5 commissioning, 1 flushing and filling the solar circuit, 2 setting the flow rate / pump speed – Glow-worm Clearly Solar System Hydraulics User Manual

Page 16

16

5 Commissioning

You must adhere to the following procedure for the

commissioning of the total system:

Use only Glow-worm solar fluid (item no. 0020054968) for

pressure tests and for flushing and filling the solar circuit.

5.1 Flushing and filling the solar circuit

Glow-worm recommends using the Glow-worm filling pump,

part no. 0020054986, to flush and fill the solar circuit. Observe

the separate user manual when using the Glow-worm filling

pump.

Expansion vessel admission pressure

During the commissioning, the gas side admission pressure

p

v

of the expansion vessel must be adjusted to the equipment

height whilst disconnected. The static pressure p

stat

corresponds, to a certain extent, to the static height h between

the collector array and the expansion vessel.

10m static height correspond to approx. 1 bar.

p

v

= p

stat

= h x 0.1 but not less than 1.5 bar.

NOTE: A deviation from the optimum admission or filling

pressure always results in a reduction of the expansion

vessel's effective volume. This can cause operational

malfunctions.

Flushing is performed from the solar pump station to the

cylinder via the collector.

A self-priming pump with a pressure of 2 to 3 bar is required

to fill the solar circuit.

Collector circuit filling pressure

The filling pressure Pa should be approx. 0.5 bar over the

static pressure Pstat.

Pa = h x 0.1 + 0.5 bar but not less than 2 bar.

5.2 Setting the flow rate / pump speed

The 3-speed circulating pump can be fine-tuned to adjust the

flow rate to the collector's performance.

NOTE: We recommend a value of 0.66 l/min per m2 collector

surface area.

This is how to do it:

Use Table 5.1 to calculate the flow rate to be set by

multiplying the installed collector surface area with the value

of 0.66 l/m2 • min.

Set the pump speed to roughly set the flow rate as follows:-

Let the pump run first at the lowest speed (minimum power

consumption).

Check whether the calculated value is achieved on the flow

rate meter.

