8 fault finding – Glow-worm Clearly Solar System Hydraulics User Manual

Page 23

23

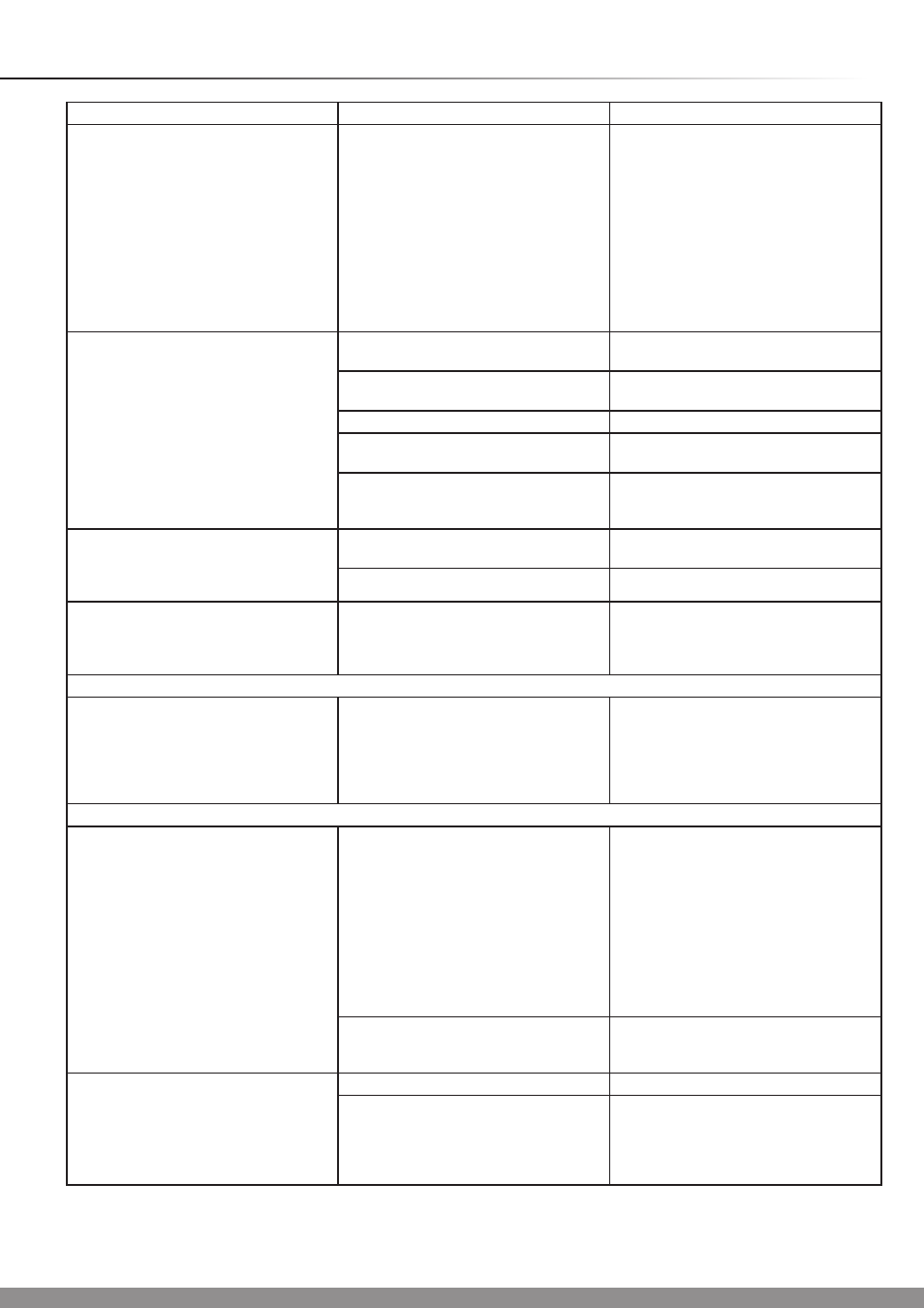

8 Fault Finding

Malfunction

Cause

Remedy

The pressure gauge indicates a drop in

pressure.

A drop in pressure is normal shortly

after filling the system, since air still

escapes from the system. If a pressure

drop occurs again later on, the cause

may be an air bubble, which has been

subsequently released.Furthermore there

are fluctuations to the pressure in normal

operation mode between 0.2 to 0.3 bar,

depending on the system temperature. If

the pressure drops continuously, there is

a leak in the solar circuit, in particular in

the collector array.

First check all screw connections, stuffing

boxes at gate valves and threaded

connections, then the soldering points.

Check the collector array and replace a

tube or the collector if necessary.

The water pressure and amount of

discharged water decreases at hot water

taps.

Pressure in the main cold water supply

too low.

Inform the user and notify the water

supply company.

Line strainer in the pressure limiting valve

dirty.

Clean the line strainer in the pressure

limiting valve and replace it if necessary.

Pressure limiting valve defective.

Replace the pressure limiting valve.

Blockage in the system.

Unblock the blockage and replace any

blocked parts.

Check the system for water leaks at the

expansion relief valve and temperature /

pressure limiting valve.

The system is making noises. Normal in

the first few days after filling the system.

If it occurs later, there are two possible

causes:

1. The system pressure is too low. The

pump is drawing air via the bleeder.

Increase the system pressure.

2. Pump power set too high.

Switch to a lower speed.

The solar gain is unusually low.

The pipe insulation is too thin or incorrect.

The system may have been designed

incorrectly.

Check the insulation. Check the layout

of the system (collector size, shading,

pipe lengths) and modify the system if

necessary.

Solar control

Display example “NTCA Err“ or similar

(reference system wiring instructions

including Fluropro solar controller)

Defective sensor (short circuit or

interruption).

1. Check the cable connection.

2. Measure the resistance values of

the disconnected sensor at known

temperatures, and compare these with

the manufacturer's specifications.

3. Inspect the piping for damage.

Solar cylinder

The cylinder cools down at night. The

flow and return temperatures vary after

switching off the pump. The collector

temperature is higher than the air

temperature at night.

1. The gravity brake is blocked.

1. Check the position of the blue handle.

2. Check the gravity brake for tightness

(jammed cuttings, particles of dirt in the

sealing face).

3. Do not connect the solar heat

exchanger directly, rather pull the supply

pipes downwards and then upwards to

the collector (syphon supports the gravity

brake) or install a 2-port valve, which

is switched on at the same time as the

pump.

2. One-pipe circulation in the event of

short pipe networks with low pressure

loss.

Install a gravity brake (as close as

possible to the cylinder).

Reheating is not working. The boiler

runs for a short time, goes off and then

back on again. This is repeated until the

cylinder is at its target temperature.

1. Air in the reheating heat exchanger.

Bleed the reheating heat exchanger.

2. Heat exchanger surface area too small. Compare the specifications of the boiler

manufacturer with those of the cylinder

manufacturer. The problem may be able

to be solved by a higher setting of the

flow temperature at the boiler.

Table 8.1 Fault Finding (continued)