5.

Standard colours are, brown - live (L), blue - neutral (N) and

green and yellow - earth (E).

The mains cable outer insulation must not be cut back external

to the cable clamp.

Make sure the cable is suitably secured.

When making connections, make sure that the earth conductor

is made of a greater length than the current carrying conductors,

so that if the cable is strained the earth conductor would be the

last to become disconnected.

5.8 Pump Connection

The pump must be connected directly to the control box, as

shown in diagram 5.9 threading the cable through the cable

clamp in the side of the control box.

5.9 External Controls

Any external controls must only be wired to interrupt the red link

between terminals SL and 9.

Make sure that the supply cable and all external cables are

secured and away from hot surfaces.

5.10 Testing

Checks to ensure electrical safety must be carried out by a

competent person.

After installation of the system, preliminary electrical system

checks as below should be carried out.

1. Test insulation resistance to earth.

2. Test continuity and short circuit of all cables,

3. Test the polarity of the mains.

The installer is requested to advise and give guidance to the

user on the controls scheme used with the boiler.

Remove red link between 9 & SL when fitting

a time control etc (if no switch is fitted, link will

make the circulation pump run constantly).

FIXING SCREWS

LIP BRACKET

IGNITION

LEAD

PUMP

CABLE

CABLE

CLAMPS

MAINS

CABLE

4620

Diagram 5.8