0,

5

1

2

3

0,5

1

2

3

4

5

6

4

5

6

L/mi

n

L/mi

n

1,1 l/min

Adjustment

Valve

Flow Rate

Display

14168

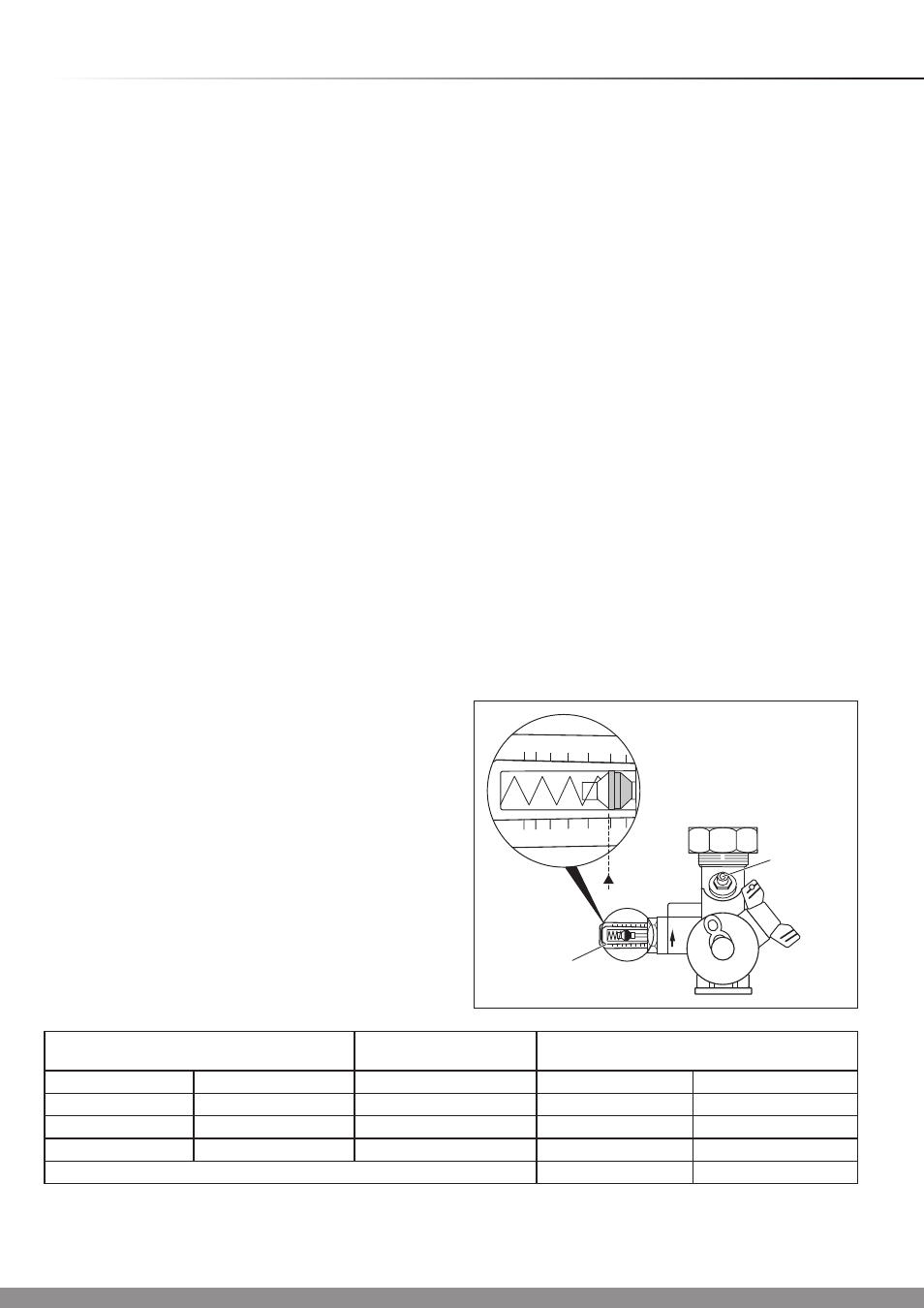

Diagram 5.1

EXAMPLE: The installed (net) collector surface area for

Clearly Solar collectors is 2.35 m

2

. Multiplied with the value

for the specific flow rate of 0.66 l/m

2

• min, it results in a

calculated flow rate, which should be indicated by the flow

rate meter, see diagram 5.1.

Select the next pump speed if the calculated flow rate is not

achieved on the flow rate meter. Switch to a lower speed if it

is exceeded. If the flow rate cannot be achieved even at the

highest pump speed, check whether it is possible to use fewer

collectors in series reverting to a combination of series and

parallel connections (eg 2 collectors in series in parallel with

an additional 2 collectors in series).

Use an Allen key to finely adjust the flow rate at the

adjustment valve, see diagram 5.1.

The adjusted flow rate can be viewed on the display, see

diagram 5.1.

Table 5.1 provides reference values for possible pump speeds

depending on the collector connection and pipe length and

cross-section.

The flow rate can be used to calculate and display the

gain. To make an accurate calculation, the flow rate must

be entered into the Fluropro solar control. You can find

further information in the separate system wiring instructions

including the Fluropro solar control.

The pump speed is used to achieve a particular flow rate

in the collector array. The final flow rate should not be

significantly above or below the calculated value. Up to 10%

lower solar gain or unnecessarily high power consumption of

the pump could occur.

Clearly Solar, solar collector panel

Flow rate

Minimum cross-section of the copper pipe in the

solar circuit at a total pipe length of:

Number

in series

l/min

20m

50m

1

1

1.55

15

15

2

2

3.1

15

15

3

3

4.65

15

15

Pump speed:

Minimum (speed 1)

Maximum (speed 3)

Table 5.1 Layout of pipe cross-section and pump speed depending on the collector connection