1 general information – Glow-worm Energy Saver 80 - 100 and Gave Valve User Manual

Page 6

6

221564F

1.1 Installation

Where no British Standards exists, materials and equipment

should be fit for their purpose and of suitable quality and

workmanship.

WARNING: When installing the appliance, care should be taken

to avoid any possibility of personal injury when handling sheet

metal parts.

The installation of this boiler must be carried out by a competent

person in accordance the rules in force in the countries of

destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

1.2 Gas Supply

This boiler is for use only on G20 gas.

The gas installation must be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion, test the gas installation for soundness using the

pressure drop method and suitable leak detection fluid, purge in

accordance with the above standard.

1.3 Data Label

The data label is on the base panel inside the appliance.

1.4 Electrical Supply

WARNING: The boiler must be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

The boiler must be connected to a permanent 230V ac, 50Hz

supply.

Connection of the whole electrical system of the boiler, including

any heating controls, to the electrical supply must be through

one common isolator.

1 General Information

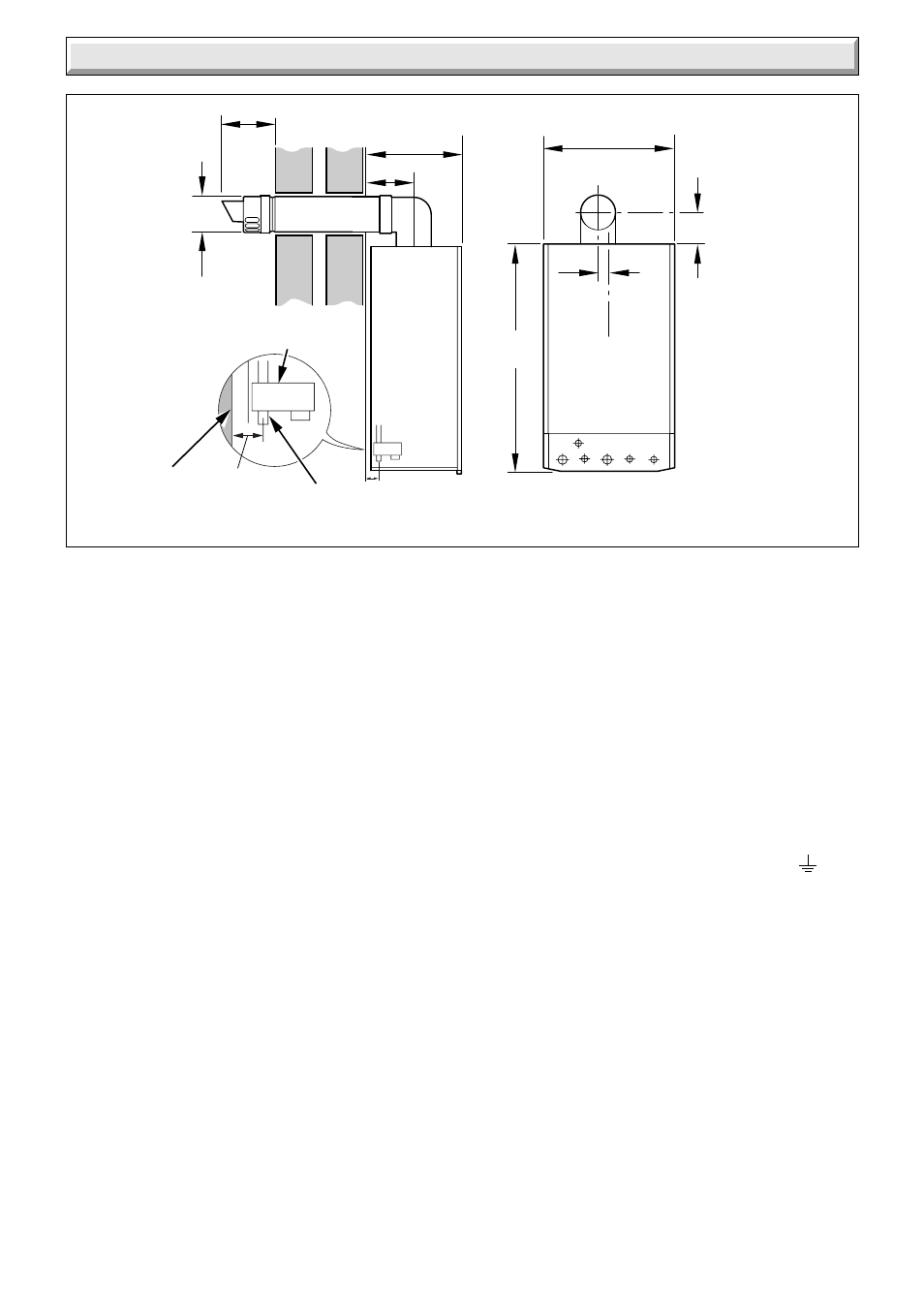

Diagram 1.1

Isolation should be by a double pole switched fused spur box,

with a minimum gap of 3mm for both poles. The fused spur box

should be readily accessible and preferably adjacent to the

appliance. It should be identified as to its use.

Alternatively connection can be made through an unswitched

shuttered socket and 3A fused 3 pin plug.

The mains supply cable and other cables connected to the

boiler must be the PVC flexible type of at least 0.75mm

2

(24/

0.20mm).

The colours of three core flexible cable are, blue - neutral,

brown - live, green and yellow - earth.

The wire coloured blue must be connected to the terminal

marked “N” or “Black”.

The wire coloured brown must be connected to the terminal

marked “L” or “Red”.

The wire coloured green and yellow must be connected to the

terminal marked “E” or “Green” or the earth symbol

.

1.5 Condensate

Being a condensing boiler, a condense drain MUST be fitted.

Condensate should, if possible, be discharged into the internal

household draining system, i.e. sink or washing machine drain.

If this is not practical, discharge can be made externally into the

household drainage system or a purpose designed soak away.

It is recommended that any external condensate drain pipe is

insulated and preferably of larger diameter to prevent it freezing

up in adverse weather conditions.

The condensate drain pipe should be checked during servicing

and any debris removed.

Refer to the British Gas Publication “Guidance Note For The

Installation of Domestic Condensing Boilers” for further

information.

CL

BOILER

CONDENSATE

DRAIN

INSIDE WALL

FIXING FACE

SPIGOT

Condensate Drain

Connection

101

145

373

208

520

118

33

145

REFER TO THE WALL TEMPLATE

FOR PIPE DIMENSIONS

145

6513

(ES80)890

(ES100)985