3 component specifications – Glow-worm Clearly Solar System Hydraulics User Manual

Page 10

10

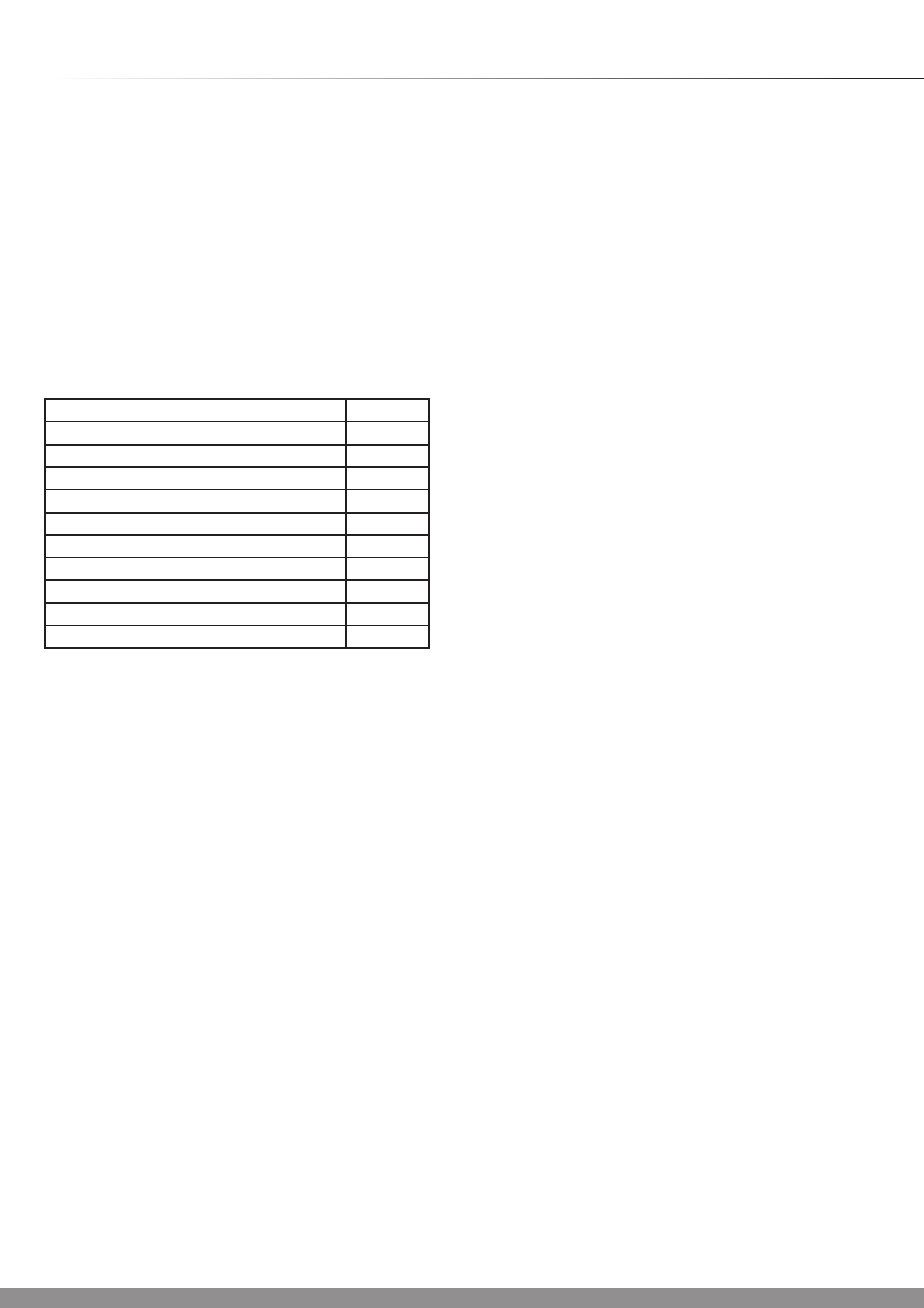

Component

Volume (l)

Flurocyl 200 l heat exchanger solar circuit

3.04

Flurocyl 250 l heat exchanger solar circuit

3.04

Flurocyl 300 l heat exchanger solar circuit

4.14

Flurocyl 200 l heat exchanger reheating circuit 3.7

Flurocyl 250 l heat exchanger reheating circuit 3.7

Flurocyl 300 l heat exchanger reheating circuit 3.7

Solar pump unit

0.9

Vertical solar thermal flat plate collector

1.85

Horizontal solar thermal flat plate collector

2.16

Protection vessel

5.0

Table 3.2 Volume of individual circuits

3 Component Specifications

3.2 Solar expansion vessel

The solar expansion vessel, is used to equalise the pressure

while the pressure relief valve blows off the solar fluid into

the collecting container via the pressure release pipe if the

operating pressure of 6 bar is exceeded.

The size of the solar expansion vessel is based on the

expansion volume of the solar system.

The expansion vessel not only accommodates the expansion

volume of the solar fluid, but also the entire volume

of the

collectors in the event of a shutdown. The total volume of

the solar system is the total of the individual values of the

collector, heat exchanger volume and the volume of the

pipeline.

The admission pressure of the solar expansion vessel can be

set between 0.5 and 4.0 bar.

3.3 Thermal cut out of the solar pump

The solar pump must be protected by its own thermal cut out

(TCO) which must be mounted on the solar cylinder (pre-

assembled at the factory on the Glow-worm Flurocyl cylinder).

The power supply to the pump MUST be interrupted at

cylinder temperatures higher than 90°C.

3.4 Solar fluid

This information applies to Glow-worm solar fluid (20 l

canister: item no. 0020054968).

Glow-worm solar fluid is a ready-mixed antifreeze and

anticorrosive, consisting of approximately 45% propylene

glycol with anti-corrosion inhibitors and 55% water. It is

resistant to high temperatures.

Furthermore the solar fluid has a high thermal capacity.

The inhibitors provide reliable corrosion prevention when

using different types of metal (mixed installations).

NOTE: Do not use any other anti-freeze or inhibitors with the

collector. Only Glow-worm solar fluid is approved.

IMPORTANT: Risk of damage! Glow-worm solar fluid is ready

mixed. You may not under any circumstances mix it with water

or other fluids. Otherwise it will become ineffective as an

antifreeze or anticorrosive, resulting in damage to collectors or

other parts of the system.

Glow-worm solar fluid is infinitely durable in hermetically

sealed containers.

Skin contact is normally not dangerous. Eye contact only

causes minor irritations, you should nevertheless immediately

wash your eyes.

Observe the safety data sheet, see section 9.

3.5 Protection of the solar circuit against frost

and corrosion

To protect the solar system reliably against frost in winter, the

entire solar circuit must be filled 100% with solar fluid.

NOTE: You can achieve frost resistance of about -28°C by

filling the solar system with Glow-worm solar fluid. No damage

is caused by frost even at outside temperatures below -28°C,

since the expansive effect of the water is reduced. Check the

antifreeze effect after filling the system and then once a year.

To check the solar fluid; refer to the operating manual of the

solar fluid tester (item no. 0020054984).