Introduction – Glow-worm Clearly Hybrid - Universal Module System User Manual

Page 15

0020096317_01 - 02/11 - Glow-worm

- 13 -

Key

1 Heat pump controlled by On/Off contact

2 Heat pump circuit fi lter (not supplied)

3 Hydraulic

module

4 Heat pump electrical supply + protection (This must have it's own

single isolation)

5 Heat pump control unit

6 Wireless outside sensor with solar panel

7 Systempro control unit

8 All brands of boiler controlled by 230V ON/OFF contact

9 Climapro2 RF programmable wireless room thermostat

10 Heating

circuit

11 Non-return valve (recommended to prevent burner ignition triggered

by thermo-siphoning)

12 Overheating safety (UFH shown, but can be underfl oor or radiators)

13 Glycol PRV discharge

A Heating circuit return

B Heating

circuit

fl ow

C Boiler circuit return

D Boiler

circuit

fl ow

E

Heat pump circuit fl ow

F

Heat pump circuit return

G Heat pump circuit safety valve discharge

Application conditions

- The Systempro control unit manages the operation of the

boiler, the heat pump and the module.

- The Systempro control unit manages up to 3 heating zones.

- The heat pump control unit is used as a setting tool.

- Each wireless room thermostat can control a heating zone.

- The boiler must have a 230V thermostat input.

- The installation can be performed with a low-temperature

underfl oor heating (heating outlet temperature < 50°C) or low

temperature radiators (heating outlet temperature < 70°C).

e

Use 0.75 mm² section cables for the electrical

connections to the control unit.

Control unit settings

Description of main settings

Setting

Diagram no.

6

Did you install a multizone kit ?

No

Heating curves

0.1 - 1.5

Max. heating fl ow temperature

30°C < T < 70°C

Energy effi ciency ratio

To be defi ned

Heat pump control unit settings

•

Refer to the heat pump installation notice to access the “after-

sales” parameters listed below.

Menu Function name

Setting

112

Heating curves (*)

7 - 12

114

ECO heating mode (*)

1 - 20°C

(*) Refer to the correspondence table in the “Settings > Heating” section.

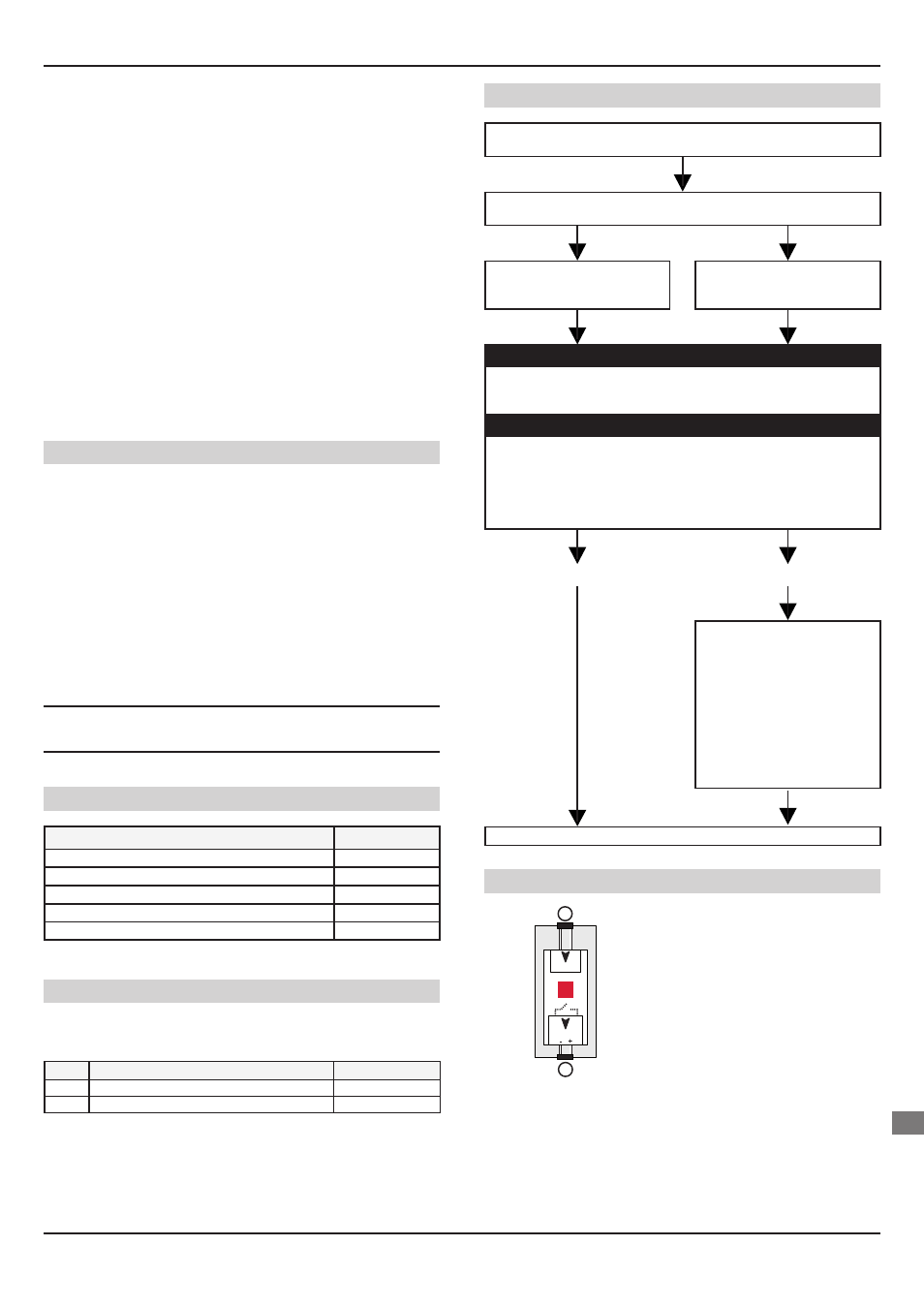

Connecting the boiler

If a room thermostat is already connected to an existing boiler, remove

it.

Check whether the room thermostat is connected to a boiler 24V or

230V input.

24V = Install a

230V/24V converter

(see below).

230V = Connect the boiler 230V

thermostat input to the "REL1"

connector of the control unit.

In the case of an existing boiler without external sensor:

Increase the boiler heating outlet temperature by 5°C.

Ensure that the heating outlet temperature does not exceed 70°C (50°C

in the case of a underfl oor heating).

In the case of an existing boiler with external sensor:

Keep the existing boiler heating curve if the comfort of the existing

installation is satisfactory.

Ensure that the heating outlet temperature does not exceed 70°C (50°C

in the case of a underfl oor heating).

Important: the setting of the control unit heating curve must be identical

to that of the boiler.

OK

NOK

Ensure that the heating outlet

temperature does not exceed

70°C (50°C in the case of a

underfl oor heating).

> If the adjustment is not

available on the boiler, perform

it on the thermostatic valve.

> If there isn’t a thermostatic

valve, install a temperature

control device to make this

adjustment.

Put the installation into service.

Connection of a 230V/24V converter (not supplied)

230VAC

24VDC

A

B

1

Legend

1 230VAC / 24VDC relay

A Connection to control unit REL1

connector

B Connection to the 24V thermostat

connection of a boiler controlled by

contact

INTRODUCTION

EN