Important information, Introduction, Operating the boiler – Glow-worm Energy Saver 80 - 100 and Gave Valve User Manual

Page 3

3

221564F

Important Information

Protective clothing is not required when handling these articles,

but we recommend you follow the normal hygiene rules of not

smoking, eating or drinking in the work area and always wash

your hands before eating or drinking.

Insulation Pads/Ceramic Fibre, Glass yarn

These can cause irritation to skin, eyes and the respiratory tract.

If you have a history of skin complaint you may be susceptible

to irritation. High dust levels are usual only if the material is

broken.

Introduction

Gas Leak or Fault

If a gas leak or fault exists or is suspected, turn the boiler mains

electrical supply off and turn off the gas supply at the meter.

Consult your local gas company or your local installation/

servicing company.

Electrical Supply Failure

The boiler will not work without an electrical supply.

Normal operation of the boiler should resume when the electrical

supply is restored. If not, the boiler safety cut-off may have

operated, please refer to the following section to reset.

Reset any external controls, to resume normal operation of the

central heating.

The digital timer, if fitted, has a lithium battery back up and will

not need resetting.

Reset Button

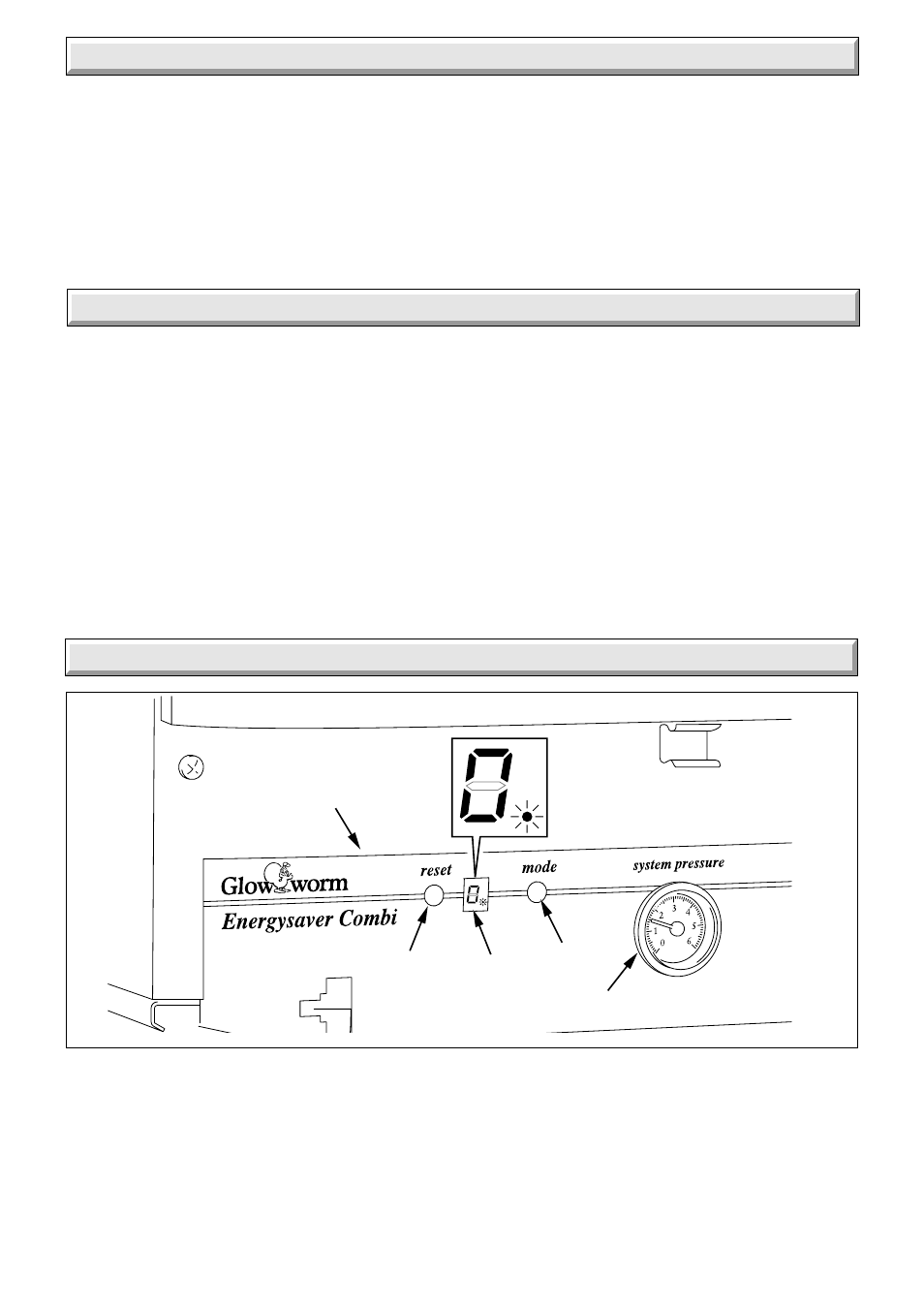

Refer to diagram 1 which shows the fascia behind the drop

down panel.

If the burner goes out check the digital display. Flashing digits

on the display indicate a fault. Allow the boiler to cool down for

at least four minutes then press the ‘Reset’ button. This should

restart the boiler.

To obtain service call your installer or Heatcall (Glow-worm’s

own service organisation) using the telephone number given on

the front page of these instructions.

6561

Diagram 1

PRESSURE

GAUGE

FASCIA

RESET

BUTTON

DIGITAL

DISPLAY

MODE

BUTTON

Operating the Boiler

To Operate the Boiler

1. Check that all five isolating valves are open with their slots

in line with the length of the valve, see diagram 8.1 in Installation

instructions.

2. CAUTION: A sealed pressurised system must be filled and

pressurised by a competent person.

Only operate the boiler when you are sure that the system has

been filled and pressurised. Check this by looking at the

pressure gauge which should read a minimum of 1.0bar, see

diagram 1.

3. Open a hot water tap, check that water flows, then close it.

4. If you are in any doubt about the boiler being filled with water

contact your installation/servicing company or the local gas

company.

5. Check that the electrical supply to the boiler is ON at the

external isolator.

Normal handling should not cause discomfort, but follow normal

good hygiene and wash your hands before eating, drinking or

going to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the skin

seek medical attention.