8 fault finding – Glow-worm Clearly Solar System Hydraulics User Manual

Page 22

22

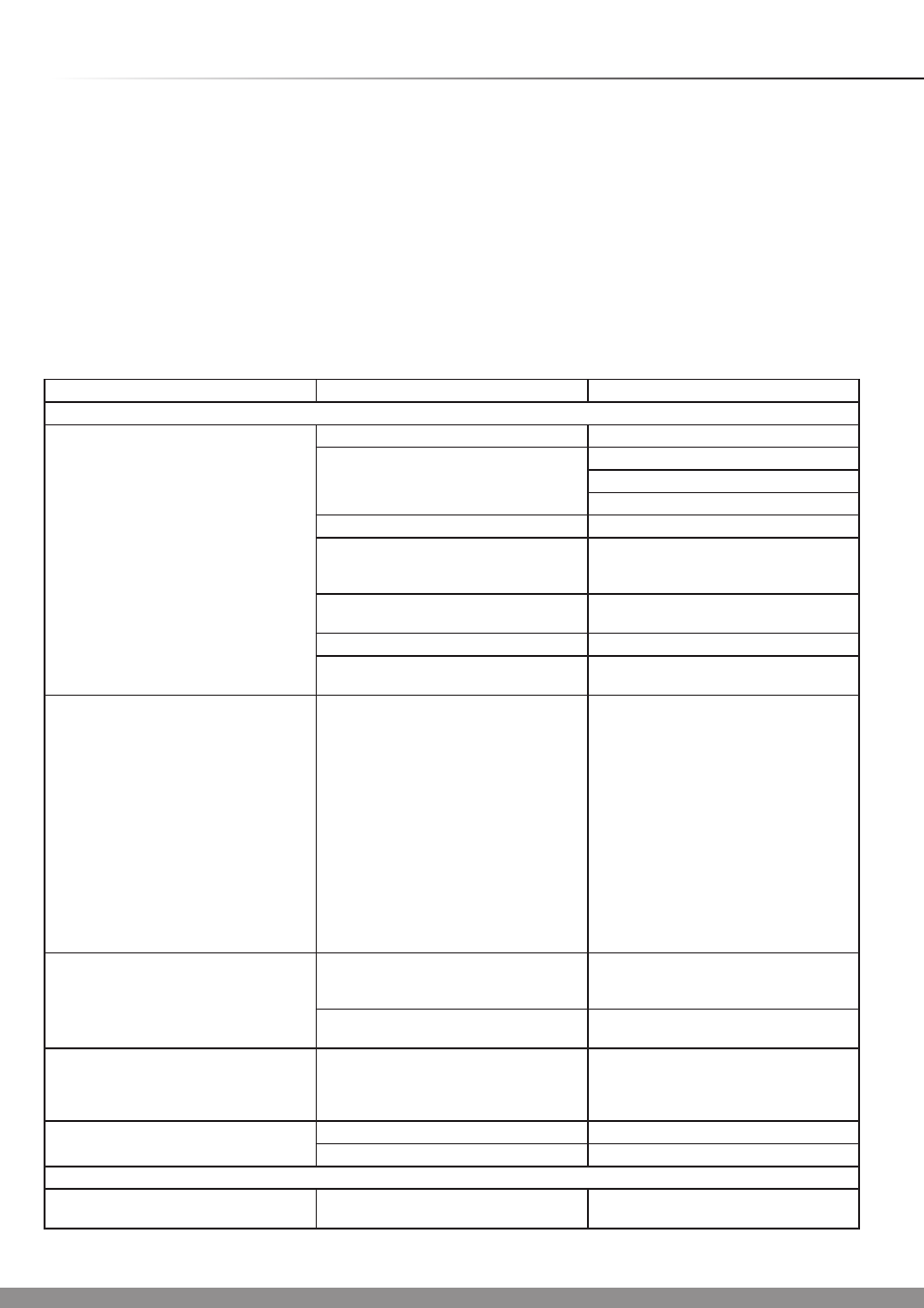

8 Fault Finding

The following tables provide information on possible

malfunctions during the operation of the solar system as well

as their cause and remedy.

All work on the Glow-worm solar system (installation,

maintenance, repairs etc.) may be performed only by

approved specialists.

IMPORTANT: Risk of serious injury or death! Never try to

correct faults in the solar system yourself. Bear in mind

that you risk death or serious injury if the work is performed

incorrectly. Consult an approved qualified servicing company

in the event of malfunctions.

NOTE: Only use original spare parts from Glow-worm. for the

replacement of parts. We recommend making a maintenance

agreement.

Malfunction

Cause

Remedy

Solar pump

Pump is not running although the

collector is warmer than the cylinder

(neither motor noises can be heard nor

vibrations felt).

1. No current available.

Check the power cables and fuses.

2.Temperature difference set too high or

controller is not switching.

Check the controller.

Check the temperature sensor.

Reduce the temperature difference.

3. Maximum temperature reached.

4. Pump shaft jammed by deposits in the

bearings.

Switch temporarily to max. speed or

unblock the rotor, insert a screwdriver in

the notch and turn it by hand.

5. Pump dirty.

Dismantle the pump and clean it. Close

the flow rate meter and pump ball valve.

6. Pump defective.

Replace the pump.

7. Flow rate set incorrectly

Check the setting and adjust it if

necessary.

Pump is running, but no solar fluid

is coming from the collector (pump

gets hot). Forward and return flow

temperatures are the same or the storage

tank temperature not increasing at all or

only slowly.

Air is in the pipework.

Check the system pressure. Operate the

pump intermittently at maximum power.

Open the bleeder at the pump and at the

cylinder and bleed. Bleed the back flow

prohibition. If there is no improvement,

check whether there is a “u pocket”

anywhere in the piping (e. g. at beam

projections or at the bend of water pipes).

Change the pipework or install additional

air vents. If the system has already been

started up and is refilled again, check

the automatic air vent: Unscrew the

protective cap and check the floater for

mobility with a blunt needle. If the floater

is jammed, replace the air vent.

Pump goes on too late and stops running

early.

1. The temperature difference between

the collector and cylinder has been set

too high.

Reduce the temperature difference.

2. Collector connection pieces not

insulated (tube collector).

Insulate the collector connection pieces.

Pump starts up and goes off shortly

afterwards. This is repeated several times

until the system runs its course. The

same occurs in the evening.

The temperature difference of the

controller is too low or the pump speed is

set too high. The solar radiation is not yet

sufficient to heat up the entire pipework.

Check whether the entire pipework is

fully insulated. Increase the temperature

difference of the controller.

The pump is making noises.

1. Air in the pump

Bleed the pump.

2. Insufficient system pressure.

Increase the system pressure.

Solar system

Clocking of the system.

Incorrect position of the collector sensor.

Position the collector sensor in the flow.

Insulate the collector sensor.

Table 8.1 Fault Finding