12 servicing – Glow-worm Energy Saver 80 - 100 and Gave Valve User Manual

Page 28

28

221564F

12.11 Heat Exchanger - Major Servicing

Refer to Fault Finding sections 13.1, (fault code

0

and

8

.) and

13.4 before carrying out a major service of the heat exchanger.

If it is suspected that the heat exchanger has become partially

blocked internally, proceed as follows.

Remove the burner and fan as described in section 12.3.

Remove the wire clip from the internal flue adaptor, see diagram

7.5.

Push the adaptor pipe downwards into the boiler flue pipe,

disengaging it from the flue elbow.

Remove the boiler flue pipe.

Check for any blockage in the boiler flue pipe and remove any

debris.

Check for any blockage in the casting flue outlet orifice and

remove any debris.

Place a suitable container below the condense drain and

remove the cap. See section 12.5.

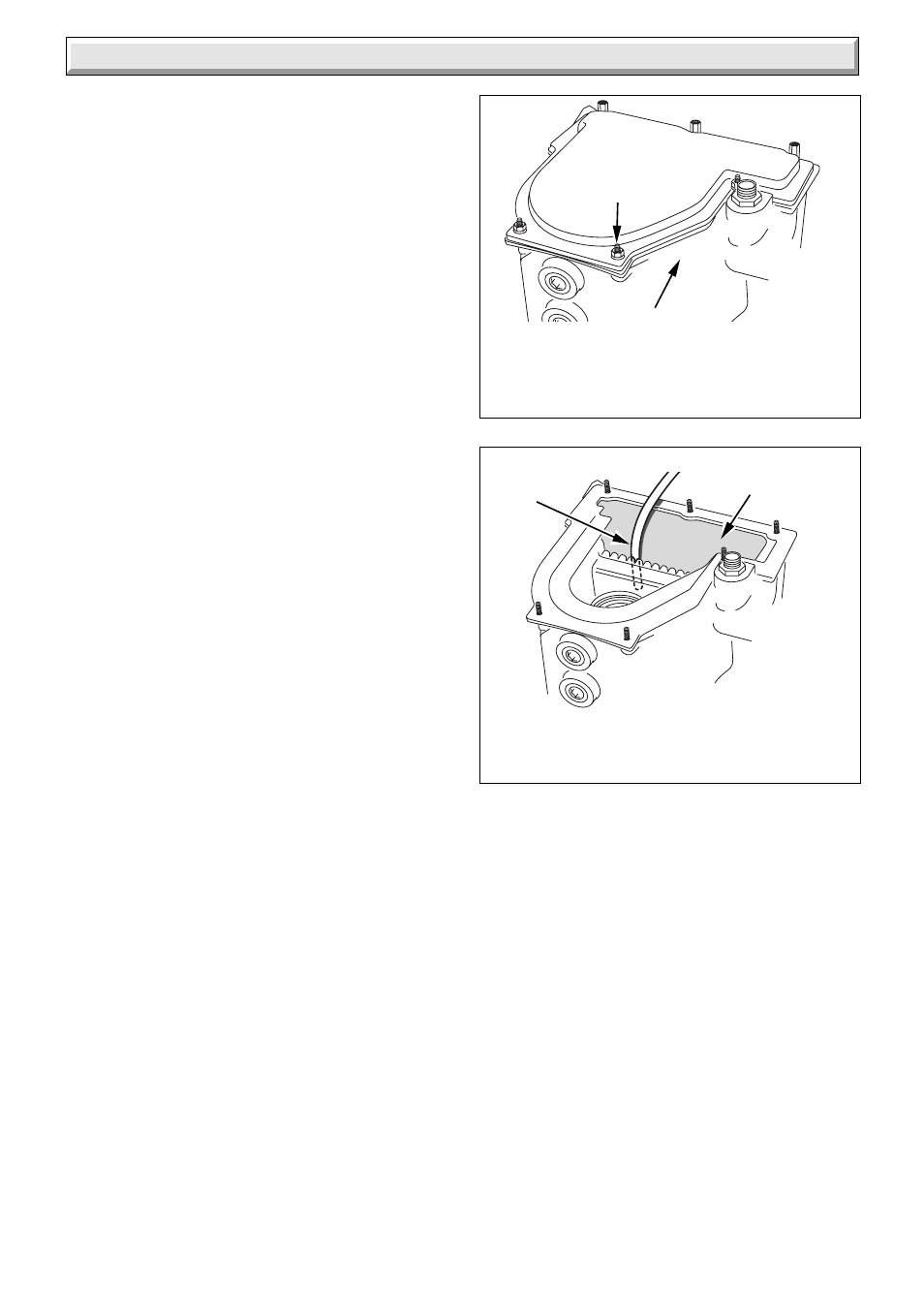

Using a suitable spanner, remove the heat exchanger top panel

nuts, see diagram 12.9. Take care when removing the nuts not

to drop them behind the heat exchanger.

Carefully prise open the boiler top, making sure that the washers

are retained on removal.

Replace the boiler flue pipe.

Place a water hose into the top of the heat exchanger, taking

care not to damage the insulation to the rear, see diagram

12.10.

Thoroughly flush the heat exchanger from above and collect the

water and any debris in the container beneath the condense

drain.

Flush the heat exchanger until the water appears clear at the

condense drain.

Check the condition of the heat exchanger top gasket and

replace if necessary.

Rebuild the boiler.

Repeat the combustion test as detailed in section 12.6.

If the combustion is still unacceptable then the heat exchanger

will need to be replaced. Refer to section 14.21 and remove the

heat exchanger.

HEAT

EXCHANGER

Diagram 12.9

6534

HOSE

Diagram 12.10

6535

TOP PANEL

NUTS (6 OFF)

Air Vent Pipe

removed for clarity

INSULATION

Air Vent Pipe

removed for clarity

12 Servicing