Maintenance – Glow-worm Clearly Heat Pumps 5kW User Manual

Page 26

0020096879_01 - 06/10 - Glow-worm

- 24 -

MAINTENANCE

b

IMPORTANT: any action carried out on the

refrigerant circuit must be performed by

qualified authorised personnel.

The refrigerant fluid contains gases that, when released into the

atmosphere, may affect the environment by depleting the ozone

layer, contributing to the greenhouse effect and an increase

in temperature. The risk of leakage cannot be excluded for

devices intended to operate for many years and subject to the

effects of the environment.

• See the "Safety instructions" chapter for a list of operations

to be performed prior to the maintenance of the application.

• Once the maintenance operations have been completed,

consult the ¨Start Up¨ chapter to restart the appliance.

16.1 Annual Maintenance

• Check the proper functioning of safety devices.

• Check the pressure of the water system.

• Check the airtightness of the cooling circuit.

• Check that there are no traces of rust or oil around the

cooling circuit’s components.

• Ensure that the appliance’s components are neither worn nor

broken.

• Check that the wires are firmly attached to the electrical

terminals.

• Check the appliance’s grounding.

• Check the starting temperature of the heat pump and the

adjustment points.

• Check the absence of ice in the compressor.

• Remove any dust from the power supply.

• Clean the air / refrigerant battery and make sure that air

circulates between the fins and around the unit.

• Check that the fan rotates freely.

• Check the pressure of the expansion vessel.

16.2 Draining

• Cut off the appliance’s electricity supply.

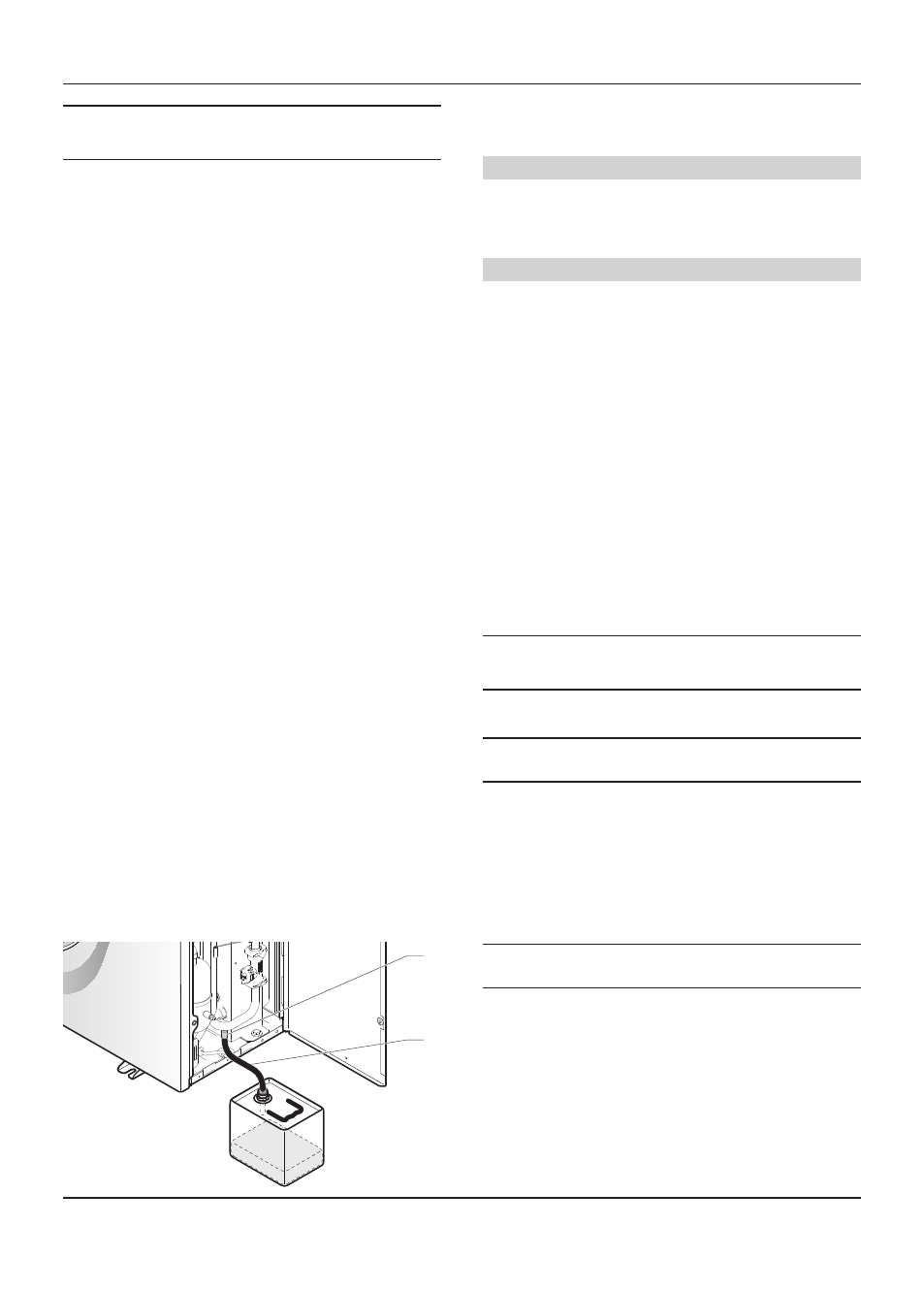

1

2

Key

1 Hydraulic circuit venting valve

2 Draining hose

Draining the hydraulic circuit

• Engage a hose (2) to the venting valve (1) or place a container

under the venting valve (1) to drain the hydraulic circuit.

• Open the venting valve (1) with an Ø 14 mm wrench.

Draining the appliance

• Close the shut-off valves located behind the heat pump.

• Engage a hose (2) to the venting valve (1) or place a container

under the venting valve (1) to drain the hydraulic circuit.

• Open the venting valve (1) with an Ø 14 mm wrench.

17 Replacement of Parts

• Do not use reconditioned or copy parts, only use original

parts supplied by Glow-worm.

• If a part is required, contact the Glow-worm service organisation.

• Please quote the name and serial number of the appliance,

this information will be on the data plate on the side of the

appliance.

• If in doubt seek advice from the local gas company or

Glowworm’s own service organisation.

a

Replacement of parts must be carried out by a

competent person approved at the time by the

Health and Safety Executive.

17.2.1

Mains supply cable

e

The main supply cable must be replaced by a

qualified and competent electrician.

• If the main supply cable is damaged, replace it refering to the

chapter "Electrical connection".

18 Spare parts

In order to guarantee the safe and prolonged life of the product,

manufacturers genuine spare parts must be used.

i

This appliance displays a CE Mark of conformity. Only

use the manufacturer’s genuine, new spare parts.

• Ensure that spare parts are correctly mounted in the right

position and direction. After fitting any spare part or servicing,

the appliance must be tested for its safe operation.